If you need any help, please feel free to contact us

Stainless Steel Wire Tray: The Core Choice for Modern Wiring Systems

In modern buildings and industrial facilities, the safety, efficiency, and reliability of wiring systems are paramount. The stainless steel wire tray, with its excellent material properties and flexible design, has become the core choice for ensuring the long-term stable operation of the entire cable network. It is not just a simple load-bearing tool, but an art of wiring that balances engineering aesthetics with practical functionality.

Unique Advantages and Performance Comparison of Stainless Steel Wire Trays

The stainless steel wire tray stands out from other materials due to its unique physical and chemical properties.

- Excellent Corrosion Resistance: Stainless steel (especially grades 304 and 316) can effectively resist erosion from harsh environments such as moisture, salt spray, acids, and alkalis, making it an ideal choice for specific industries like chemical plants and coastal facilities.

- Outstanding Mechanical Strength and Load Capacity: The high strength and hardness of stainless steel can support a large number of cables while resisting external impacts, ensuring the physical safety of the wiring system.

- Superior Fire Performance: Stainless steel is a non-combustible material with a high melting point, allowing it to effectively support cables during a fire, gaining valuable time for firefighting and evacuation.

- Good Electromagnetic Compatibility (EMC): The open-grid structure helps shield against electromagnetic interference, protecting sensitive cables and ensuring stable data transmission.

Performance Comparison with Other Materials

To better understand its superiority, here is a comparison of stainless steel wire trays with common cable tray materials:

| Feature | Stainless Steel (304/316) | Galvanized Steel | Aluminum Alloy | PVC (Polyvinyl Chloride) |

| Corrosion Resistance | Excellent | Fair | Good | Poor |

| Load Capacity | High | Relatively High | Low | Very Low |

| Fire Performance | Excellent | Good | Fair | Very Poor |

| Installation Flexibility | Good | Good | Fair | Fair |

| Service Life | Long | Medium | Relatively Long | Short |

Design and Installation: The Art of Wiring with Stainless Steel Wire Trays

The design philosophy of stainless steel wire trays is to simplify wiring work while ensuring the long-term stability of the system.

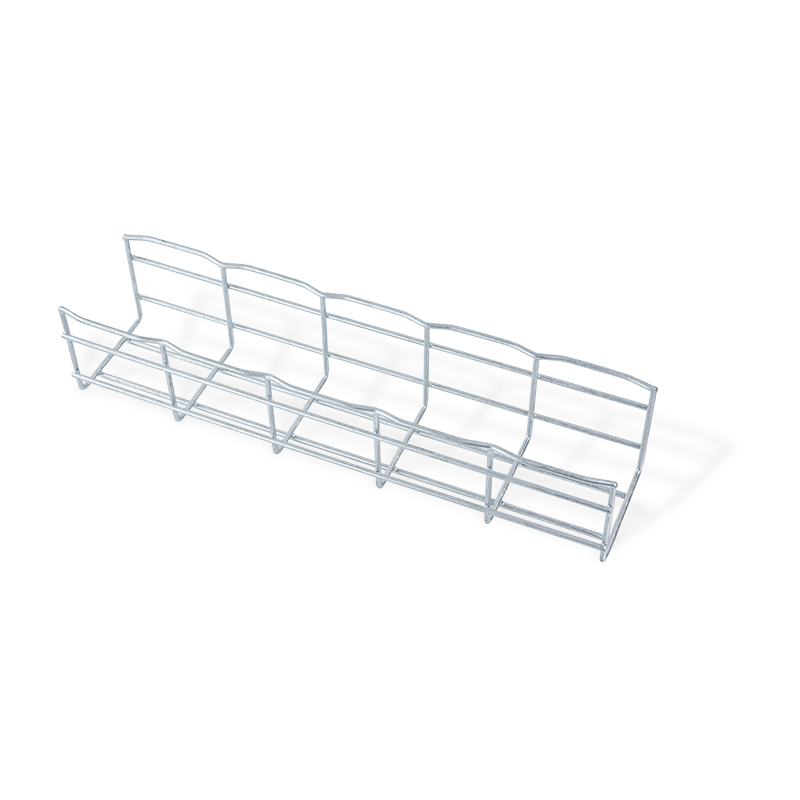

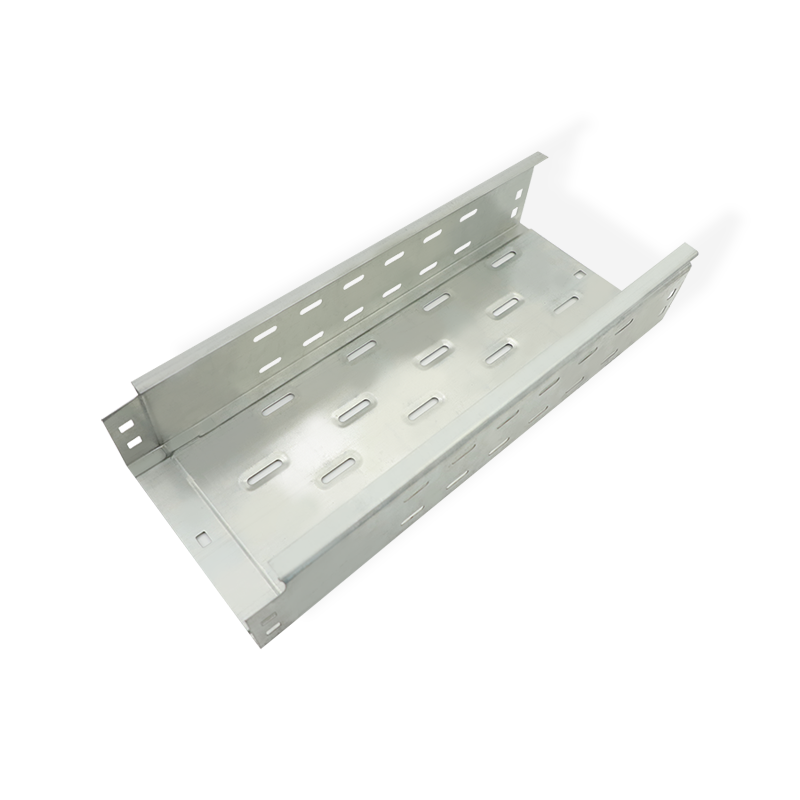

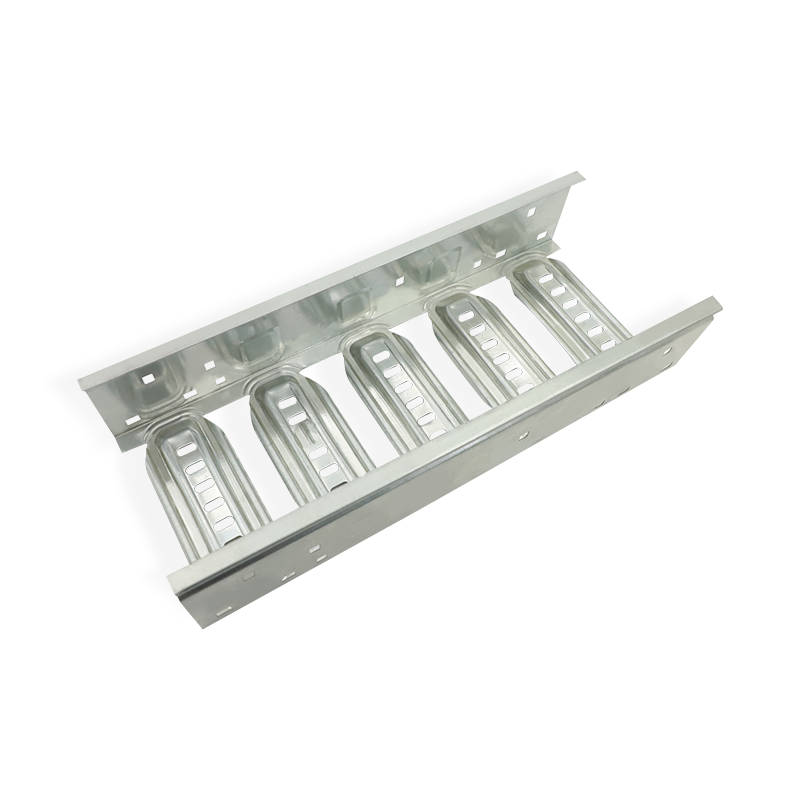

Open-Grid Design: The Secret to Ventilation and Heat Dissipation

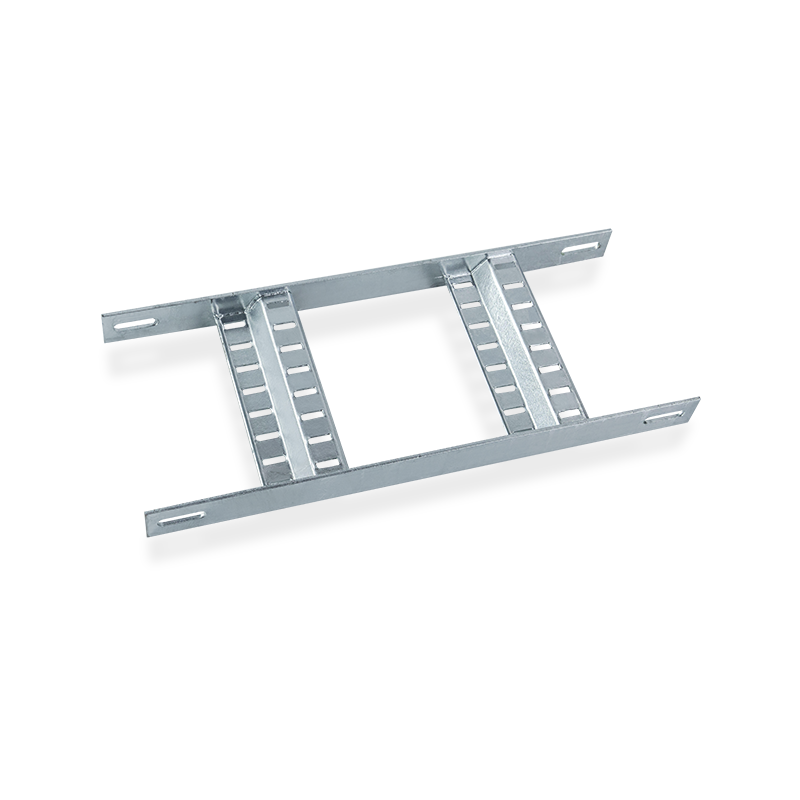

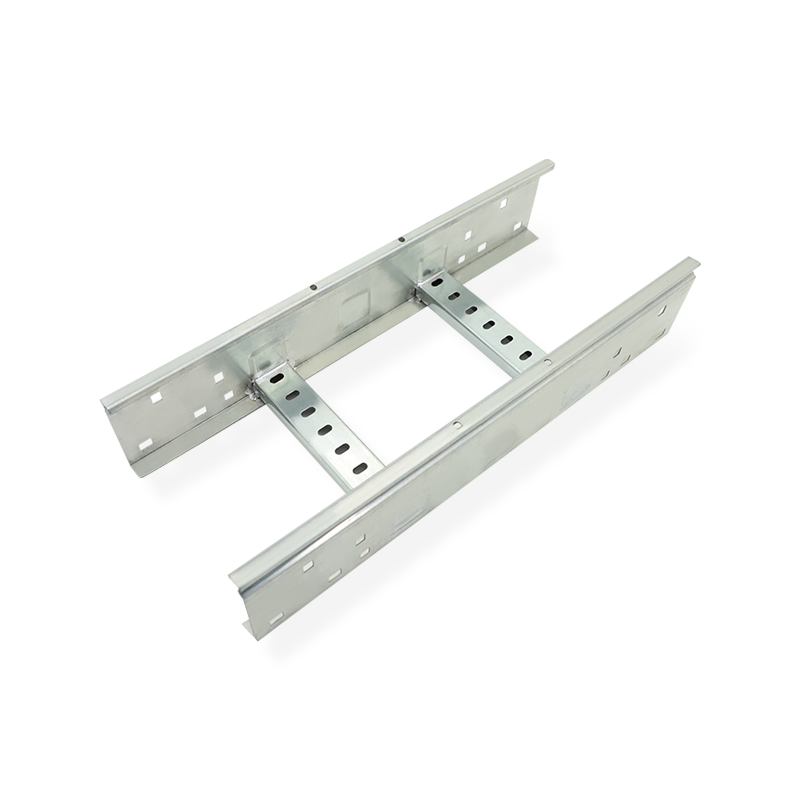

The open-grid or ladder-type structure of stainless steel wire trays is a key feature. This design:

- Efficiently Dissipates Heat: It increases the contact area between cables and the air, creating good natural ventilation and reducing cable temperature, which extends cable life.

- Facilitates Maintenance: The visible cable layout allows for easy inspection, addition, or removal of cables without dismantling the entire system, greatly improving efficiency.

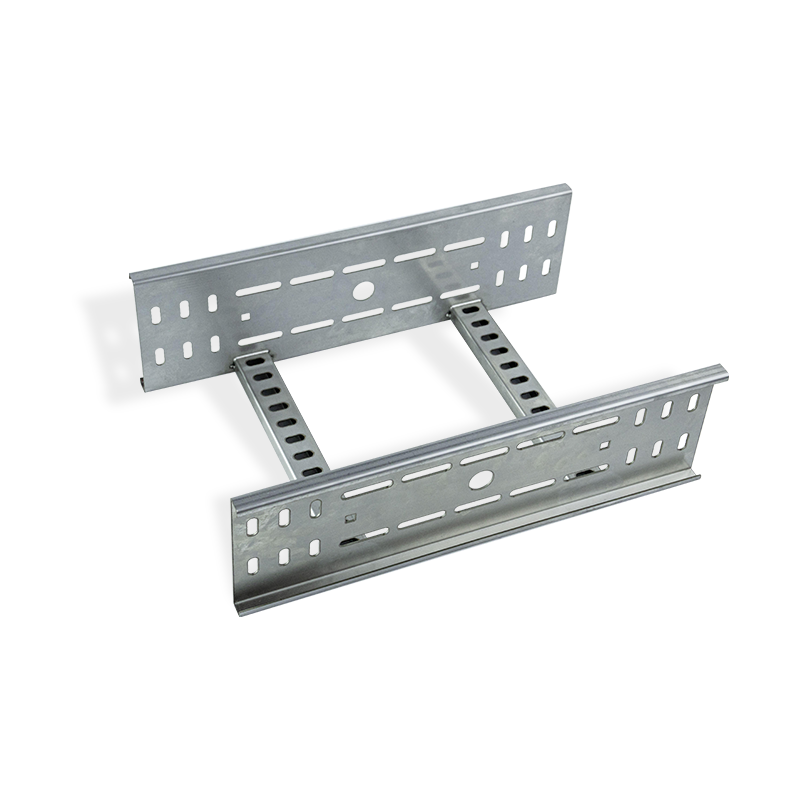

Flexible Installation and Customization

The installation process for stainless steel wire trays is modular and efficient, with various standardized components and connection methods that can easily adapt to complex wiring paths.

Comparison of Different Installation Methods

| Installation Method | Load Capacity | Application Scenarios | Advantages | Disadvantages |

| Ceiling Mounted | High | Large spans, high load-bearing requirements | Strong stability, high load capacity | Complex installation |

| Wall Mounted | Medium | Wiring along walls, moderate cable quantity | Space-saving, relatively simple installation | Limited by wall load capacity |

| Floor Mounted | High | Rapid, temporary wiring, where other methods are not possible | Quick installation, easy to adjust | Occupies floor space, prone to damage |

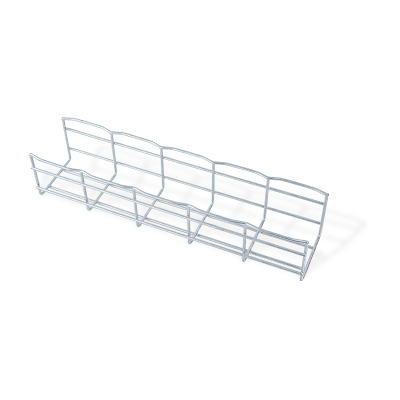

Wave wire mesh cable tray/cureved side wire

Safety and Maintenance: Long-Term Assurance of Stainless Steel Wire Trays

The long-term safety and ease of maintenance of stainless steel wire trays are their core value. Companies like Jiangsu Youming Group Co., Ltd., ensure these features through strict production and quality control.

Comprehensive Safety Protection

The safety of stainless steel wire trays is a multi-faceted guarantee:

- Fire Resistance: The high melting point of stainless steel ensures structural integrity during a fire.

- Corrosion Resistance and Moisture Protection: This property protects cable insulation from degradation in harsh environments.

- Physical Protection: The robust structure prevents cables from mechanical damage, such as impacts or rodent bites.

Simplified Daily Management

The maintenance benefits of stainless steel wire trays significantly reduce the life-cycle cost of the entire wiring system.

- Easy to Clean: The smooth surface is easy to wipe or rinse, which is crucial for industries with high hygiene standards.

- Convenient Inspection: The open design allows for quick visual inspections, making it easy to troubleshoot or add cables without complex procedures.

- Durability and Low Replacement Cost: The long service life of stainless steel means the system rarely needs replacement, representing a long-term investment.

Comparison of Quality and Long-Term Assurance Parameters

| Parameter | High-Quality Stainless Steel Tray | Ordinary Stainless Steel Tray |

| Material Purity | Compliant with international standards, stable performance. | May use impure or recycled steel. |

| Surface Treatment | Advanced passivation for superior corrosion resistance. | May be omitted or use simple treatments. |

| Welding Strength | Fully automatic welding, high strength. | Variable quality, potential for weak welds. |

| Dimensional Accuracy | Precise dimensions from laser cutting and CNC. | Dimensional deviation and burrs. |

| Load Testing | Rigorous testing with safety margins. | Lack of strict testing. |

The stainless steel wire tray is the ideal choice for modern wiring systems due to its material advantages, design flexibility, and long-term maintenance benefits. Choosing a company like Jiangsu Youming Group Co., Ltd., with strong production capabilities and strict quality control, ensures a safe, efficient, and durable cable management solution.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt