If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

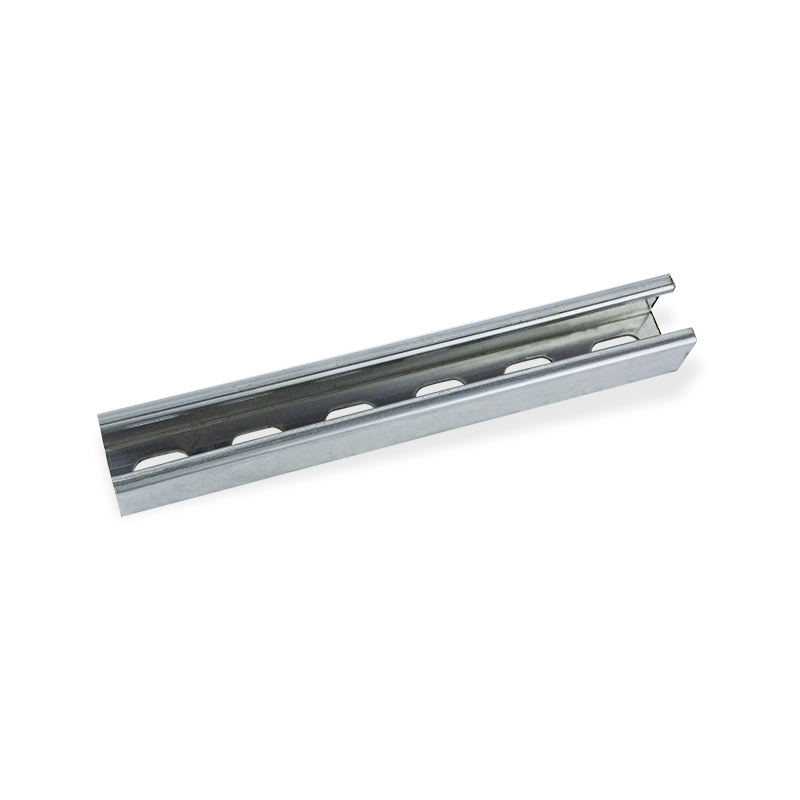

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

On August 1, 2025,Youming group organized an internal technical workshop , bringing together engineers, production teams, and quality control specialists to discuss cable tray manufacturing processes, quality improvement...

Photovoltaic (PV) brackets are critical components in solar panel installations, providing structural support and ensuring optimal energy efficiency. Choosing the right brackets affects system durability, safety, and per...

In modern electrical and network installations, cable management is crucial for safety, efficiency, and organization. One popular solution is the perforated cable tray, a versatile and durable option widely used in indus...

Why choose Industrial Aluminum Alloy Cable Tray System instead of traditional steel cable tray?

1. Natural anti-oxidation properties of aluminum alloy

The corrosion resistance of Industrial Aluminum Alloy Cable Tray System comes first from the natural anti-oxidation properties of aluminum alloy material itself. Compared with steel, aluminum alloy has a stronger ability to resist oxidation and corrosion. When aluminum alloy comes into contact with oxygen, it can spontaneously form a dense oxide film on the surface. This film not only has a strong protective effect, but also effectively blocks the intrusion of moisture, oxygen and other corrosive substances. This natural protection mechanism enables aluminum alloy to maintain stable performance during long-term use and avoids corrosion and damage caused by surface oxidation.

This natural anti-oxidation ability is especially suitable for humid environments. In traditional steel cable trays, due to the corrosiveness of steel, a rust layer is easily formed on the surface over time, affecting its appearance and structural safety. The Industrial Aluminum Alloy Cable Tray System can maintain a good appearance and structural stability for a long time even in a high humidity environment through the self-protection mechanism of aluminum alloy, greatly extending its service life.

2. Self-repair ability: Enhanced corrosion resistance

Another feature that makes the Industrial Aluminum Alloy Cable Tray System have an advantage in corrosion resistance is the self-repair ability of aluminum alloy. Once an oxide film is formed on the surface of aluminum alloy, if the film layer is damaged, the aluminum alloy material will self-repair in a short time to restore the integrity of its oxide layer. This means that in the case of slight mechanical damage or scratches, a new oxide film will quickly re-form on the surface of the aluminum alloy to resist external corrosive substances again.

This self-repair ability is very important, especially in cable tray systems that are exposed to harsh environments for a long time. Compared with traditional steel cable trays, this feature of aluminum alloy can effectively reduce corrosion problems caused by damage to the surface caused by the external environment. Even in highly corrosive environments such as high humidity and salt spray, the Industrial Aluminum Alloy Cable Tray System can maintain stable performance for a longer period of time, avoiding frequent maintenance and replacement.

3. Good chemical stability: resistance to acid and alkali corrosion

In addition to its excellent performance under moisture and oxygen corrosion, the Industrial Aluminum Alloy Cable Tray System also shows unique advantages in the face of chemical corrosion. The chemical stability of aluminum alloy materials themselves is high, and they can effectively resist the corrosion of most common corrosive chemicals such as acids and alkalis. In some chemical process flows, cable trays need to be exposed to the corrosion of acid and alkali substances for a long time, which is undoubtedly a huge challenge for traditional steel cable trays.

4. Improve service life and reduce maintenance requirements

Due to the excellent corrosion resistance of the Industrial Aluminum Alloy Cable Tray System, especially its stability in harsh environments, its service life is longer than that of traditional steel cable trays. Traditional steel cable trays require regular anti-corrosion treatment, painting and other maintenance measures to maintain their normal functions. Aluminum alloy cable trays can be in working condition for a long time without frequent maintenance, greatly reducing daily maintenance needs and related costs.

For a long time, the corrosion problem of cable tray systems has been a major burden in the maintenance costs of enterprises, especially in corrosive environments. However, the corrosion resistance of Industrial Aluminum Alloy Cable Tray System can effectively avoid cable damage and system failures caused by rust, reduce the maintenance frequency and replacement costs of enterprises, and ensure the continuous stability of the power system.

5. Adapt to extreme environments and improve system reliability

In modern industrial environments, cable tray systems are more and more widely used, but the requirements for cable trays are also getting higher and higher, especially in some harsh industrial environments. Humid climate, chemical corrosion, marine climate and other factors may pose a threat to cable trays. The performance of Industrial Aluminum Alloy Cable Tray System in these environments far exceeds that of traditional steel trays. Its excellent corrosion resistance and self-healing ability make it an ideal choice to ensure the efficient operation of power transmission systems and avoid equipment failures and safety hazards caused by cable tray corrosion.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt