If you need any help, please feel free to contact us

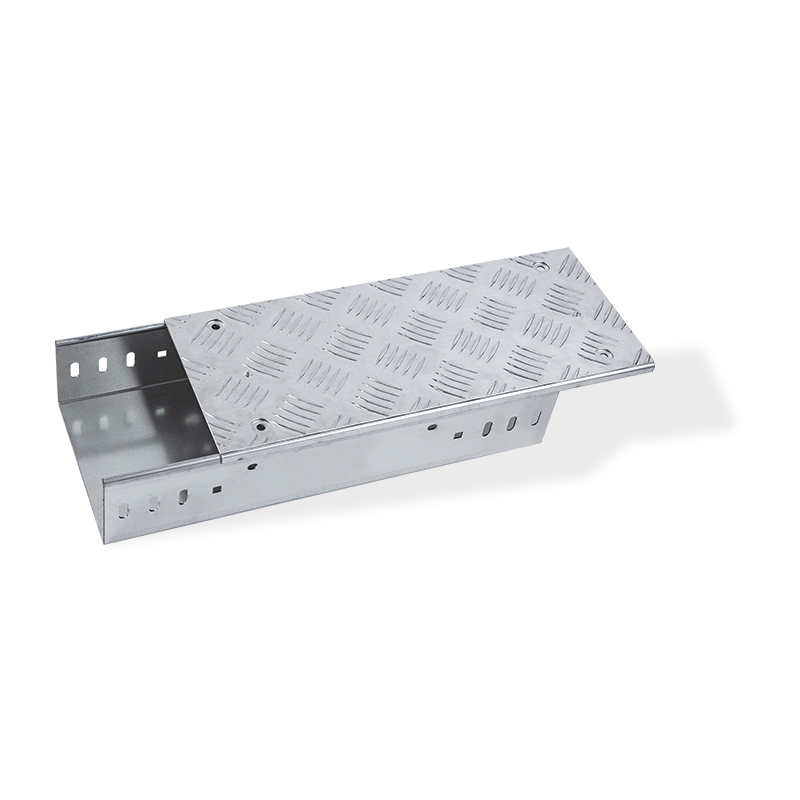

Anti-slip Stainless Steel Cable Tray: The Future of Cable Management

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray?

In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also directly impacts personal and property safety. Among numerous cable management products, the Anti-slip Stainless Steel Cable Tray is becoming the preferred choice for an increasing number of engineering projects due to its unique advantages. The primary reasons for choosing it stem from two core values:

Safety: Eliminating the Risk of Slippage

Traditional cable trays can cause internal cables to slide, accumulate, or even fall due to insufficient friction, especially during vibrations, thermal expansion, or improper installation. The core design of the Anti-slip Stainless Steel Cable Tray involves a unique surface treatment or structural design that increases friction between the cables and the tray. This ensures that cables remain stable under any working conditions, effectively preventing various safety accidents caused by accidental slippage.

Durability: The Advantage of Stainless Steel Material

Choosing stainless steel as the material for the cable tray means you are opting for excellent durability and corrosion resistance. Compared to ordinary carbon steel or galvanized steel, stainless steel offers significant advantages:

Corrosion Resistance Comparison

| Feature | Stainless Steel | Galvanized Steel | Carbon Steel |

| Corrosion Resistance | Excellent, resistant to various chemical corrosions | Good, relies mainly on the zinc layer for protection | Poor, prone to rusting |

| Service Life | Extremely long, can last for decades | Relatively long, but prone to corrosion once the zinc layer wears off | Short, requires frequent maintenance or replacement |

| Maintenance Cost | Extremely low | Medium, requires repair if the zinc layer is damaged | Extremely high, requires regular anti-rust treatment |

| Application Environment | Suitable for harsh environments such as humid, salty, and chemically corrosive conditions | Suitable for general indoor and outdoor environments | Only suitable for dry, non-corrosive environments |

Anti-slip Stainless Steel Cable Trough: A Dual Guarantee of Safety and Durability

In complex industrial and commercial environments, cable management is a systemic project concerning safety and long-term benefits. In this field, the Anti-slip Stainless Steel Cable Tray provides an unparalleled dual guarantee of safety and durability with its core feature of "anti-slip stainless steel cable trough."

1. Safety: The Crucial Role of Anti-slip Trough

The sliding of cables within the tray, while seemingly minor, hides huge safety hazards. The anti-slip stainless steel cable trough design is precisely aimed at solving these problems. By using special embossing, grooves, or bumps on the bottom or sides of the tray, it significantly increases the friction between the cables and the tray, keeping the cables firmly in place. This design is particularly suitable for installations that are vertical or on slopes, fundamentally eliminating all potential risks caused by cable slippage.

2. Durability: The Advantage of Stainless Steel Material

Choosing stainless steel as the trough material is key to ensuring its long-term stable operation. Compared to other materials, stainless steel has significant advantages in durability:

Material Performance Comparison

| Feature | Stainless Steel | Hot-dip Galvanized Steel | Aluminum Alloy |

| Corrosion Resistance | Excellent, suitable for most environments | Good, but performs poorly in highly corrosive environments | Good, but susceptible to corrosion in specific alkaline environments |

| Mechanical Strength | Excellent, strong load-bearing capacity | Good, but its bending strength is inferior to stainless steel | Good, but relatively low load-bearing capacity |

| High-temperature Resistance | Excellent, remains stable in high-temperature environments | Fair, high temperatures may affect coating adhesion | Poor, easily deforms under high temperatures |

| Aesthetics | Smooth surface, easy to clean, does not discolor easily | Surface has zinc spangles, may darken over time | Surface can oxidize, difficult to maintain gloss |

| Maintenance Cost | Extremely low, requires almost no maintenance | Medium, requires maintenance if the zinc layer is damaged | Medium, surface treatment may require maintenance |

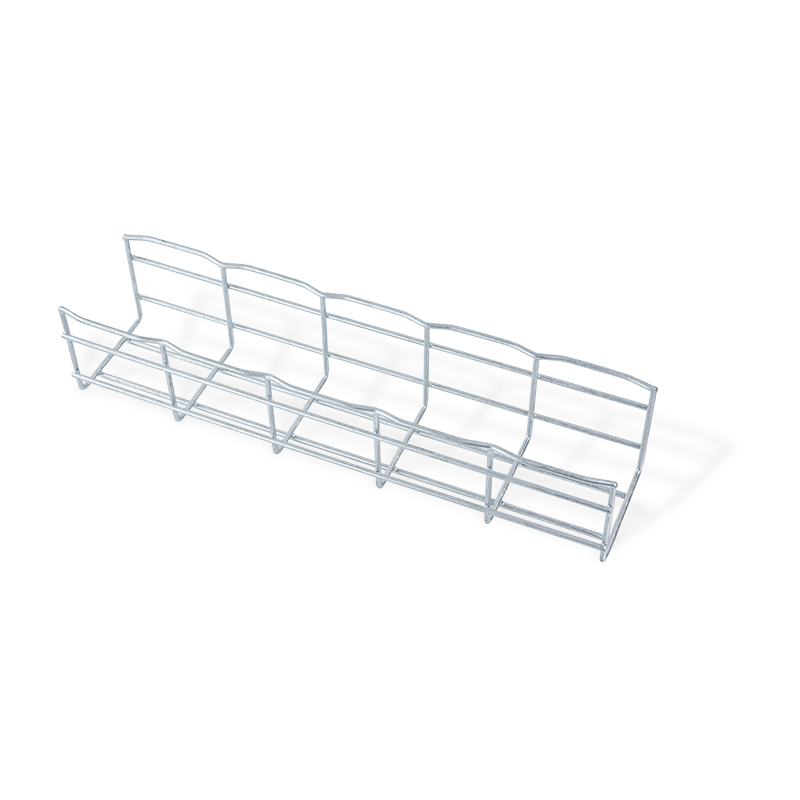

Anti-slip Stainless Steel Cable Tray: Solutions for Different Application Scenarios

The core advantage of the Anti-slip Stainless Steel Cable Tray is its versatility and adaptability. With its **anti-slip stainless steel cable tray** feature, these products can provide safe and reliable cable management solutions for various complex and demanding environments.

1. Industry and Infrastructure: A Sturdy Guardian in Extreme Environments

In industrial fields such as petrochemicals, power plants, tunnels, and transportation hubs, cables face extreme conditions like high temperatures, humidity, chemical corrosion, and high-frequency vibrations. The **stainless steel** material's corrosion resistance ensures the tray will not fail due to environmental erosion, while the **anti-slip** function prevents cables from slipping due to equipment vibration, ensuring the continuous and stable operation of power and control systems.

2. Commerce and Architecture: The Perfect Combination of Aesthetics, Efficiency, and Safety

In modern commercial buildings, data centers, and medical facilities, the demand for cable management is increasing. Adopting the **anti-slip perforated stainless steel tray** design can effectively improve heat dissipation efficiency. At the same time, the **anti-slip** function ensures that a vast number of cables do not become misaligned during routine maintenance or expansion, avoiding signal interference or faults caused by cable disorganization.

3. Parameter Comparison: Selecting Tray Types for Different Applications

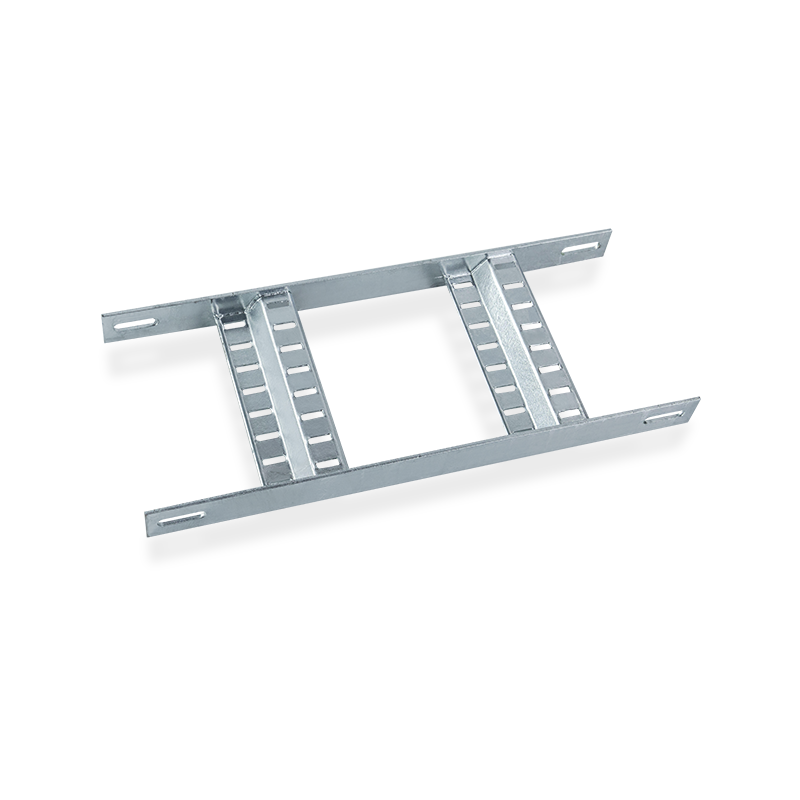

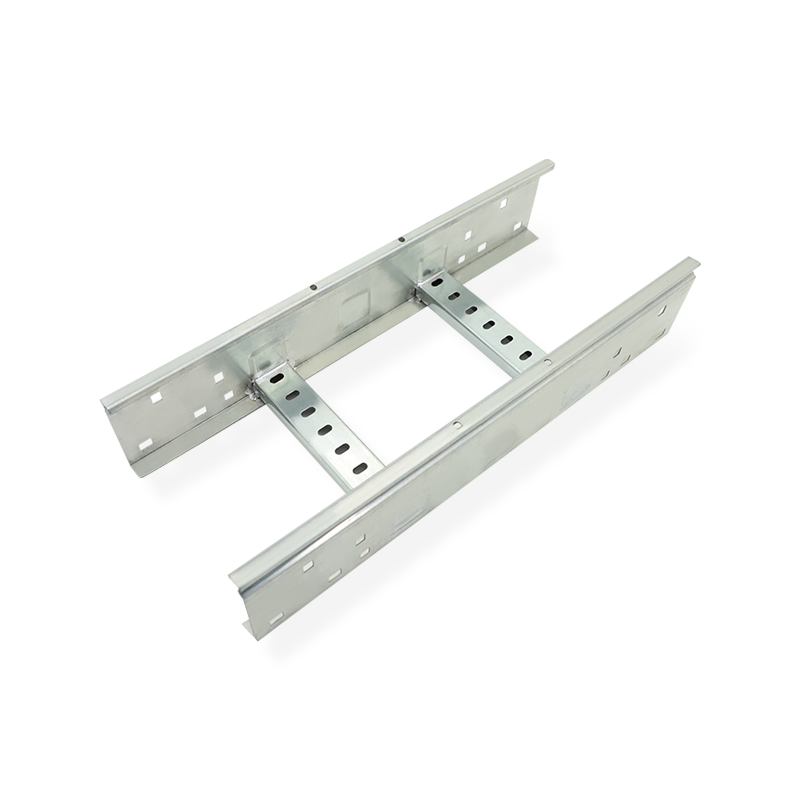

| Tray Type | Anti-slip Ladder Type | Anti-slip Trough Type | Anti-slip Perforated Type |

| Structure | Composed of side rails and rungs, open type | Enclosed, box-like | Bottom with perforations, open type |

| Main Function | High load-bearing, good for heat dissipation and inspection | Protects cables from external interference | Combines load-bearing, heat dissipation, and protection |

| Typical Applications | Large power cables, high-voltage cables | Sensitive signal cables, communication cables | Data centers, commercial buildings, industrial facilities |

| Advantages | Strong load-bearing capacity, excellent heat dissipation, easy to install | Provides comprehensive protection for cables, prevents dust ingress | Good heat dissipation, lightweight, suitable for dense cables |

| Disadvantages | Provides less protection for cables | Poor heat dissipation, inconvenient for inspection | Slightly lower load-bearing capacity than ladder type |

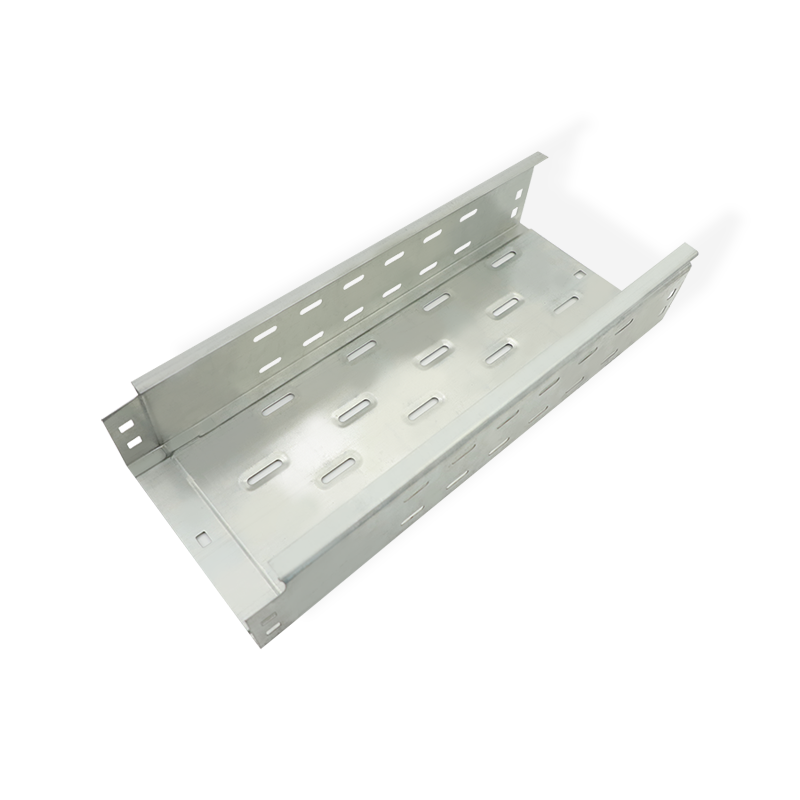

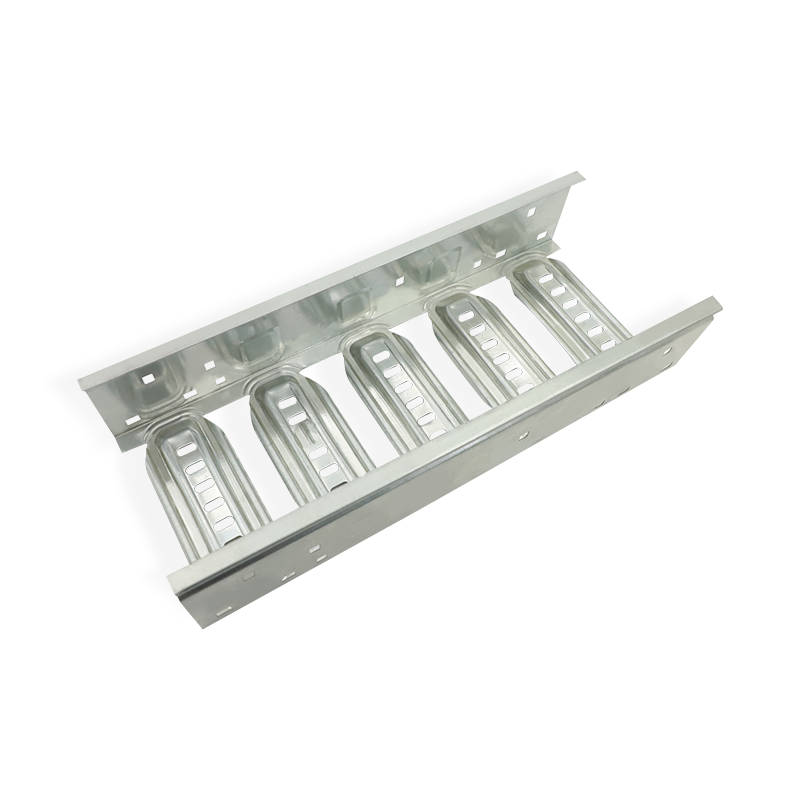

Anti-slip Perforated Stainless Steel Tray: Balancing Heat Dissipation and Load-bearing

In modern cable management systems, efficient heat dissipation and reliable load-bearing capacity are two key factors for ensuring stable system operation. The Anti-slip Perforated Stainless Steel Tray perfectly combines these two functions, making it an ideal choice for high-density cable environments.

1. Functionality of the Perforated Design: Optimizing Heat Dissipation and Maintenance

The core advantage of the **perforated tray** lies in its dense perforated design on the bottom. These holes are not only for reducing the tray's own weight but, more importantly, provide a vital ventilation channel for the cables. This design allows for free air circulation, greatly improving heat dissipation efficiency and effectively extending the service life of the cables.

2. The Balance of Anti-slip and Load-bearing: A Stable and Reliable System Guarantee

The anti-slip function of the anti-slip stainless steel cable tray is equally crucial for perforated trays. Despite a reduced surface area, special surface treatments or perforated edge designs ensure that cables are held firmly in place within the tray. At the same time, a high-quality **anti-slip perforated stainless steel tray** is designed with specific structural and material thickness to meet stringent load-bearing requirements while maintaining its anti-slip properties.

Parameter Comparison of Different Load-bearing Levels

| Parameter | Light-duty Perforated Tray | Medium-duty Perforated Tray | Heavy-duty Perforated Tray |

| Material Thickness | 0.8mm - 1.2mm | 1.2mm - 2.0mm | Above 2.0mm |

| Maximum Load Capacity | Suitable for light control cables and fiber optics | Suitable for medium-density power and control cables | Suitable for high-density, large-diameter heavy cables |

| Typical Span | 1.5m - 2.0m | 2.0m - 3.0m | Above 3.0m |

| Main Applications | Office buildings, small labs | Commercial buildings, data centers, factory workshops | Power plants, large industrial plants, tunnels |

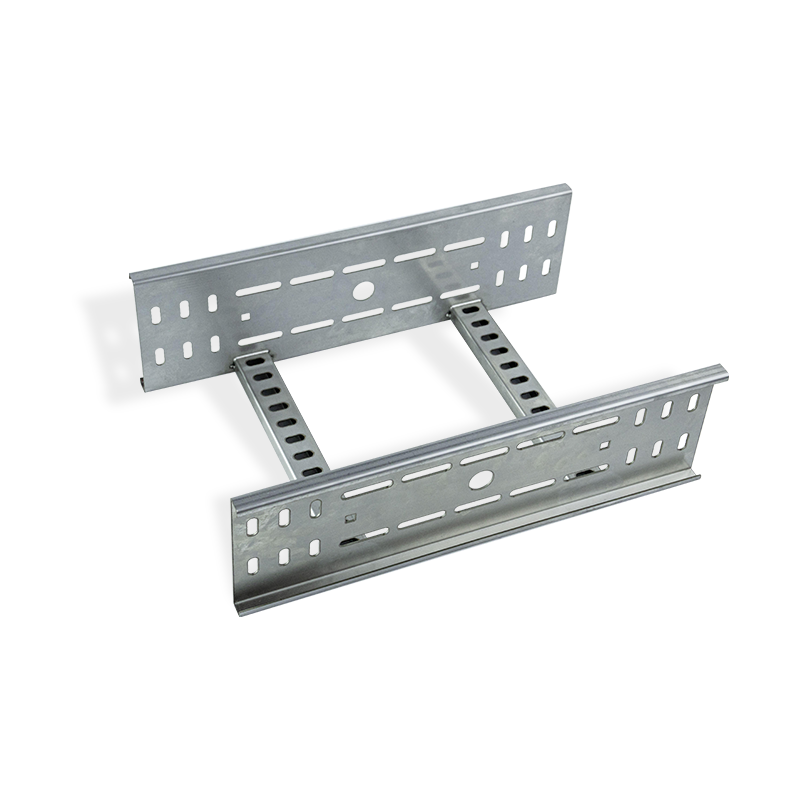

Anti-slip Tray Stainless Steel: As a Core Component of Cable Management Systems

A cable management system is a complex network of various components. In this system, the Anti-slip Tray Stainless Steel is not merely a simple support but a core component, and its selection directly determines the stability and reliability of the entire system.

1. Systemic Perspective: The Synergy of Trays and Accessories

A complete cable management system includes multiple components that work together. The Anti-slip Tray Stainless Steel acts as the main trunk, working in concert with various accessories. The anti-slip function of the anti-slip stainless steel cable tray ensures that cables remain stable at any bend, corner, or inclined position, preventing slippage caused by uneven connections between accessories.

2. Future Trends: Intelligence and Standardization

With the development of Industry 4.0 and the Internet of Things (IoT), future cable management systems will become more intelligent. The combination of an anti-slip stainless steel tray with smart monitoring technology can enable real-time monitoring of cable temperature, load, and faults. Furthermore, standardization is key to ensuring engineering quality and interoperability.

3. Parameter Comparison: Load-bearing and Function of Different System Components

| Component Name | Anti-slip Tray Stainless Steel | Elbows/Connectors | Supports/Hangers |

| Main Function | Primary load-bearing and routing | Changing direction, connection | Fixing, load-bearing, installation |

| Load-bearing Capacity | Core load-bearing, determines the overall system capacity | Must match the tray to ensure stability at connections | Determines the tray's support span and stability |

| Material Requirements | Corrosion-resistant, high strength, anti-slip | Same material as the tray to ensure consistency | High strength, corrosion-resistant, ensures long-term stability |

| Installation Features | Modular design, easy to assemble | Adjustable, adapts to different angles | Adjustable height and position, adapts to site conditions |

Why Anti-slip Stainless Steel Cable Tray is the Best Choice

Among many cable management products, the Anti-slip Stainless Steel Cable Tray is not just an ordinary option but the best choice for current and future cable management systems. Its advantage lies in the perfect integration of safety, durability, and functionality, providing your project with unparalleled comprehensive value.

1. Comprehensive Advantages: A Triad of Safety, Durability, and Functionality

The unique feature of the Anti-slip Stainless Steel Cable Tray is that it addresses the shortcomings of traditional cable trays in single functions, combining multiple advantages in one: ultimate **safety**, outstanding **durability**, and powerful **functionality**.

2. Value Comparison: The Optimal Choice Based on Comprehensive Consideration

| Evaluation Dimension | Anti-slip Stainless Steel Cable Tray | Ordinary Carbon Steel/Galvanized Tray |

| Initial Cost | Higher | Lower |

| Long-term Maintenance Cost | Extremely low, almost no maintenance needed | Extremely high, requires regular anti-corrosion treatment, inspection, and replacement |

| Safety Risks | Extremely low, effectively prevents cable slippage and accidents | Higher, risks of cable slippage, insulation wear, etc. |

| Service Life | Extremely long, can last for decades | Shorter, prone to rust and corrosion from environmental factors |

| Environmental Adaptability | Excellent, suitable for all kinds of harsh environments | Poor, not suitable for humid, corrosive environments |

| Overall Value | Highest, low risk, low maintenance, high reliability | Lower, with potential safety hazards and high long-term costs |

Frequently Asked Questions (FAQ)

Q1: Why choose an anti-slip stainless steel cable tray? What is the difference between it and trays made of ordinary materials?

A1: Choosing an anti-slip stainless steel cable tray (Anti-slip Stainless Steel Cable Tray) is primarily for greater safety and a longer service life. Compared to ordinary carbon steel or galvanized trays, it effectively prevents safety accidents caused by cable slippage due to vibrations or gravity. Additionally, the stainless steel material has excellent corrosion resistance, capable of withstanding harsh environments, thus significantly reducing long-term maintenance costs. As a professional enterprise in the cable tray field, **Jiangsu Youming Group Co., Ltd.** specializes in the research and development and production of high-quality cable trays. Its product series covers various materials such as stainless steel, hot-dip galvanized steel, and aluminum alloy, with various specifications like ladder, trough, and perforated types, ensuring safety and reliability for any project.

Q2: What quality assurance does the anti-slip stainless steel cable tray from Jiangsu Youming Group Co., Ltd. offer?

A2: **Jiangsu Youming Group Co., Ltd.** is an innovative high-tech enterprise specializing in the R&D and production of cable trays. The company boasts fully automated production lines, including longitudinal and transverse shearing, automatic forming, automatic welding, laser cutting, and CNC turret punching. For quality assurance, the company has established an independent testing center that conducts strict quality inspections on every step, from raw material procurement to product delivery, ensuring that product quality reaches the highest level in the industry. The anti-slip stainless steel cable trays it produces have won the trust and recognition of many well-known enterprises for their stable and reliable performance.

Q3: Besides the anti-slip function, what other advantages do the cable trays from Jiangsu Youming Group Co., Ltd. have?

A3: **Jiangsu Youming Group Co., Ltd.** was established in 2015 with a registered capital of 50 million RMB, covering an area of 60 acres and a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays. The company not only focuses on core functions like anti-slip and corrosion resistance but also strives to provide comprehensive solutions. Its rich product variety includes stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof series, as well as various specifications and models. The products are widely used in infrastructure, transportation, communication, power, and many other fields. With years of market expansion, the company can provide customers with comprehensive product selection services, ensuring that each project receives the most suitable cable management solution, thus achieving the optimal balance between efficiency and cost.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt