If you need any help, please feel free to contact us

Aluminum Alloy Cable Tray Installation Guide: Step-by-Step Process

Introduction to Aluminum Alloy Cable Trays

Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely used in industrial settings to support cables, ensuring both safety and ease of maintenance. Their use has grown over traditional steel trays due to aluminum's benefits, such as its ability to withstand extreme temperatures and resist chemical damage. These trays play a critical role in managing electrical wiring systems efficiently, which is crucial for maintaining safe and organized environments.

- Corrosion resistance for long-term durability

- Lightweight design for easier installation

- Cost-effective solution for wiring systems

- Flexible in various industrial applications

Preparing for Installation

Proper planning and preparation are vital for a successful installation of aluminum alloy cable trays. Before beginning the installation, ensure that you have the right tools and materials at hand. Also, consider the type of cable tray required for your specific project, as well as the layout and the electrical needs of your facility. Careful planning at this stage can prevent costly mistakes and unnecessary delays.

- Ensure all materials are readily available.

- Double-check the layout and measurement plans.

- Inspect the space for installation to ensure proper cable tray sizing.

- Confirm the load capacity of the chosen aluminum alloy tray.

Selecting the Right Aluminum Alloy Cable Tray

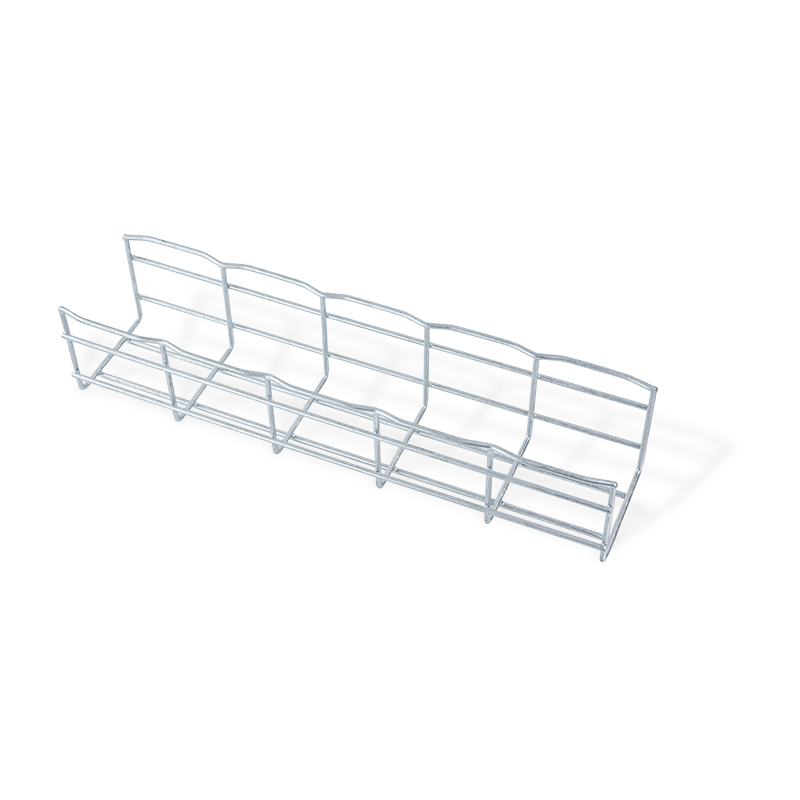

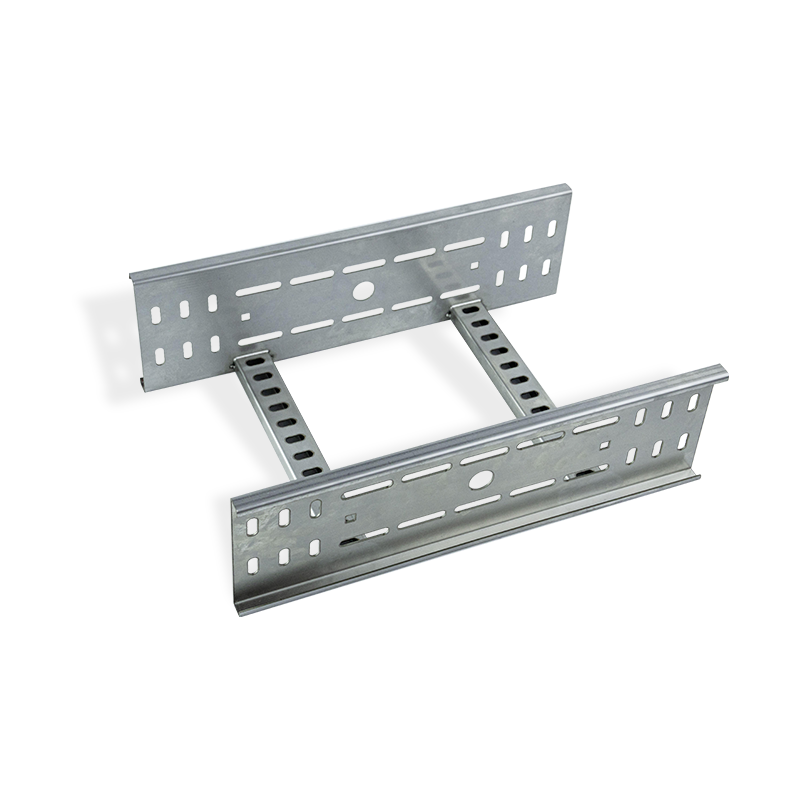

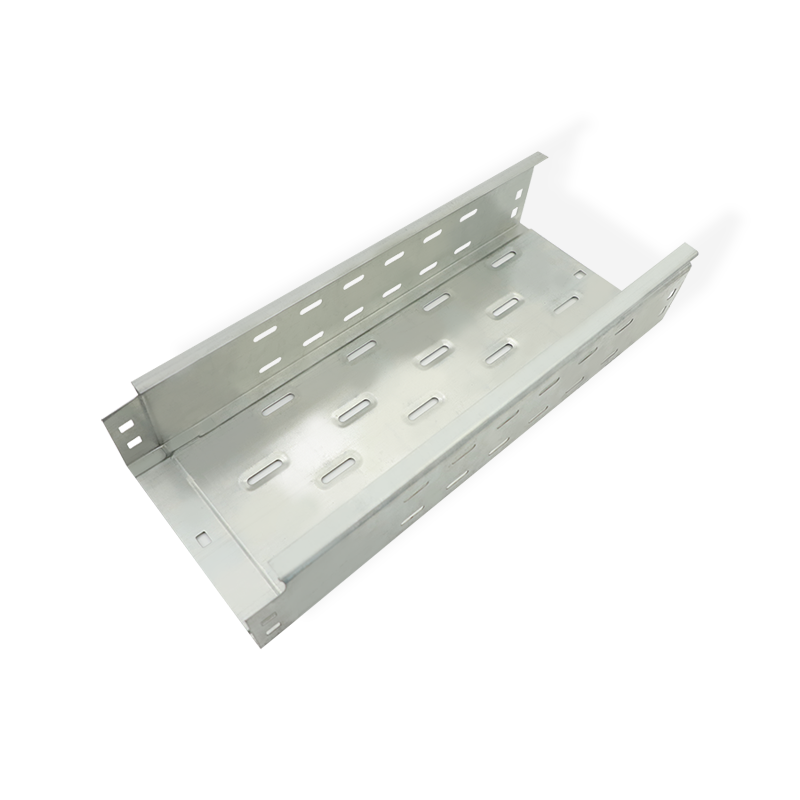

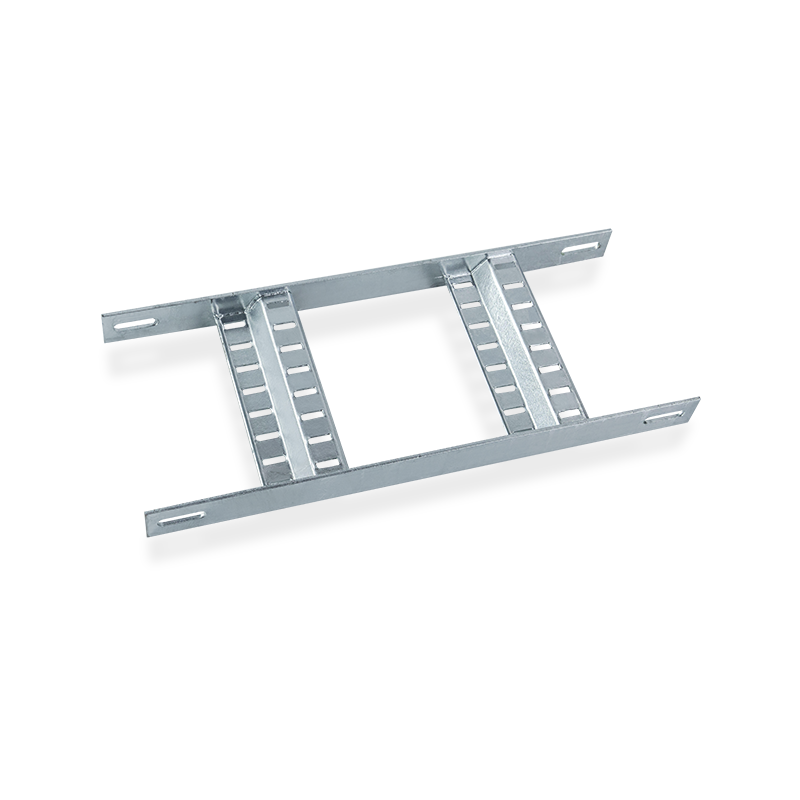

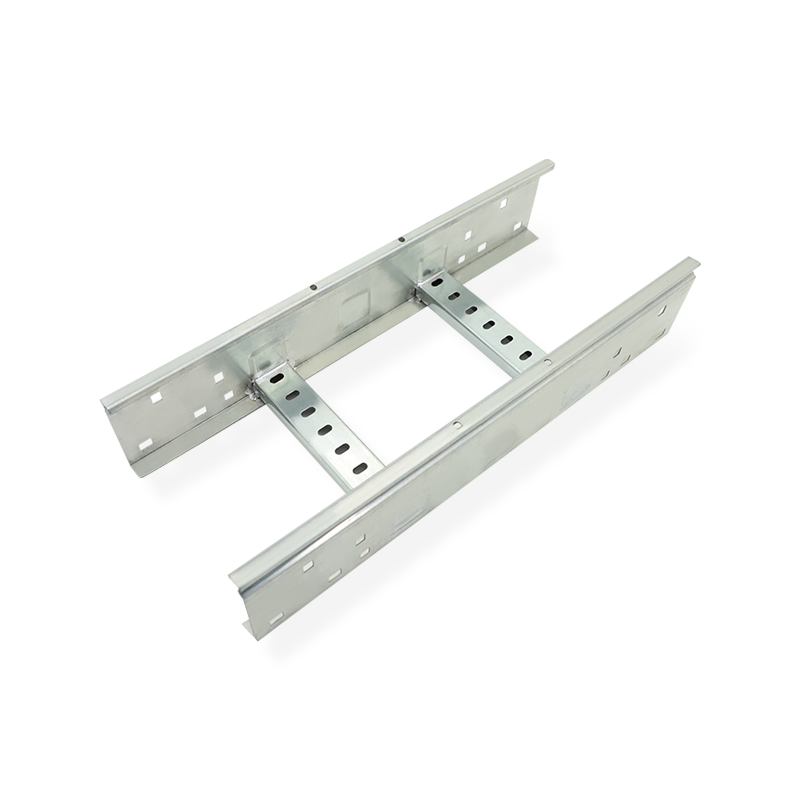

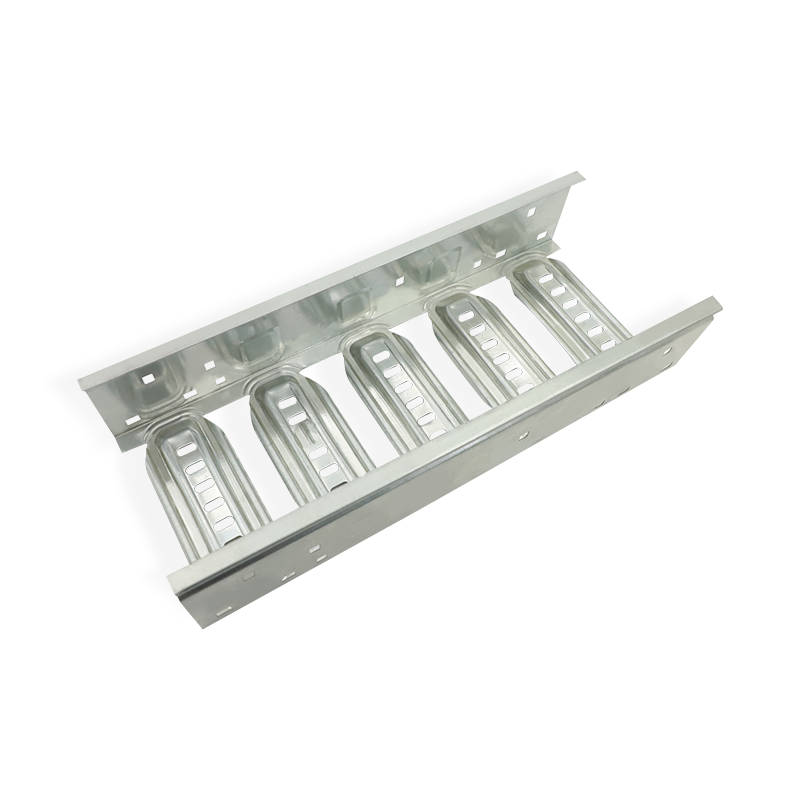

Choosing the correct aluminum alloy cable tray is crucial for both safety and functionality. There are various types available, including ladder trays, trough trays, and channel trays. The type of tray you select will depend on the environment in which it is used, the type of cables being supported, and the required load capacity. Ladder trays are ideal for large bundles of cables, while trough trays are perfect for smaller cable runs that require protection from dust or debris. Channel trays are most suitable for smaller, lighter cable runs.

- Ladder trays: Best for heavy-duty cables in large spaces

- Trough trays: Ideal for protected, smaller cable runs

- Channel trays: Suitable for lighter cables in constrained areas

Essential Tools and Materials for Installation

To properly install aluminum alloy cable trays, certain tools and materials are necessary. This includes measuring instruments, drills, fasteners, and support brackets. It is also important to use high-quality fixing materials to ensure the tray is securely mounted and capable of holding the weight of the cables over time.

- Measuring tape and level

- Drill and mounting hardware

- Support brackets for tray stability

- Cable ties for organizing cables within the tray

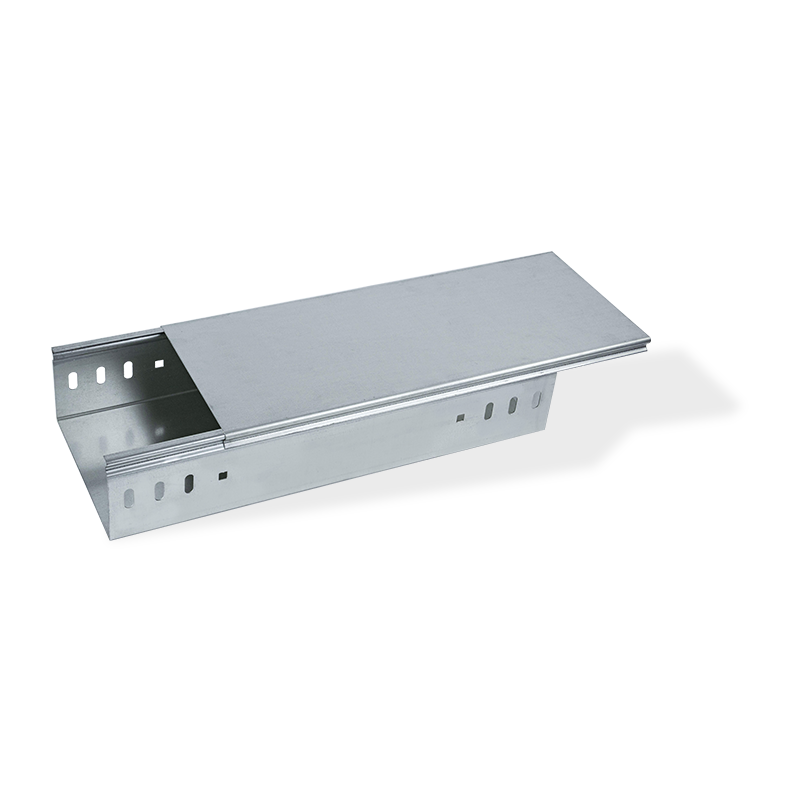

Galvabized steel cable trunking tray with cover

Step-by-Step Installation Process

The installation process for aluminum alloy cable trays can be broken down into simple, manageable steps. Each step is crucial for ensuring the tray is mounted securely and is capable of supporting the cables effectively. Below is a step-by-step guide to help you install aluminum alloy cable trays.

Mounting the Aluminum Alloy Cable Tray

Start by measuring and marking the installation location. It is crucial that the tray is installed at a level height to ensure proper cable management. Once the location is marked, prepare the surface and install the necessary support brackets to secure the tray. Ensure the tray is firmly fastened in place.

- Measure and mark where the tray will be installed

- Install the support brackets and ensure they are level

- Secure the tray with appropriate fasteners

Connecting Multiple Sections of the Tray

If you are installing a tray system that requires multiple sections, it is essential to securely join the trays. Use the correct connectors or joints to ensure the sections are aligned and properly fastened. This will prevent sagging and ensure the tray system remains stable.

- Use tray connectors to join sections

- Ensure alignment and proper attachment

- Check for stability after installation

Installing Cables into the Tray

Once the aluminum alloy cable tray is securely installed, the next step is to lay the cables inside the tray. It is important to organize the cables properly to avoid damage and ensure easy future maintenance. Be sure to leave some slack in the cables to prevent strain.

- Place cables in a systematic manner to avoid tangling

- Use cable ties to bundle and secure cables

- Leave some slack in the cables to reduce strain

Maintenance Tips for Aluminum Alloy Cable Trays

Maintaining your aluminum alloy cable trays is essential to ensuring they last for many years. Regular inspections and cleaning are key to preventing buildup of dust and debris, which can affect the integrity of the tray system. It is also important to check for any signs of damage and address them promptly.

- Inspect trays for damage or wear regularly

- Clean trays to prevent dust buildup

- Check connections and fastenings for stability

Conclusion

Installing aluminum alloy cable trays is a straightforward process that provides long-lasting benefits for electrical systems. By following the correct procedures and using the right materials, you can ensure the tray system is securely installed and maintained. Proper care and maintenance will further extend the lifespan of your aluminum alloy trays, keeping your wiring system efficient and organized for years to come.

FAQ

What are the benefits of using aluminum alloy cable trays?

Aluminum alloy cable trays are preferred due to their corrosion resistance, lightweight nature, and ability to handle both heavy and light electrical cables. They are particularly suitable for industrial environments where durability and long-term performance are essential.

How do I choose the right aluminum alloy cable tray for my project?

Choosing the right tray depends on several factors, including the type of cables being used, the environment (indoor or outdoor), and the weight of the cables. Consider ladder trays for larger cable runs and trough trays for more compact areas.

How often should aluminum alloy cable trays be maintained?

Aluminum alloy cable trays should be inspected regularly, at least once every six months, to check for any signs of wear, damage, or corrosion. Regular cleaning and ensuring that all connections are secure can help extend the tray's lifespan and maintain the overall efficiency of the wiring system.

Can aluminum alloy cable trays be used in outdoor environments?

Yes, aluminum alloy cable trays are highly suitable for outdoor environments due to their corrosion resistance. However, for extreme weather conditions, such as high humidity or exposure to chemicals, it is important to select trays specifically designed for such environments to ensure maximum durability.

Are there any special tools needed to install aluminum alloy cable trays?

Installing aluminum alloy cable trays typically requires basic tools such as measuring tape, a drill, screws, and support brackets. However, depending on the complexity of the installation, you may also need cable ties, connectors, and a level to ensure precise alignment of the trays.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt