If you need any help, please feel free to contact us

Punched Perforated Cable Tray vs. Other Cable Management: Core Advantages in Load Capacity, Heat Dissipation, and Installation Efficiency

Choosing the right cable management system is crucial for the safety and efficiency of any electrical installation. While there are many options available, the punched perforated cable tray stands out for its unique benefits. This article will dive deep into its core advantages, comparing it to common alternatives like cable trunking and wire mesh trays to help you make an informed decision for your next project.

Why the Punched Perforated Cable Tray is a Superior Choice

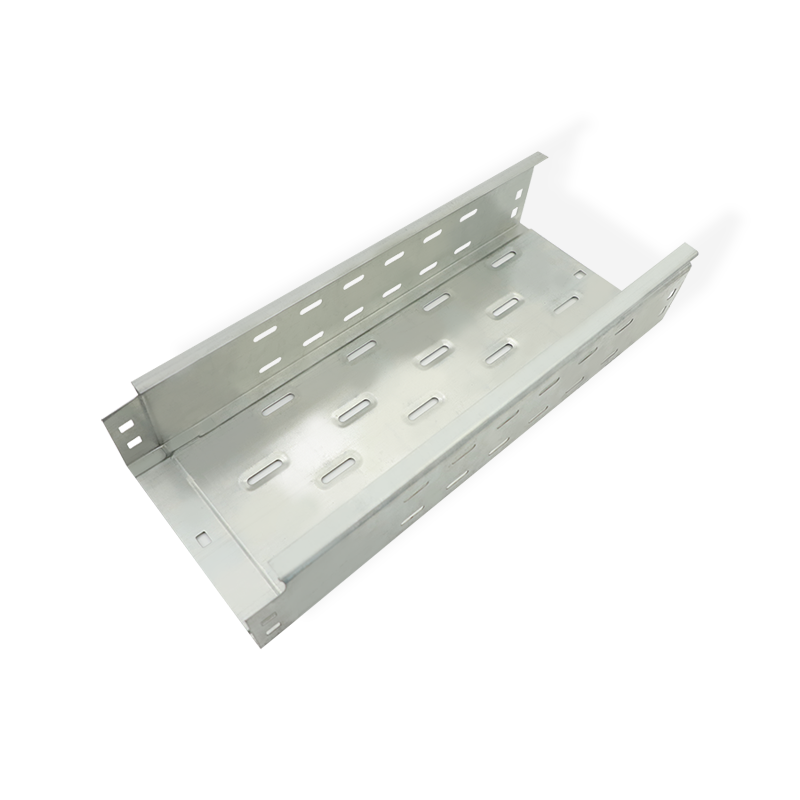

The punched perforated cable tray system is a versatile and reliable solution engineered to meet the demands of modern electrical installations. Its design, which combines a solid base with strategic perforations, offers a balanced approach to supporting and protecting cables. The following sections will explore the specific technical and practical benefits that make it a preferred option for a wide range of applications, from industrial factories to data centers.

Enhanced Load Capacity and Structural Integrity

The load-bearing capability of a cable tray is paramount, particularly in environments with dense cable layouts. The design of a perforated tray ensures exceptional strength and rigidity.

-

Engineered for High-Stress Environments

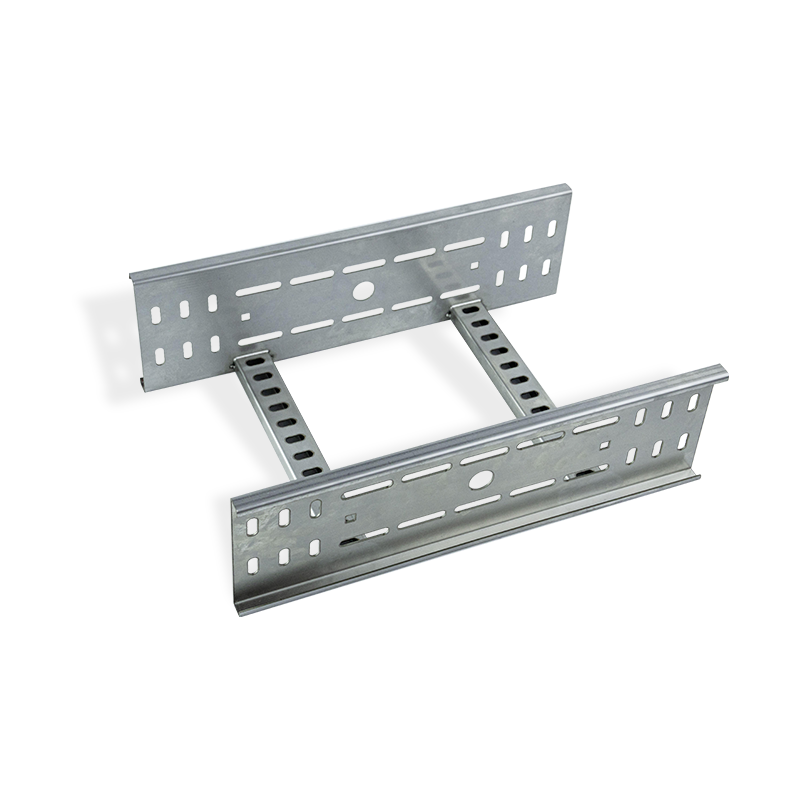

The punched perforated cable tray is typically manufactured from a single sheet of metal with a continuous solid bottom and folded side rails. This design provides a robust backbone capable of supporting significant weight without warping or bending. For large-scale data centers or industrial applications that require dense cable runs, a heavy duty perforated cable tray is often the top choice.

-

Comparative Strength Parameters

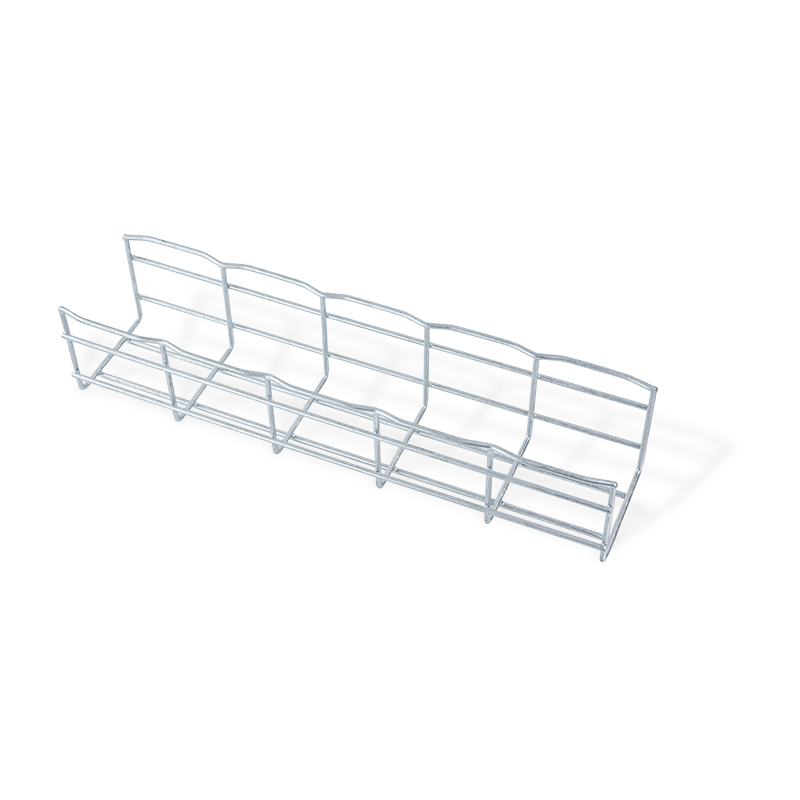

Compared to a wire mesh tray, which is generally better for lighter loads and quick installations, the perforated tray offers superior rigidity and support for a larger number of cables. While cable trunking also offers high strength, its closed design limits its flexibility and ventilation. According to industry standards such as NEMA VE 1 or IEC 61537, these trays often meet or exceed a Class 2 load rating, making them suitable for long support spans and heavy loads.

| Feature | Punched Perforated Cable Tray | Wire Mesh Tray | Cable Trunking |

| Structural Rigidity | High (solid sheet construction) | Medium (welded wire structure) | Very High (closed box) |

| Load Distribution | Excellent (even support across the base) | Good (varies based on wire thickness) | Excellent (even support across the base) |

| Load Ratings (General) | High, Class 2 (NEMA VE 1) | Medium, Class 1 (NEMA VE 1) | High, can exceed Class 2 |

Superior Heat Dissipation and Airflow

Effective heat management is vital for extending the lifespan of cables and preventing system failures. The perforated design of these trays is key to their thermal performance.

-

Optimized for Thermal Management

The strategic perforations on the bottom surface of the tray act as vents, allowing air to circulate freely around the cables. This prevents heat from building up, which is a common issue in closed systems like cable trunking. This feature is a primary reason for using a perforated tray for electrical wires in warm or high-density environments, such as server rooms and motor control centers.

-

Key Airflow Parameters

The effectiveness of heat dissipation is directly related to the open area of the tray. A typical punched perforated cable tray has an open area of between 15% and 30%, which significantly reduces temperature rise. For example, a tray with a 20% open area can lead to a temperature reduction of 15% to 20% compared to a solid-bottom tray. Wire mesh trays, with a much higher open area (over 80%), offer superior passive ventilation. However, closed cable trunking systems have virtually no open area, trapping heat and increasing the risk of insulation degradation and reduced cable ampacity.

| Feature | Punched Perforated Cable Tray | Wire Mesh Tray | Cable Trunking |

| Heat Dissipation | Excellent (controlled airflow) | Superior (maximum airflow) | Poor (no ventilation) |

| Open Area | 15%-30% | >80% | 0% |

Enhanced Installation Efficiency and Customization

A major factor in project completion and cost is the ease and speed of installation. The design of the punched perforated cable tray system is built for efficiency and adaptability.

-

Faster Installation with Pre-Punched Holes

One of the most significant time-savers is the presence of pre-punched holes in the tray's bottom and sides. These holes are designed to accommodate a wide variety of fasteners, eliminating the need for on-site drilling. This makes for a truly easy install perforated cable tray, reducing labor costs and project timelines. The precision of the factory-made holes also ensures a secure and compliant installation every time.

-

Adaptable and Versatile Design

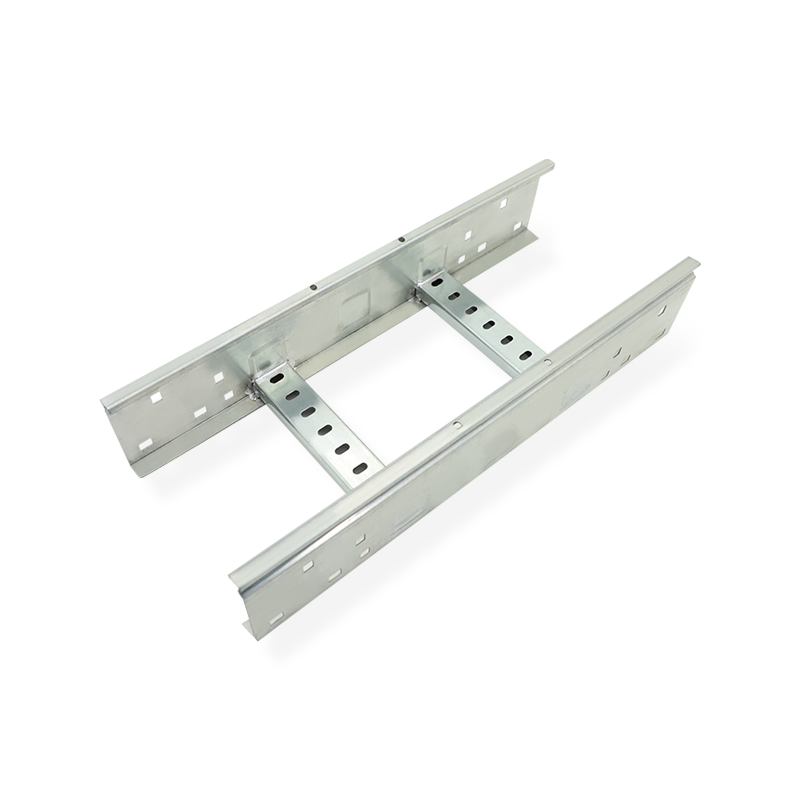

The modular nature of the system, combined with a comprehensive range of accessories, allows for a high degree of customization. Whether you need to make a bend, a T-junction, or a reducer, a perforated cable tray with fittings can be assembled to fit complex routes and layouts with ease. This adaptability makes it a truly versatile perforated cable tray that can accommodate last-minute design changes and complex routing requirements in both horizontal and vertical planes.

| Feature | Punched Perforated Cable Tray | Wire Mesh Tray | Cable Trunking |

| Installation Speed | Fast (no drilling needed for fittings) | Very Fast (quick connectors) | Slow (requires precise measurement and cutting) |

| Ease of Modification | High (easy to cut, bend, and attach fittings) | Very High (can be shaped by hand) | Low (requires specialized tools for bends) |

A Balanced Solution for Modern Projects

In summary, the punched perforated cable tray offers a powerful combination of robust structural support, superior thermal management, and streamlined installation. By providing a solid yet ventilated platform for cables, it helps to ensure the long-term reliability and safety of your electrical infrastructure. When a project demands high load capacity, efficient heat dissipation, and a system that is both quick to install and easy to modify, a perforated cable tray with fittings is an excellent investment that balances performance and practicality.

Frequently Asked Questions (FAQ)

1. What are the main product series and specifications of your punched perforated cable trays?

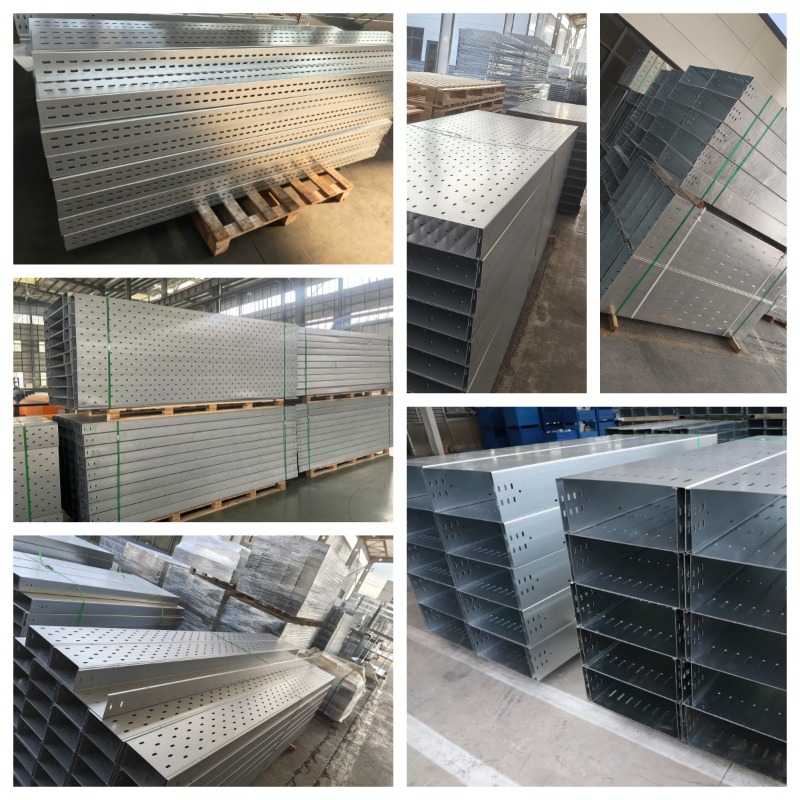

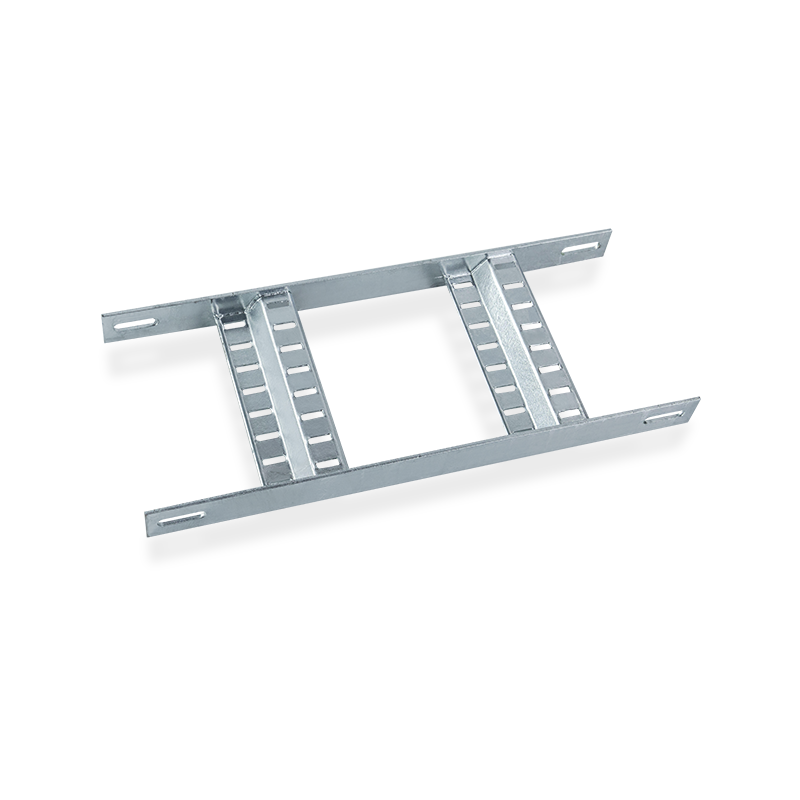

Our punched perforated cable tray product line is extensive, designed to meet the demands of various complex environments. We primarily offer several series, including stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof. These products are available in various specifications and models, such as trough, ladder, perforated, and mesh types. They are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic, and thermal power), machinery, metallurgy, shipping, chemical, pharmaceutical, and food industries, ensuring you have the right solution for your project.

2. How does your company ensure the load capacity and product quality of your punched perforated cable trays?

We understand the importance of product quality and load capacity for project safety. As an enterprise specializing in the R&D and production of cable trays, Jiangsu Youming Group Co., Ltd. is equipped with advanced fully automatic production lines, including longitudinal and transverse shearing, automatic forming, automatic welding, and laser cutting equipment, which ensures the precision of our manufacturing. Furthermore, our company has its own testing center where every step, from raw material procurement to product delivery, undergoes strict quality inspection to ensure our products meet the highest industry standards.

3. In what ways does Jiangsu Youming Group Co., Ltd. demonstrate its industry leadership?

Jiangsu Youming Group Co., Ltd. was established in 2015 and is a recognized innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB and a production workshop of over 26,000 square meters, we boast an annual production capacity of more than 30,000 tons of cable trays. The company's fully automated production lines and rigorous quality control processes have allowed us to steadily advance to the forefront of the increasingly refined cable tray market. We not only provide a wide range of materials and types of cable trays but have also established strong cooperative relationships with many renowned domestic enterprises, offering customers comprehensive product selection services and earning their high recognition and trust.

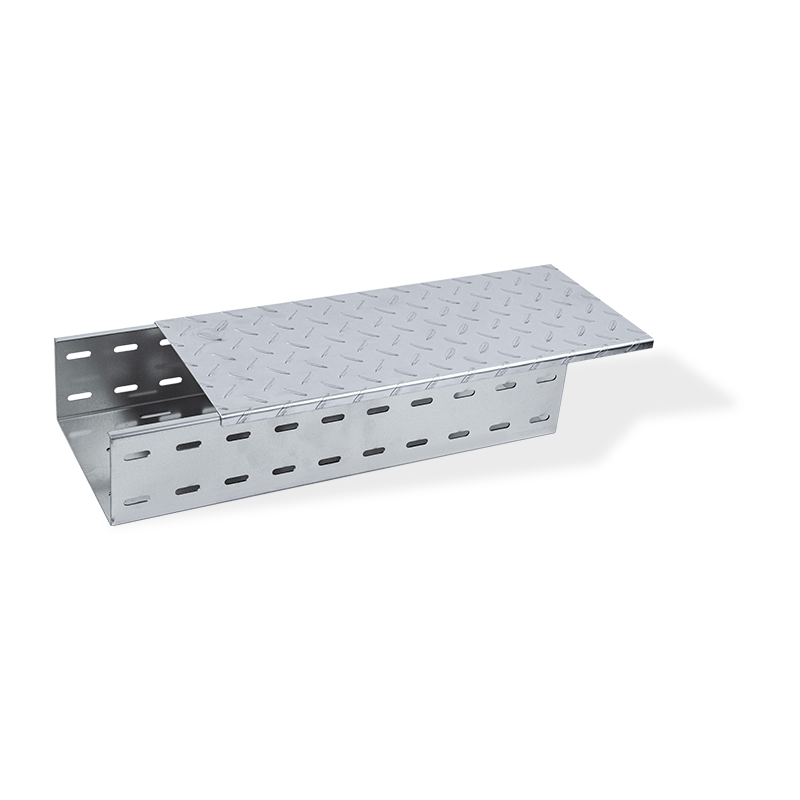

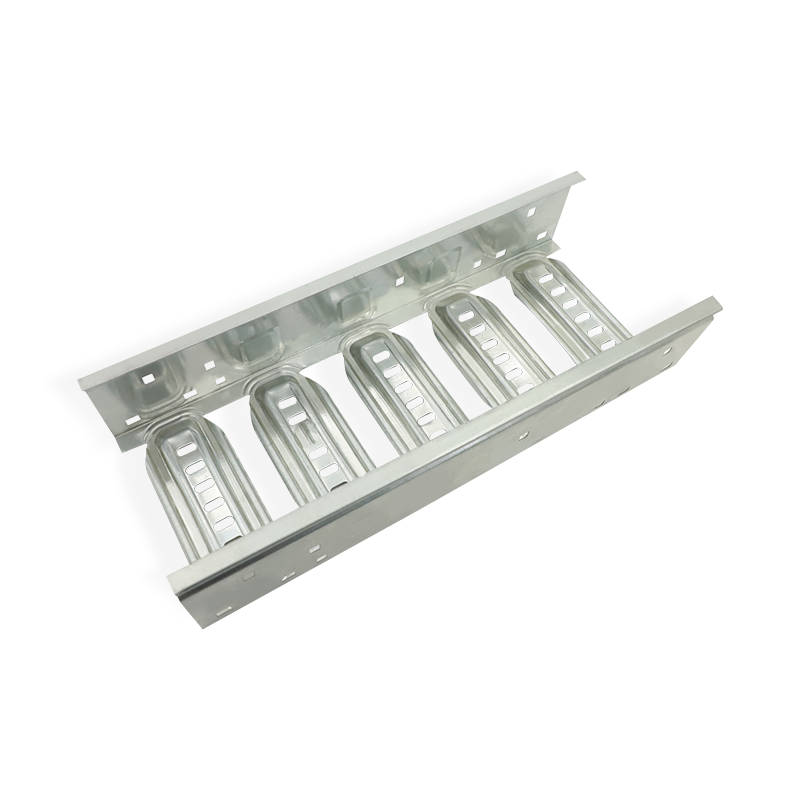

Cable tray with flower-typed anti-slippery and anti-grinding

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt