If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

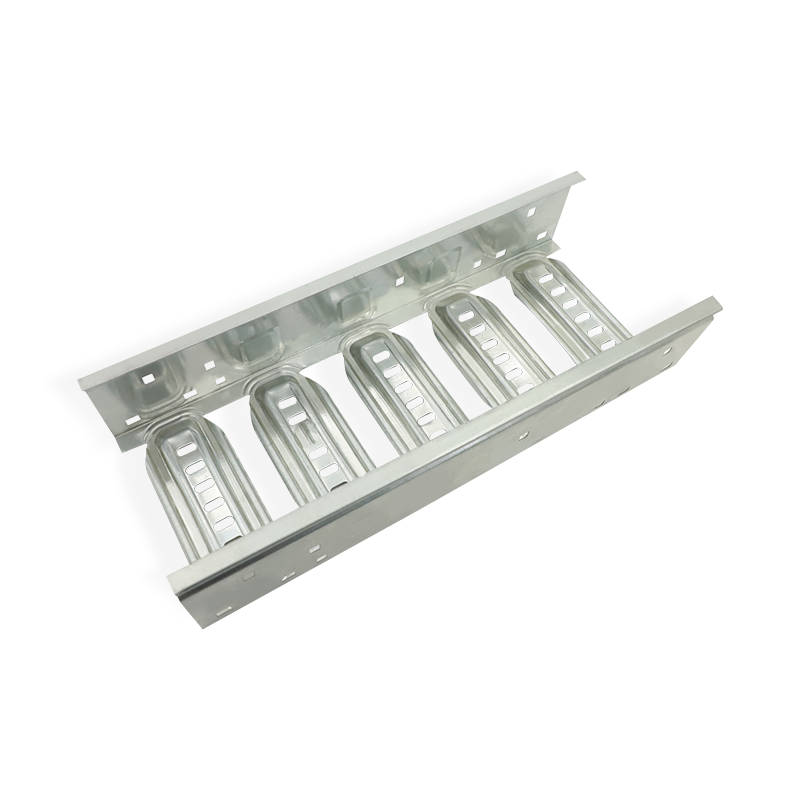

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

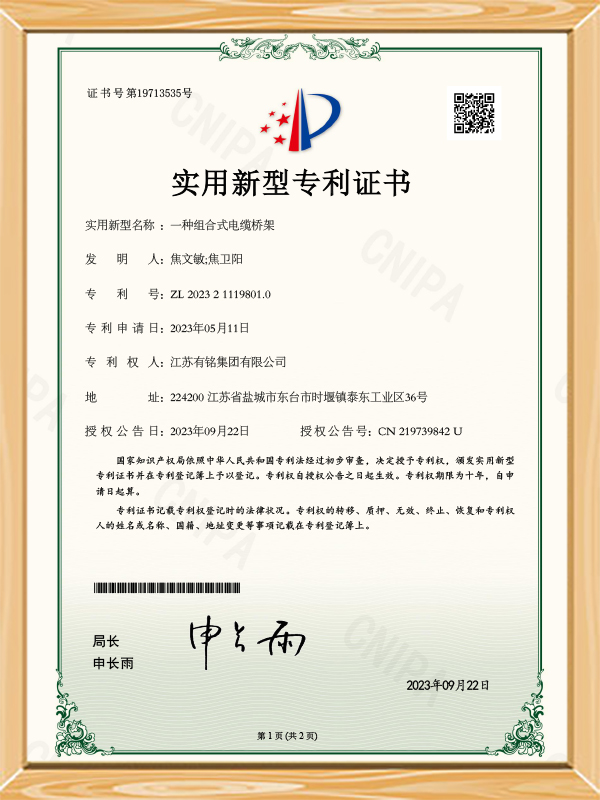

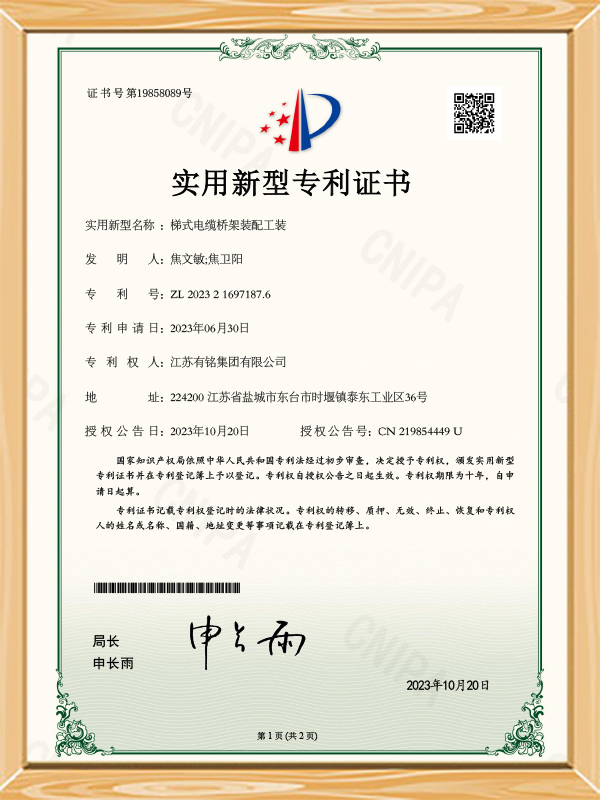

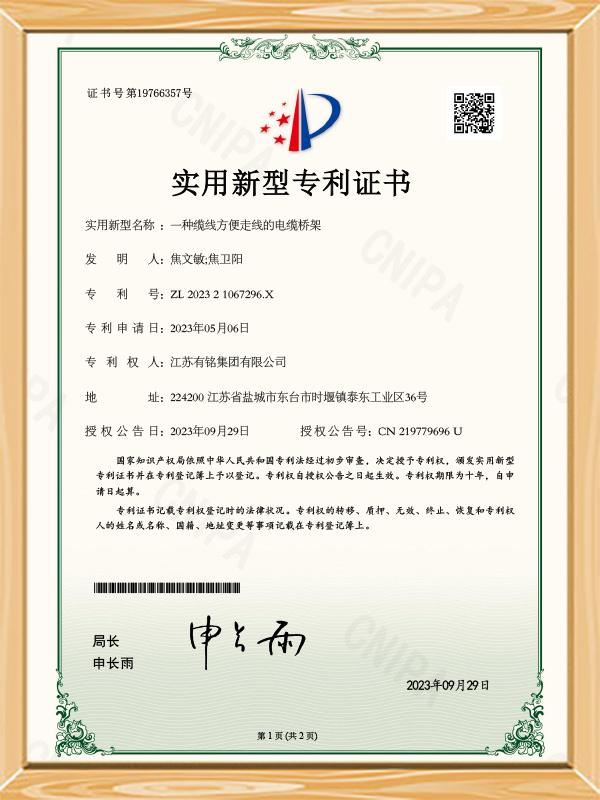

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

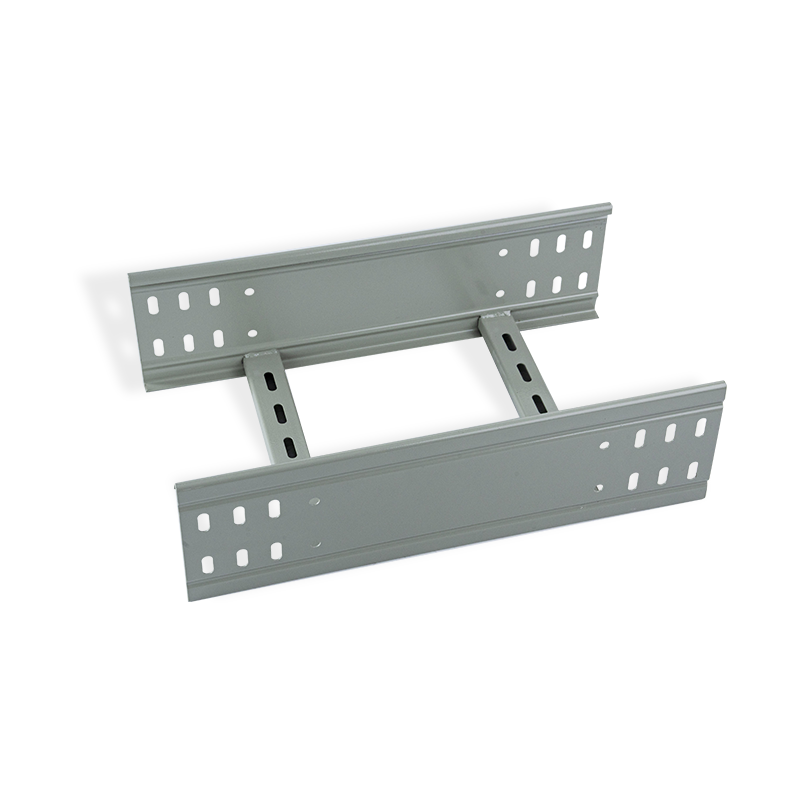

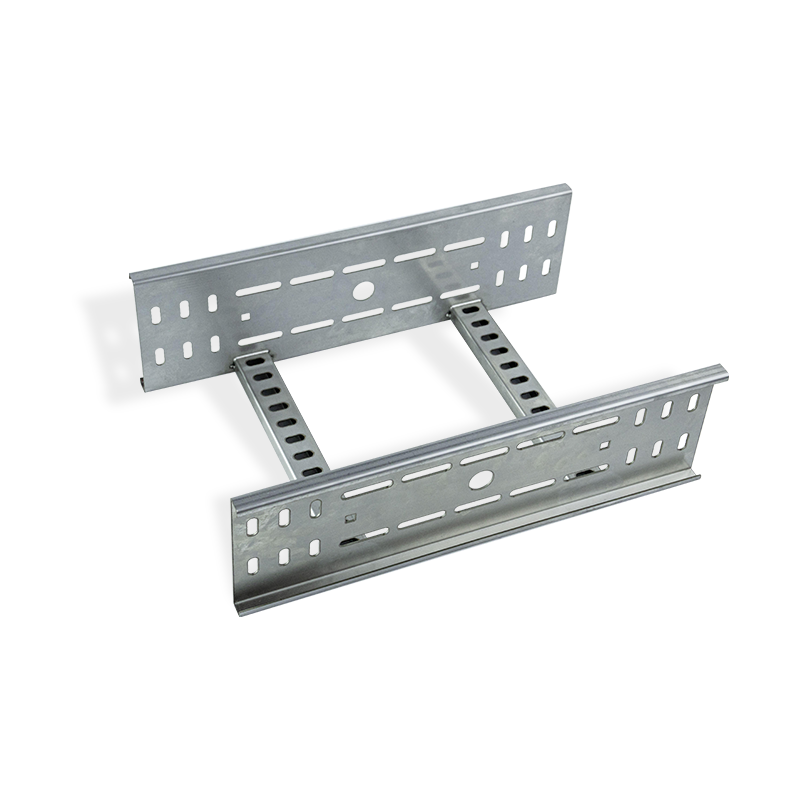

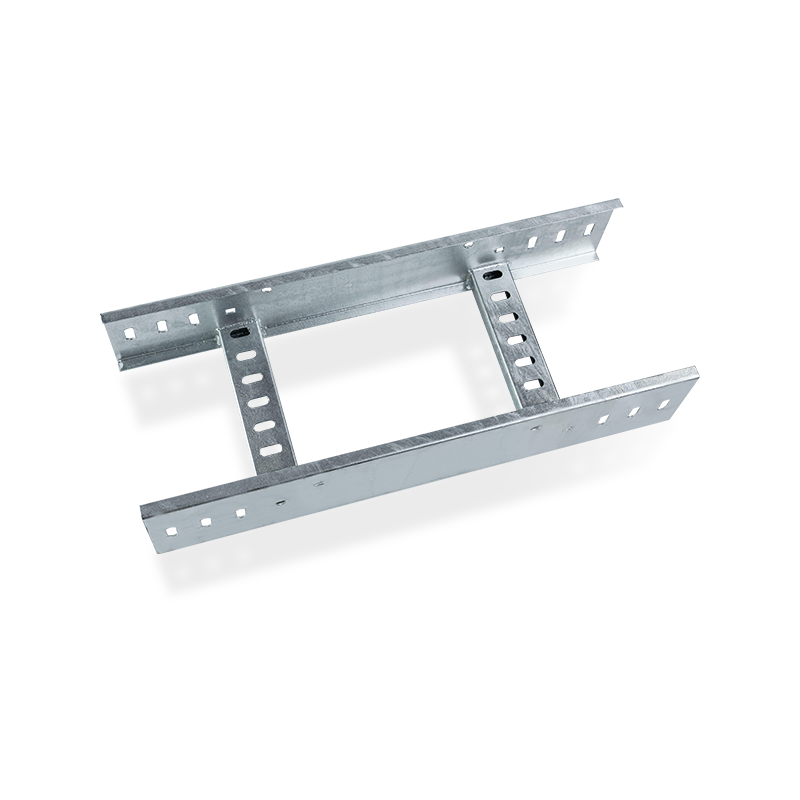

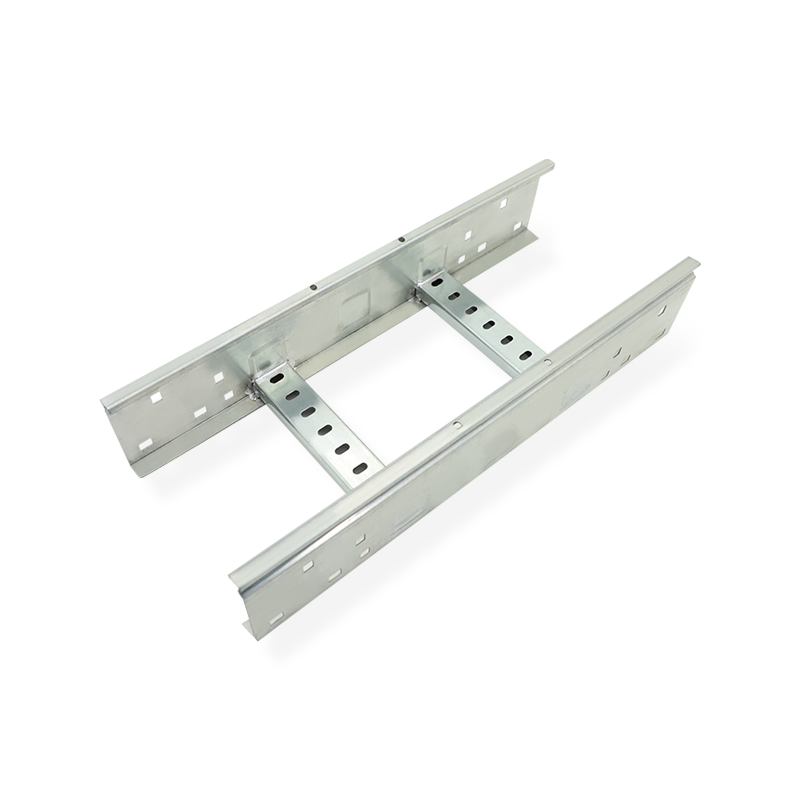

How does the structural design of the lightweight ladder cable tray consider factors such as bearing capacity, heat dissipation performance and cable laying convenience?

Light ladder cable tray plays a key role in the field of power infrastructure, and its structural design needs to comprehensively consider multiple factors such as bearing capacity, heat dissipation performance and cable laying convenience.

Structural design considerations of bearing capacity

Bearing capacity is one of the core elements of the structural design of lightweight ladder cable trays, which is related to the safe and stable operation of the entire cable system. When designing, the frame structure of the bridge is the basis for ensuring the bearing capacity. Usually, high-strength steel is used as the main material, such as the cable tray of Jiangsu Youming Group Co., Ltd., which uses high-quality steel to provide material guarantees for bearing capacity. The crossbeams and longitudinal beams of the bridge form a stable frame, and the reasonable design of the crossbeam spacing is crucial. Generally, the appropriate crossbeam spacing is determined according to the weight and number of cables through precise mechanical calculations. Too small spacing will increase cost and material consumption, and too large spacing will not effectively support the weight of the cable. By optimizing the crossbeam spacing, it is possible to achieve reasonable use of materials while ensuring the bearing capacity.

The side and bottom plates of the bridge also have an important impact on the load-bearing capacity. The thickness of the side and bottom plates needs to be selected according to the load-bearing requirements. Thicker plates can bear greater weight. At the same time, the structural design of the side and bottom plates will adopt reinforcement ribs or folding edges to enhance their rigidity and anti-deformation ability. The reinforcement ribs can disperse the pressure generated by the weight of the cable and prevent the side and bottom plates from bending or sinking under long-term load. This structural design is like the beams and columns in the building, providing solid support for the bridge. In practical applications, strict load testing is the key link to ensure that the load-bearing capacity meets the standards. Before leaving the factory, each cable tray product of Jiangsu Youming Group Co., Ltd. will undergo a comprehensive load test to simulate the load-bearing conditions under different working conditions. Only products that pass the test will be put on the market, thereby ensuring the safety and reliability of users when using it.

Structural design optimization of heat dissipation performance

Good heat dissipation performance is of great significance to the normal operation and service life of the cable. The unique open structure of the lightweight ladder type cable tray is the basis for achieving efficient heat dissipation. Its ladder-like shape allows air to circulate freely around the cable to form natural convection. This open design avoids the accumulation of heat in the cable due to the closed environment, just like creating a well-ventilated space for the cable. There is a large gap between the crosspiece and the side plate of the bridge, which further increases the air circulation area and speeds up the heat dissipation.

In the selection of materials, heat dissipation performance will also be considered. Metal materials have good thermal conductivity and can quickly conduct the heat generated by the cable. At the same time, the surface treatment process of the bridge will also affect the heat dissipation. The galvanizing or powder spraying process adopted by Jiangsu Youming Group Co., Ltd. can not only enhance the corrosion resistance of the bridge, but also improve the heat dissipation effect of the surface to a certain extent. The smooth surface helps the flow of air, reduces air resistance, and promotes heat dissipation. In addition, in some special environments with higher requirements for heat dissipation, the heat dissipation performance can be further improved by adding heat sinks or heat dissipation holes. The heat sink can increase the heat dissipation area and dissipate the heat into the air faster; the heat dissipation hole can accelerate the circulation of air, form a stronger convection, effectively reduce the operating temperature of the cable, and ensure the stable operation of the cable.

The structural design of the convenience of cable laying reflects the convenience of cable laying. The convenience of cable laying directly affects the construction efficiency and cost of the project. The lightweight ladder-type cable tray takes this into full consideration in its structural design. Its modular design is an important factor in improving the convenience of cable laying. The cable tray of Jiangsu Youming Group Co., Ltd. adopts a modular design. The components can be combined together through simple connections. Without complex tools and professional skills, construction workers can quickly complete the installation of the tray. This design greatly shortens the installation time and reduces labor costs, and is especially suitable for fast-paced engineering projects. The open structure of the tray is not only conducive to heat dissipation, but also convenient for cable laying and maintenance. Construction workers can directly place the cable on the crossbar of the tray without tedious operations such as pipe threading, which greatly improves the construction efficiency. When the cable needs to be replaced or repaired, the open structure also makes the operation more convenient, and can quickly locate and deal with the problem. In addition, the design of the corners, branches and other parts of the tray also fully considers the convenience of cable laying. Through reasonable bending radius and connection method, it is ensured that the cable will not be over-stretched or squeezed when turning and branching, and the insulation layer of the cable is protected from damage. At the same time, the design of these parts also facilitates the construction personnel to organize and fix the cables, making the layout of the entire cable system more neat and beautiful, and convenient for later management and maintenance.

The lightweight ladder type cable tray has achieved product performance improvement and functional improvement through comprehensive consideration and optimization of multiple factors such as bearing capacity, heat dissipation performance and cable laying convenience in structural design. Whether in ordinary industrial environments or special places with demanding performance requirements, the light ladder cable tray can meet different usage requirements with its scientific and reasonable structural design, and escort the safe and stable operation of the power system.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt