If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

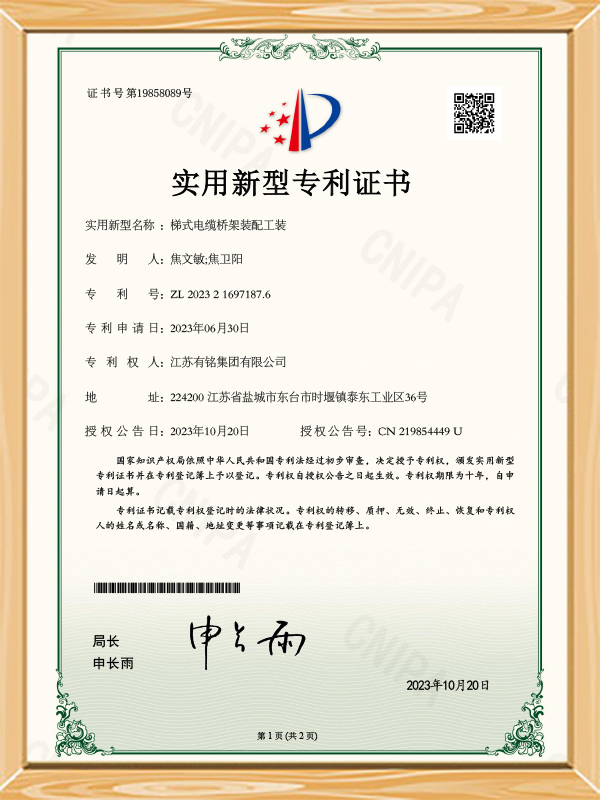

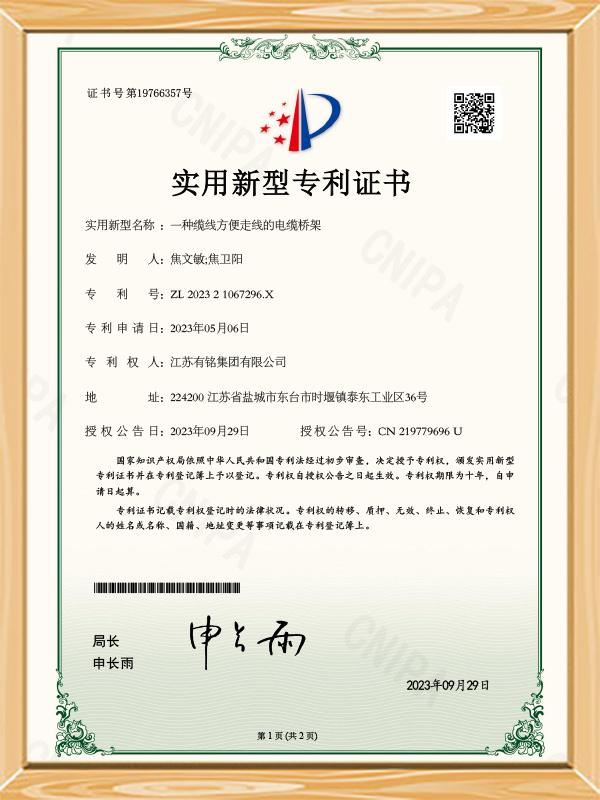

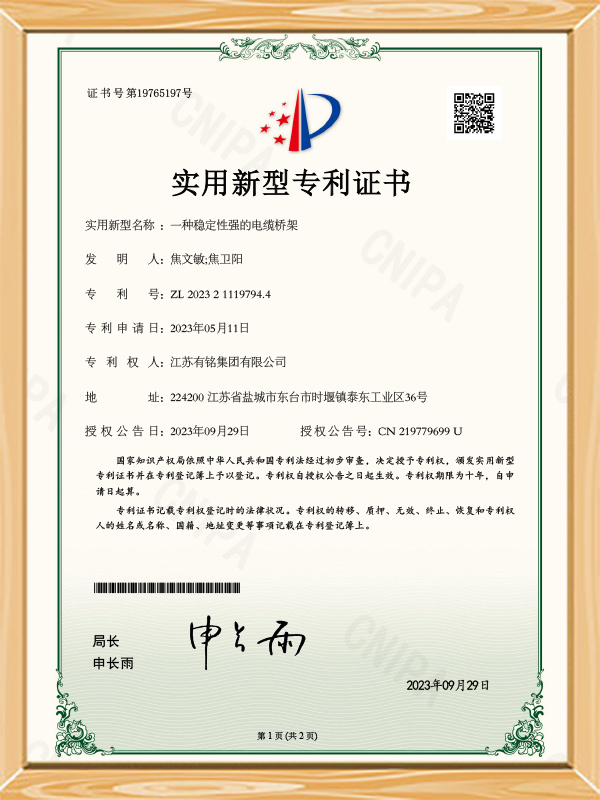

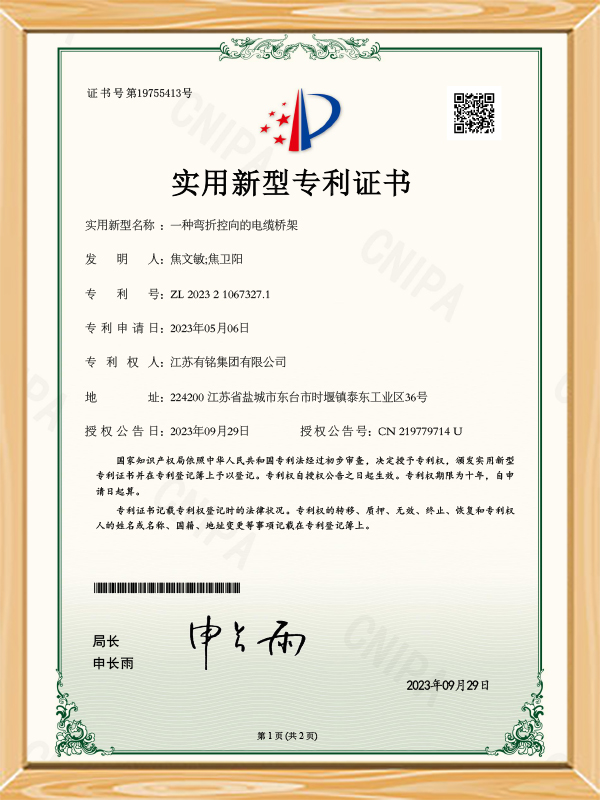

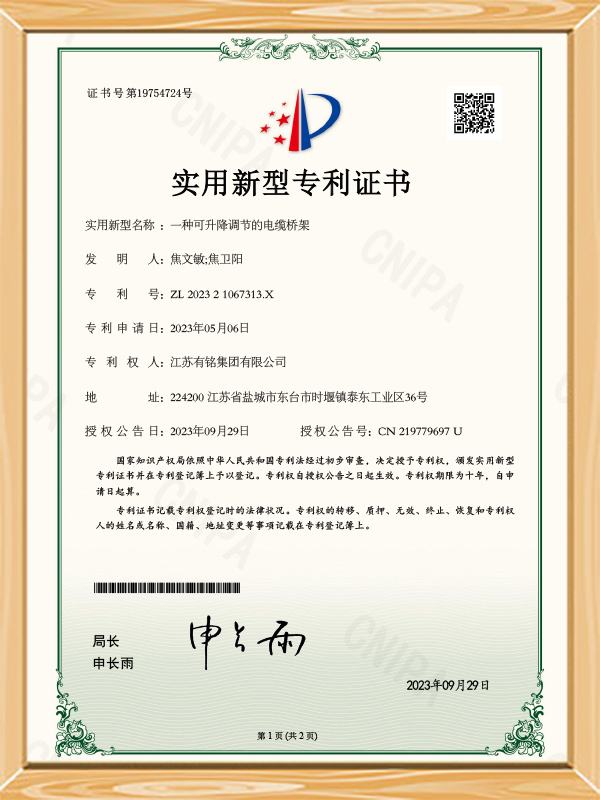

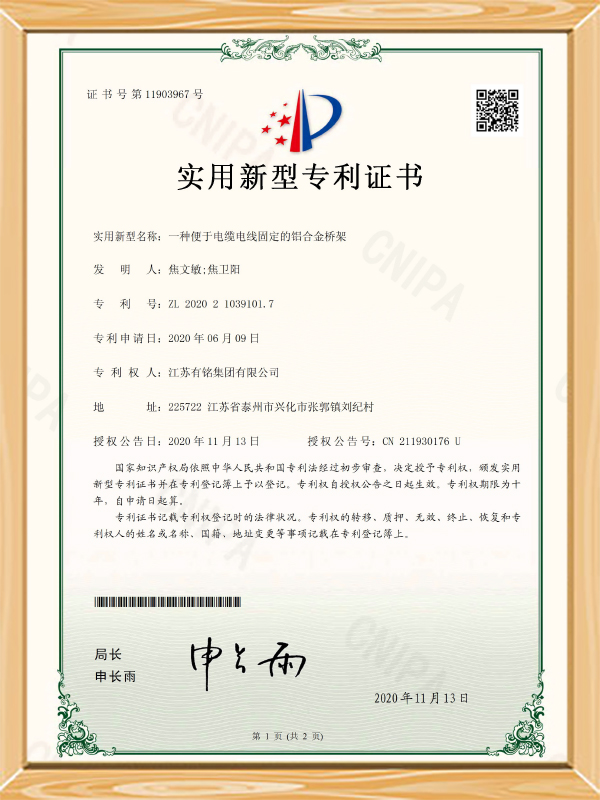

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Choosing the right cable management system is crucial for the safety and efficiency of any electrical installation. While there are many options available, the punched perforated cable tray stands out for its unique bene...

In modern buildings and industrial facilities, the safety, efficiency, and reliability of wiring systems are paramount. The stainless steel wire tray, with its excellent material properties and flexible design, has becom...

In the world of industrial cable tray manufacturing, precision and reliability are non-negotiable. At Youming group, we believe these standards are achieved not just through advanced machinery, but through the unbreakab...

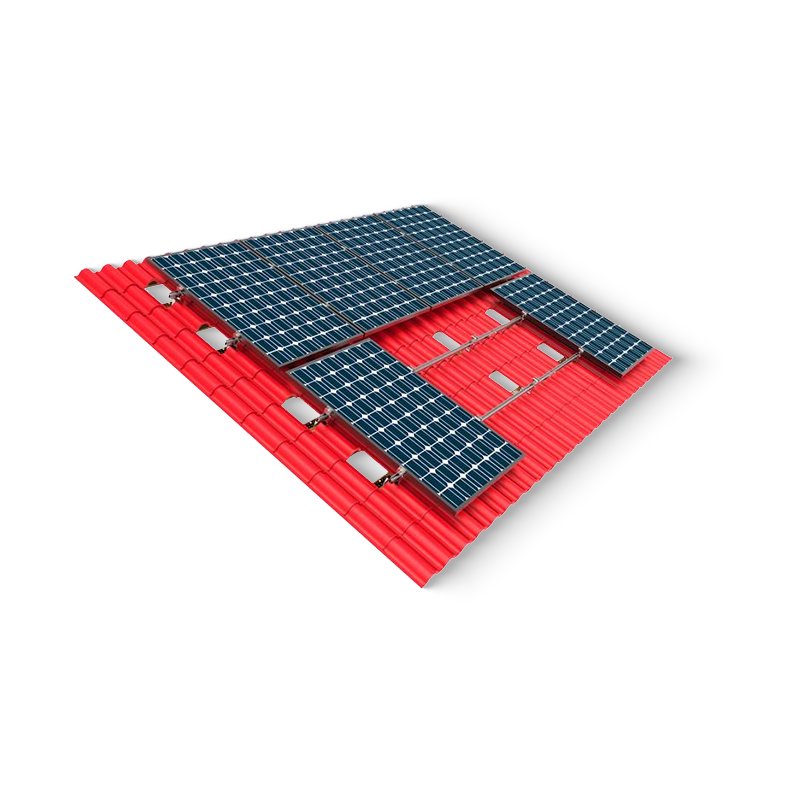

Can Outdoor Photovoltaic Stents cope with the challenges of extreme weather?

1. Extreme weather challenges in outdoor environments

In outdoor environments, photovoltaic brackets are often exposed to adverse weather conditions such as wind, rain, snow, ultraviolet rays, and humidity. How to ensure that the bracket operates stably under these extreme conditions has become a challenge that cannot be ignored in photovoltaic systems. The main function of the bracket is to support the photovoltaic panel and ensure that the panel is at the best angle to improve the power generation efficiency of the photovoltaic system. However, extreme weather not only places higher requirements on the structural stability of the bracket, but also requires the bracket to withstand strong external pressure.

Especially in strong wind environments, the bracket must be able to resist huge lateral wind forces, otherwise the photovoltaic panel will not be able to maintain a stable angle, and in severe cases it may even cause the panel to shift or fall, causing the photovoltaic system to fail. At this time, the material strength of the bracket directly determines whether it can withstand these external pressures and ensure the stable operation of the photovoltaic system. Therefore, the strength and stability of the photovoltaic bracket are the basis for ensuring the performance of the entire system.

2. Material selection: dual guarantee of strength and durability

In the process of dealing with extreme weather, the selection of bracket material is crucial. The mainstream materials of Outdoor Photovoltaic Stents include high-strength alloy steel, aluminum alloy and stainless steel. These materials have good mechanical strength and can effectively withstand the pressure applied by the outside world. At the same time, they can resist the influence of long-term exposure to harsh environmental factors such as wind, rain, and ultraviolet rays to maintain their structural stability.

The application of high-strength alloy steel in photovoltaic brackets mainly depends on its excellent load-bearing capacity and high pressure resistance. Due to its high density, alloy steel can better disperse the pressure applied by the outside world and prevent the bracket from deforming under the influence of strong winds and heavy snow. Aluminum alloy has gradually become a common material in Outdoor Photovoltaic Stents due to its lightness and corrosion resistance. Aluminum alloy can not only provide sufficient strength support, but also show strong corrosion resistance when exposed to outdoor environment for a long time, which makes aluminum alloy brackets have better durability when dealing with rain and ultraviolet rays.

In addition, stainless steel is also a commonly used high-quality material for brackets, especially suitable for environments with heavy humidity or high salt content. Its excellent corrosion resistance and oxidation resistance can ensure that the bracket is not easily affected by moisture, corrosion or damage during long-term use, further extending its service life.

3. High-strength alloy steel and aluminum alloy: performance in windy environments

In environments with extreme wind speeds, photovoltaic brackets must have sufficient strength to withstand the lateral pressure caused by wind. If the strength of the bracket material is insufficient, the bracket may deform or even break, which will affect the stability of the photovoltaic panel. This will not only reduce the power generation efficiency of the photovoltaic system, but may also cause equipment damage in severe cases.

In order to meet this challenge, many photovoltaic brackets are made of high-strength alloy steel or aluminum alloy. The high-strength alloy steel has a compact structure and strong compressive resistance, which can effectively disperse the lateral pressure caused by wind and prevent the bracket from deforming in strong wind environments. Aluminum alloy brackets are lightweight and have sufficient strength to stably support photovoltaic panels under strong wind conditions. Through optimized design, these brackets can not only share the pressure of wind, but also ensure the stability of the angle of the photovoltaic panel and ensure the normal operation of the photovoltaic system.

4. Elasticity and resilience: Coping with impact and deformation

In addition to strength, the elasticity and resilience of photovoltaic brackets are also key factors in whether they can cope with extreme weather. Unlike traditional rigid materials, modern photovoltaic bracket materials pay more attention to elastic properties when designing to enhance the recovery ability of the bracket when encountering severe impact. When encountering strong winds or other external forces, the bracket may produce slight deformation. At this time, the elasticity of the material can effectively absorb the external force and restore the bracket to its original state, thereby avoiding bracket failure due to

brittle cracking or permanent damage of the material.

Materials such as high-strength alloy steel and aluminum alloy perform well in elasticity. They not only have high mechanical strength, but also have a certain elasticity, which can effectively relieve external pressure. When the bracket encounters impact in storms or other extreme weather, these materials can quickly restore their original form, prevent the photovoltaic system from suffering from long-term operational instability, and ensure the long-term stability of the equipment.

5. Long-term durability and innovative design of photovoltaic brackets

With the continuous advancement of technology, the materials and designs of photovoltaic brackets are also being optimized. In the future, Outdoor Photovoltaic Stents will not only rely on traditional materials such as high-strength alloy steel, aluminum alloy and stainless steel, but may also introduce more innovative materials to further enhance the strength and stability of the bracket. For example, the application of composite materials and high-performance polymers can reduce the weight of the bracket while ensuring the strength of the bracket, and further enhance the wind resistance and impact resistance of the bracket.

At the same time, with the increasing diversification of the needs of photovoltaic systems, bracket design is also moving towards a more intelligent and modular direction. By integrating intelligent monitoring technology, the bracket can detect wind speed, temperature and other external factors in real time, automatically adjust the structure and angle, and respond to environmental changes in the best way, thereby further improving the stability and efficiency of the bracket.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt