If you need any help, please feel free to contact us

The Ultimate Guide to Marine Cable Ladder Tray Systems

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. This comprehensive guide delves into the specifics of Marine Cable Ladder Tray systems, exploring their advantages, applications, and key selection criteria to ensure optimal performance in corrosive environments.

In-Depth Analysis of Marine Cable Ladder Trays

Understanding Marine Cable Ladder Tray Systems

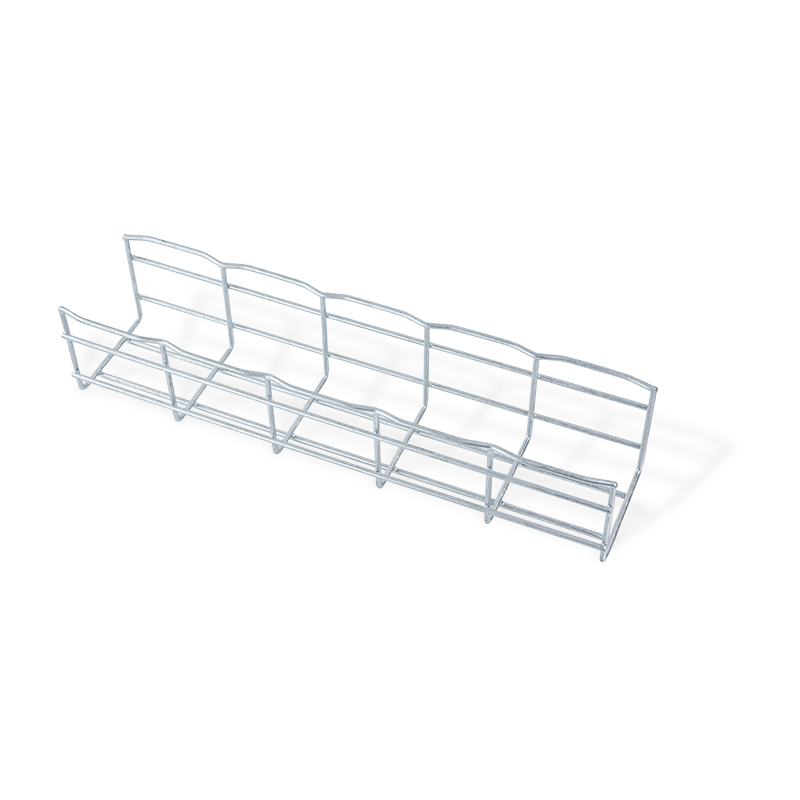

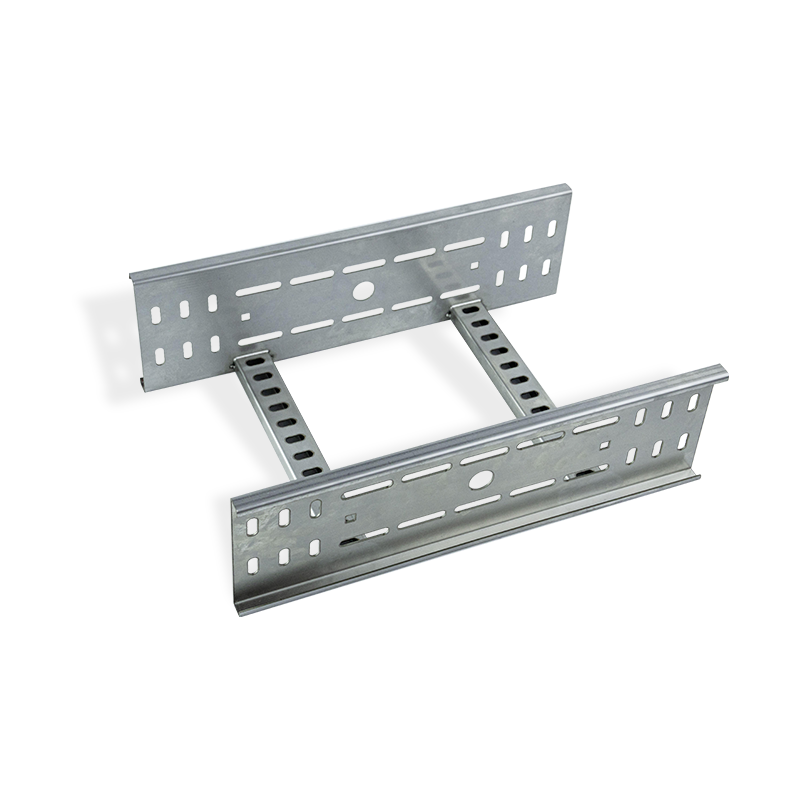

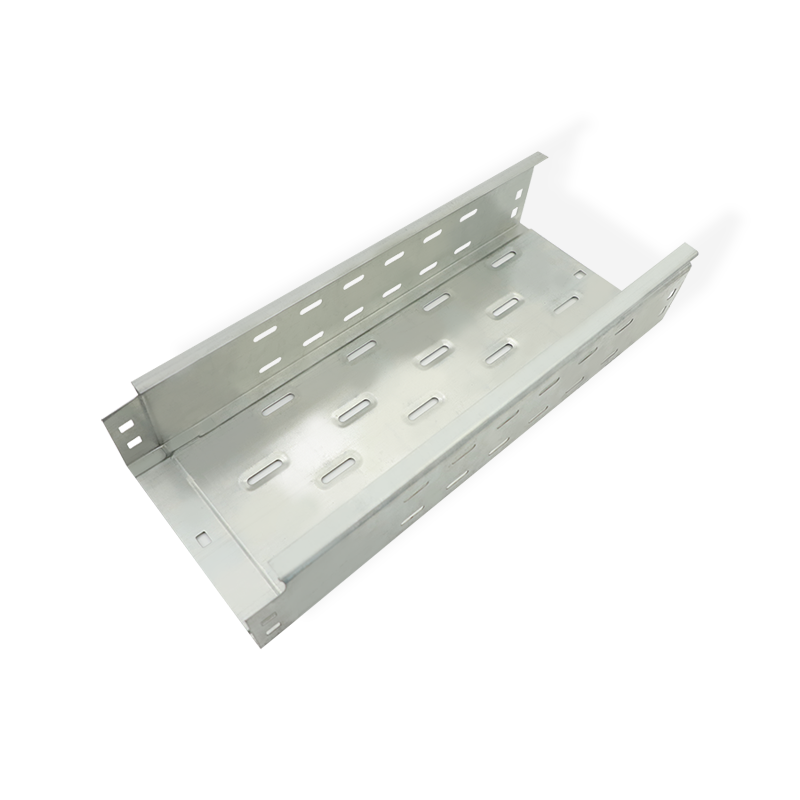

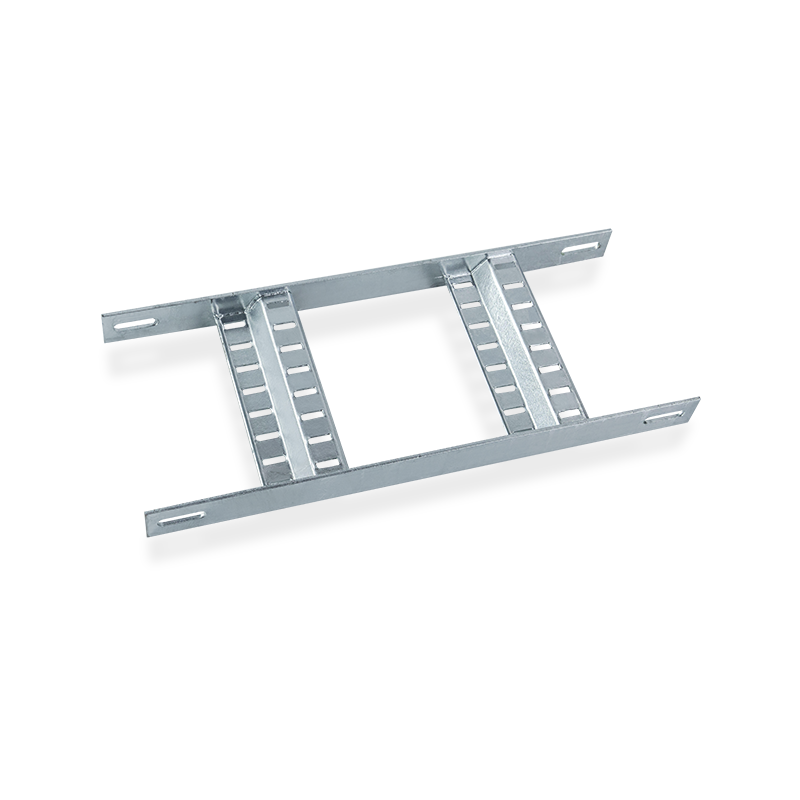

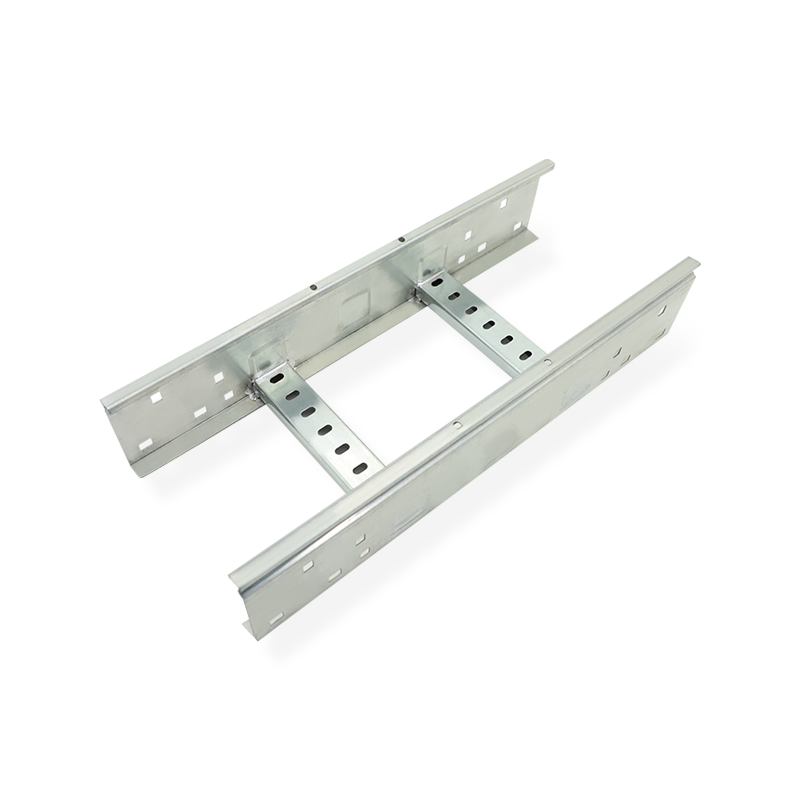

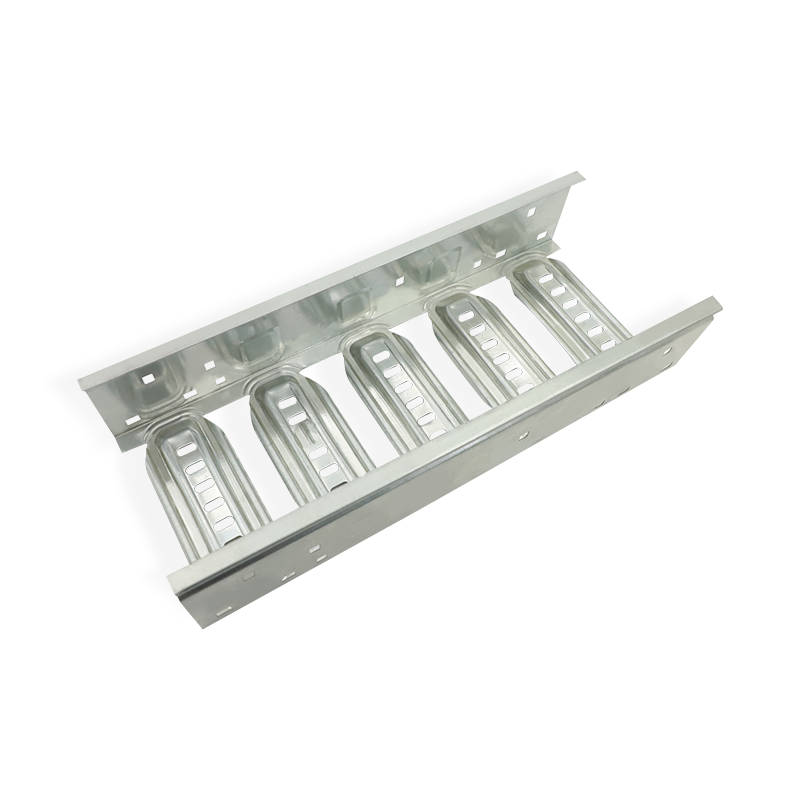

A Marine Cable Ladder Tray is a rigid structural system used to support heavy cables and pipes in marine environments. Its open rung design offers superior durability and ventilation compared to solid-bottom trays.

Key Characteristics:

- Constructed from high-grade, corrosion-resistant materials.

- Features a robust ladder-like design for maximum strength.

- Designed to meet stringent international marine standards.

marine cable ladder tray specifications and load capacity

Understanding the specifications is paramount for system integrity. Load capacity is the most critical specification, determining the weight the tray can safely support.

Primary Specifications:

- Rung spacing and depth.

- Side rail height and thickness.

- Material grade and finish type.

Comparing load capacity definitions helps in selecting the right tray. The Uniform Load capacity is the maximum distributed load the tray can support over its entire span, while the Concentrated Load is the maximum point load it can bear at the center of the span.

| Load Type | Definition | Importance |

| Uniform Load | The maximum distributed load the tray can support over its entire span. | Crucial for planning cable runs with consistent weight distribution. |

| Concentrated Load | The maximum point load the tray can bear at the center of the span. | Essential for accounting for heavy individual cables or connection points. |

Material Showdown: galvanized steel vs aluminum marine cable tray

The choice of material directly impacts performance, weight, and cost. The two most common materials are hot-dip galvanized steel and marine-grade aluminum.

Galvanized steel offers exceptional strength and durability, making it ideal for high-load applications. Aluminum provides a superior strength-to-weight ratio and inherent corrosion resistance, which is beneficial for reducing overall weight on a vessel.

| Material | Galvanized Steel | Marine Aluminum |

| Corrosion Resistance | Excellent (with coating) | Superior (inherent) |

| Weight | Heavier | Lighter |

| Strength | Very High | High (Good Ratio) |

| Ideal Use Case | High-load, harsh environments | Weight-sensitive applications |

Ensuring Longevity with a corrosion resistant cable tray for offshore platforms

Offshore platforms represent one of the most aggressive environments for any material. A corrosion resistant cable tray for offshore platforms is not a luxury but a necessity.

Corrosion Protection Methods:

- Hot-Dip Galvanizing: A thick zinc coating provides sacrificial protection.

- Stainless Steel: Grades like 316L offer excellent resistance to saltwater pitting.

- Powder Coating: An additional layer of protection for aesthetics and extra resilience.

Safety First: fire retardant cable management systems for vessels

Fire safety is a top priority on any vessel. Cable trays play a indirect but vital role in a fire retardant cable management systems for vessels.

Fire Safety Contributions:

- Prevents cable sagging that could expose cables to damage and short circuits.

- Its open design avoids heat buildup, a potential fire hazard.

- Can be specified with materials and coatings that are non-combustible and prevent the spread of flames.

A Guide on how to install marine cable ladder tray on ship

Proper installation is as important as the product itself. A guide on how to install marine cable ladder tray on ship ensures system reliability.

Installation Best Practices:

- Planning and Measurement: Pre-plan the entire run, avoiding interference with other systems.

- Support Spacing: Adhere strictly to the manufacturer's recommended support spacing based on the load capacity.

- Grounding and Bonding: Ensure the entire tray system is properly grounded to prevent electrostatic discharge.

- Expansion Joints: Incorporate expansion joints to accommodate thermal expansion and contraction of the ship's hull.

Conclusion

Selecting and implementing the right Marine Cable Ladder Tray system is a foundational aspect of marine electrical engineering. By focusing on precise marine cable ladder tray specifications and load capacity, choosing between materials like galvanized steel vs aluminum marine cable tray, prioritizing a corrosion resistant cable tray for offshore platforms, integrating fire retardant cable management systems for vessels, and following proper procedures on how to install marine cable ladder tray on ship, engineers can ensure a safe, reliable, and durable cable management solution that stands the test of time and the harshness of the sea.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt