If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

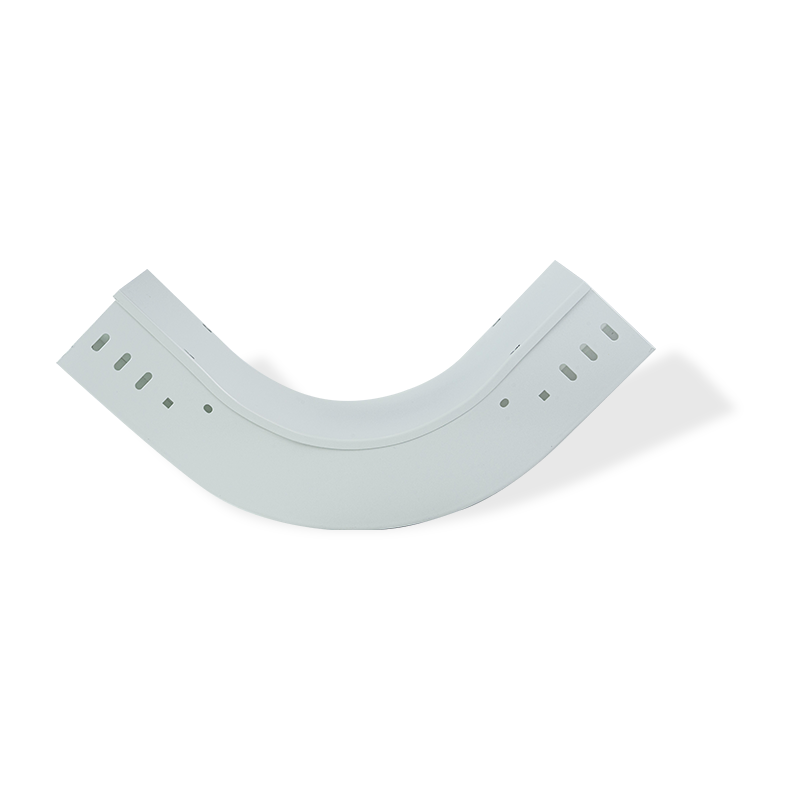

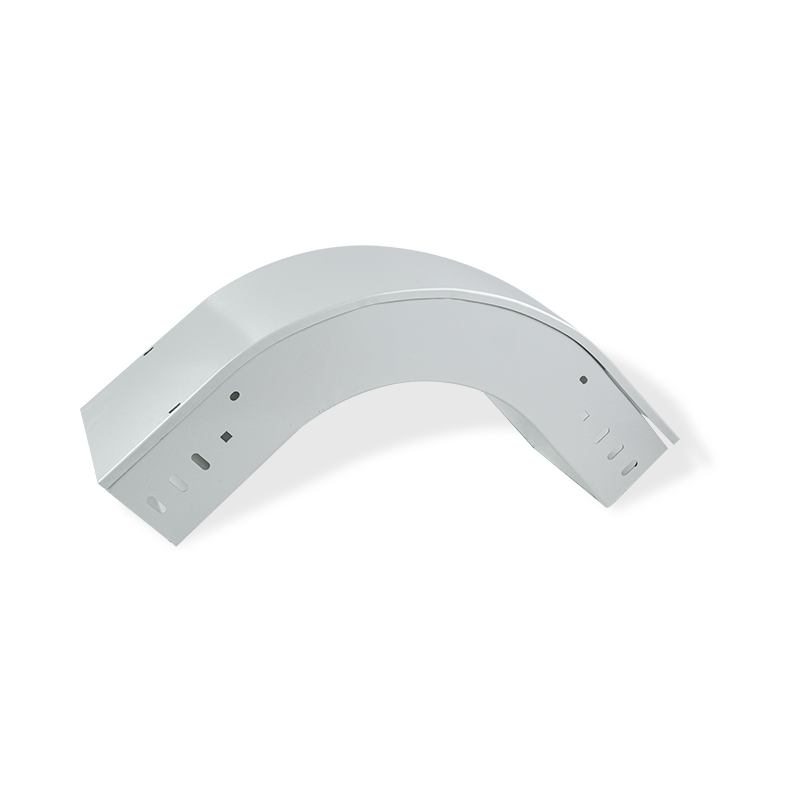

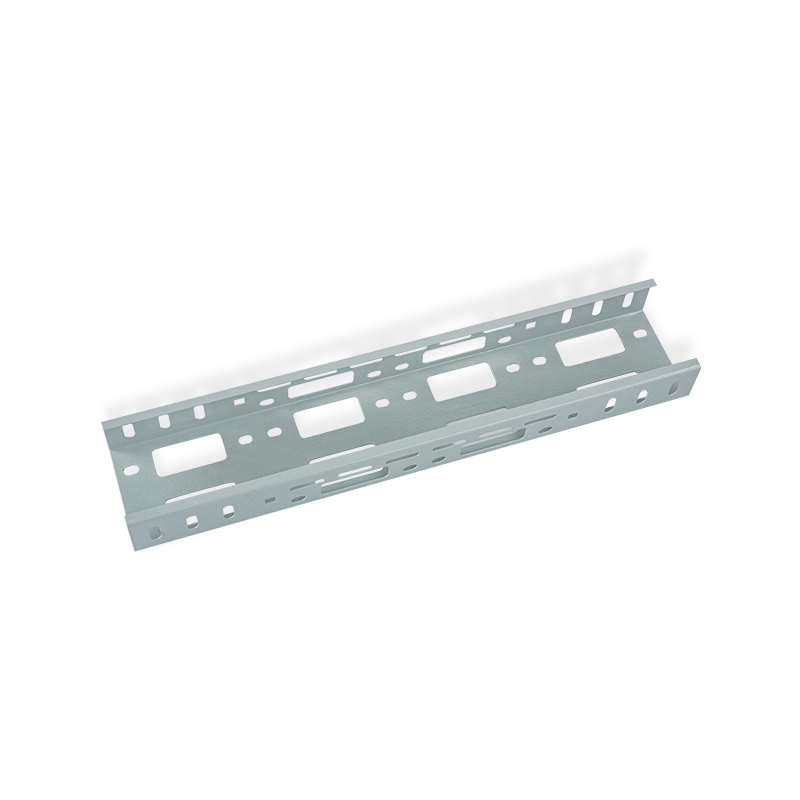

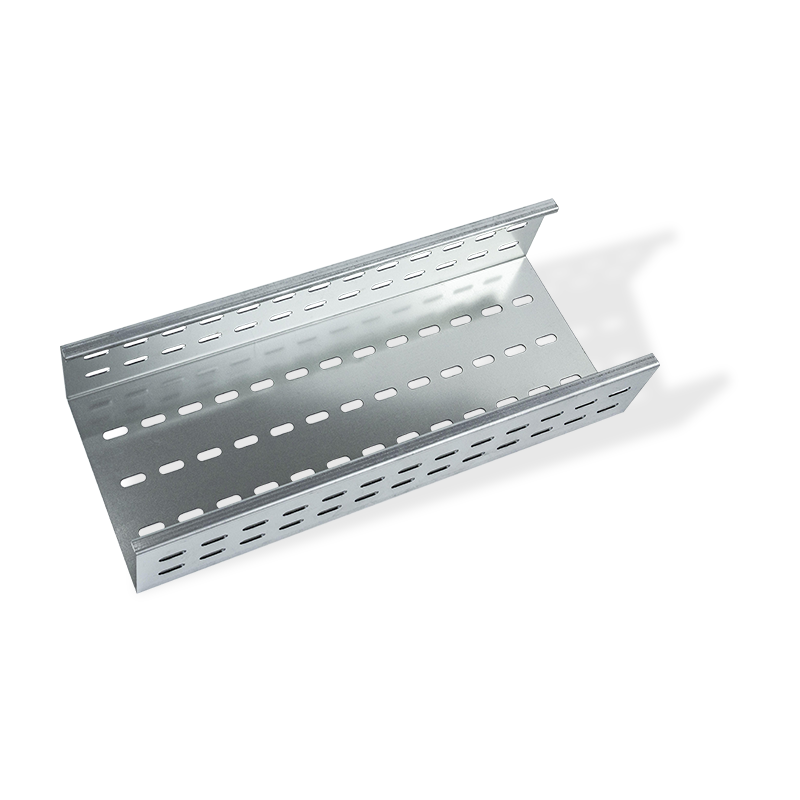

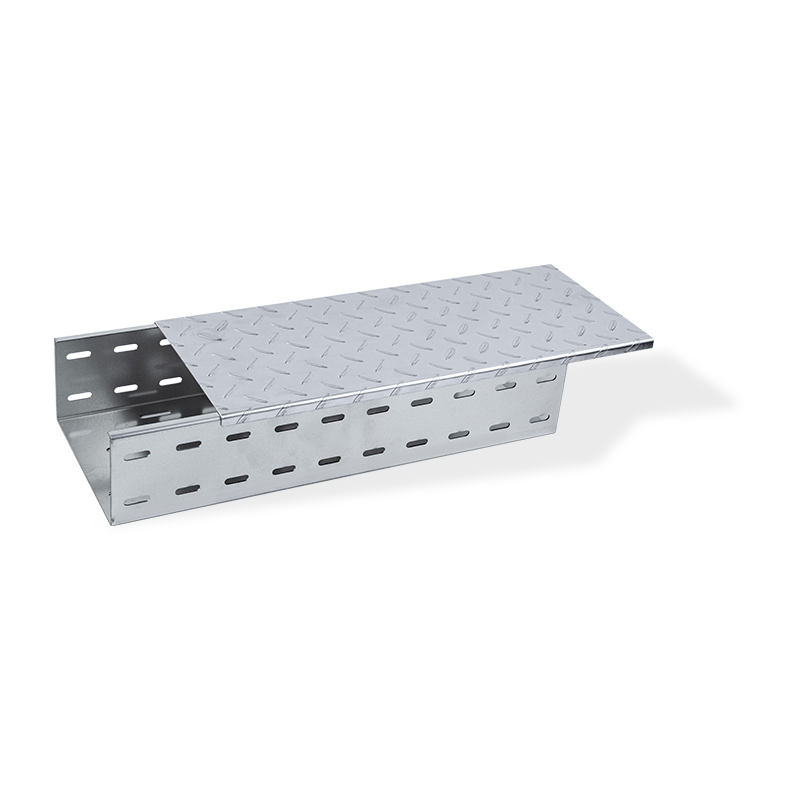

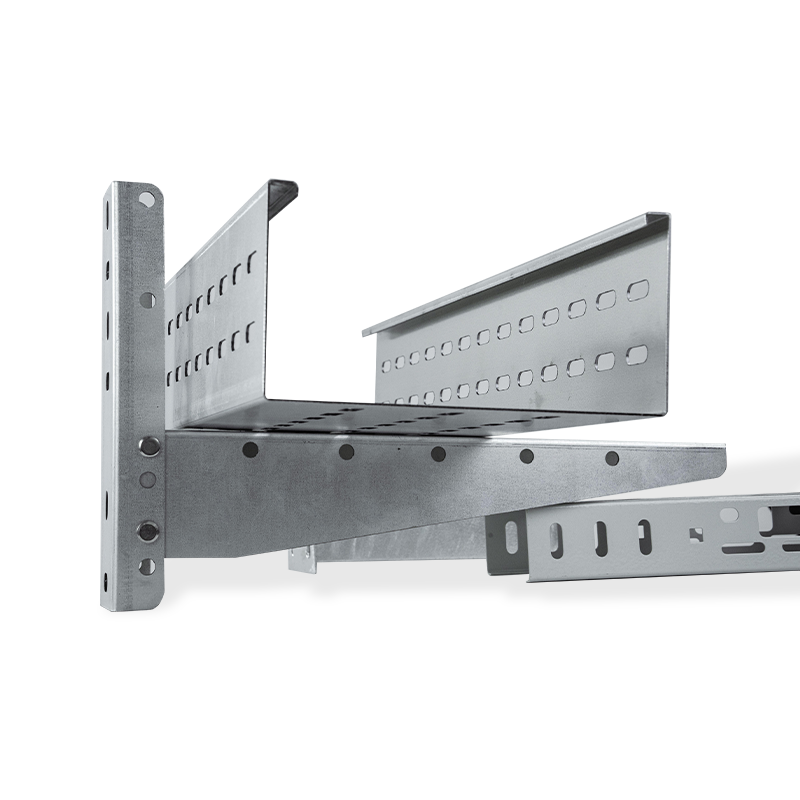

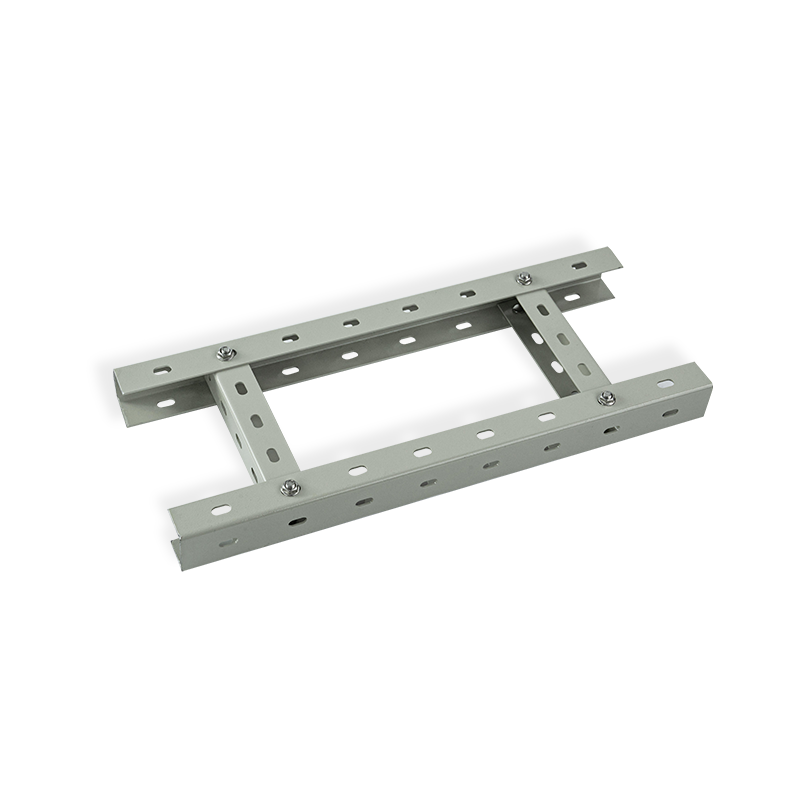

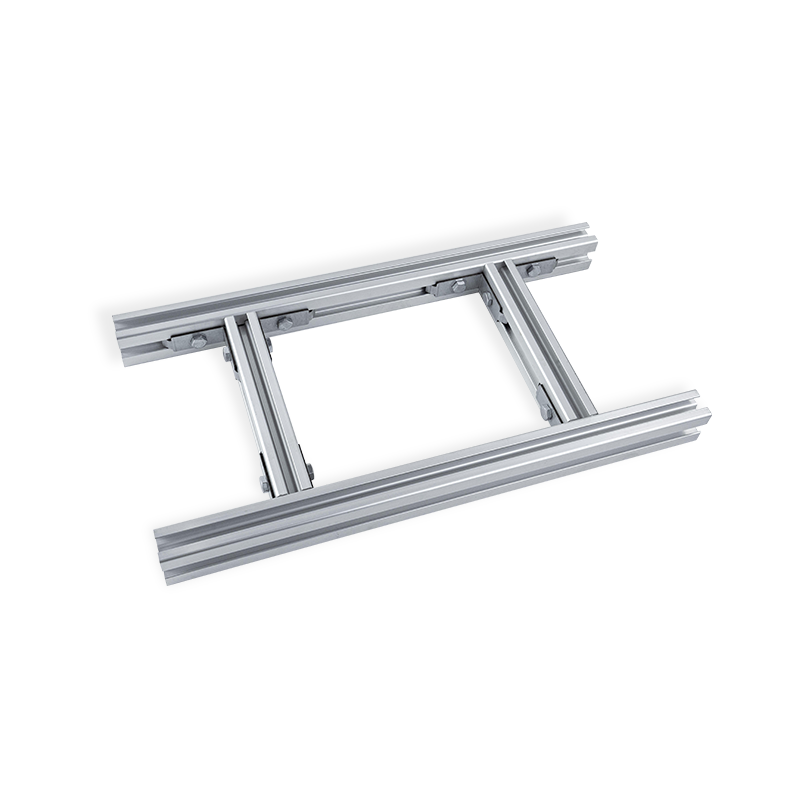

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Choosing the right cable management system is crucial for the safety and efficiency of any electrical installation. While there are many options available, the punched perforated cable tray stands out for its unique bene...

In modern buildings and industrial facilities, the safety, efficiency, and reliability of wiring systems are paramount. The stainless steel wire tray, with its excellent material properties and flexible design, has becom...

In the world of industrial cable tray manufacturing, precision and reliability are non-negotiable. At Youming group, we believe these standards are achieved not just through advanced machinery, but through the unbreakab...

How to choose galvanized cable tray? Thickness, load and standard specification guide

Galvanized cable tray is a key infrastructure in the power, communication, construction and other industries. Its anti-corrosion performance, load-bearing capacity and installation specifications directly affect the safety and service life of the project.

1. Selection of galvanizing process: anti-corrosion performance is the key

Galvanized cable trays are mainly anti-corrosion through hot-dip galvanizing (HDG) and electrogalvanizing (EG) processes. The application scenarios of the two are significantly different:

Hot-dip galvanizing (HDG)

The zinc layer thickness is usually between 45-100μm. The metallurgical bonding layer is formed by high-temperature zinc immersion. The anti-corrosion life can reach 20-50 years. It is suitable for high-corrosion environments such as outdoor, chemical plants, and coastal areas. The international standard is mainly ASTM A123, which is more expensive but has better long-term cost performance.

Electrogalvanizing (EG)

The zinc layer thickness is only 5-15μm. The zinc layer is attached by electrolysis process. The anti-corrosion ability is weak (5-10 years), but the cost is low and the surface is smoother. It is suitable for dry indoor environments (such as weak current systems in office buildings) and must comply with ASTM B633 standards.

Selection principles:

Hot-dip galvanizing must be selected for humid, acidic and alkaline environments;

When short-term projects or budgets are limited, electrogalvanizing can be used in non-critical areas.

2. Bridge thickness and load capacity: core parameters of safety

The steel plate thickness of the bridge directly determines its mechanical strength and load-bearing capacity, which needs to be comprehensively evaluated based on the cable weight and installation method (suspended/bracket):

(1) Thickness classification reference

Light (C1): side plate 0.8-1.2mm, bottom plate 0.8-1.0mm, suitable for light load scenarios such as communication cables.

Medium (C2): side plate 1.2-1.5mm, bottom plate 1.0-1.2mm, suitable for ordinary power cables in commercial buildings.

Heavy duty (C3): side plate 1.5-2.0mm, bottom plate 1.2-1.5mm, used in densely laid environments such as industrial plants and substations.

Ultra-heavy duty (C4): side plate ≥2.0mm, bottom plate ≥1.5mm, specially designed for data centers and heavy machinery.

(2) Load matching recommendations

Light bridge static load ≤50kg/m, limited to weak current systems;

Medium bridge load 50-100kg/m, can cover most low-voltage cable needs;

Heavy bridge load 100-200kg/m, suitable for high-voltage cable or long span (>3m) installation;

Ultra-heavy bridge load ≥200kg/m, needs to be used with reinforced crossbars.

Key tips:

When actually selecting, the total cable weight should not exceed 80% of the bridge nominal load;

In suspended installation or vibration environment, one thickness grade needs to be increased.

3. International standards and compliance requirements

Different regions have clear requirements for the technical specifications of galvanized bridges. When selecting, you need to focus on the following standards:

North American market: follow the NEMA VE-1 standard, emphasizing the thickness of the galvanized layer and fire resistance (UL certification required);

Internationally used: IEC 61537 specifies test methods such as structural strength and grounding continuity;

Chinese market: GB/T 21762 is equivalent to the IEC standard, and additionally requires load classification identification;

European market: BS EN 10346 specifies that the zinc layer of the hot-dip galvanizing process is ≥45μm.

Compliance points:

The hot-dip galvanized layer must pass the salt spray test (such as ISO 9227);

Fire protection scenarios require flame retardant certification (such as UL 1565).

4. Special environment adaptation solution

High corrosion environment: hot-dip galvanized bridge + epoxy resin coating, or stainless steel;

High temperature area (such as steel mill): choose thickened type (≥2.0mm) or heat-resistant coating;

Electromagnetic shielding requirements: use non-magnetic galvanized bridge and ensure the integrity of the grounding system.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt