If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

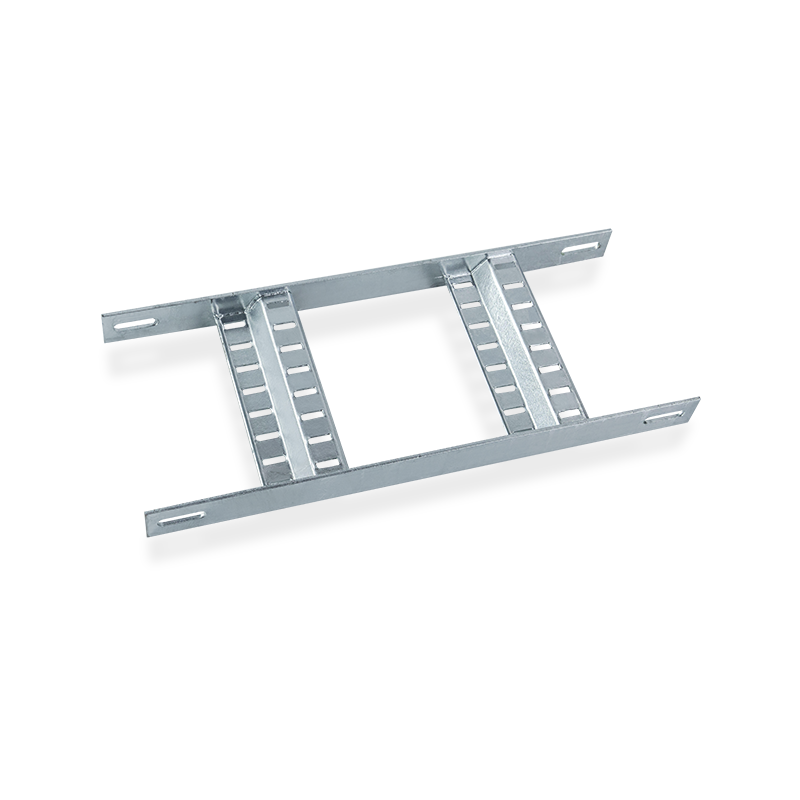

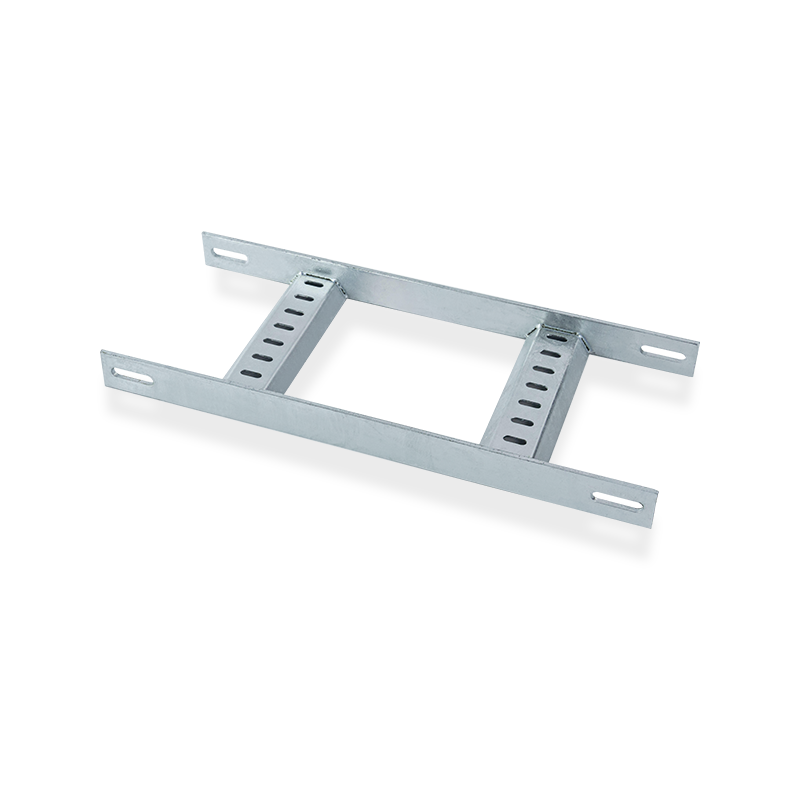

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

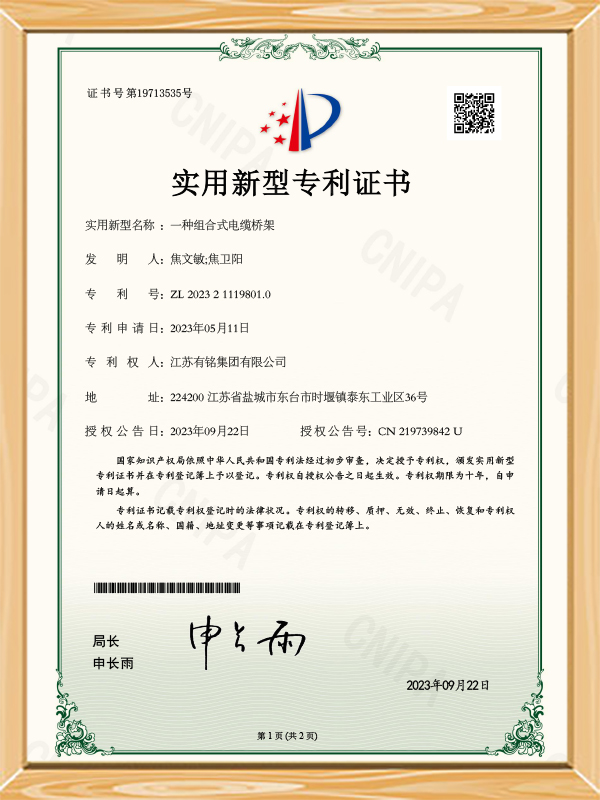

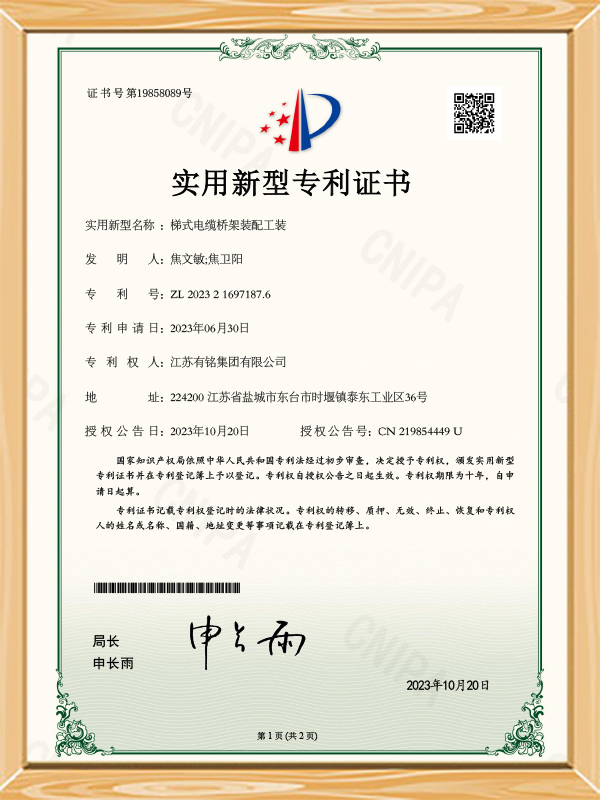

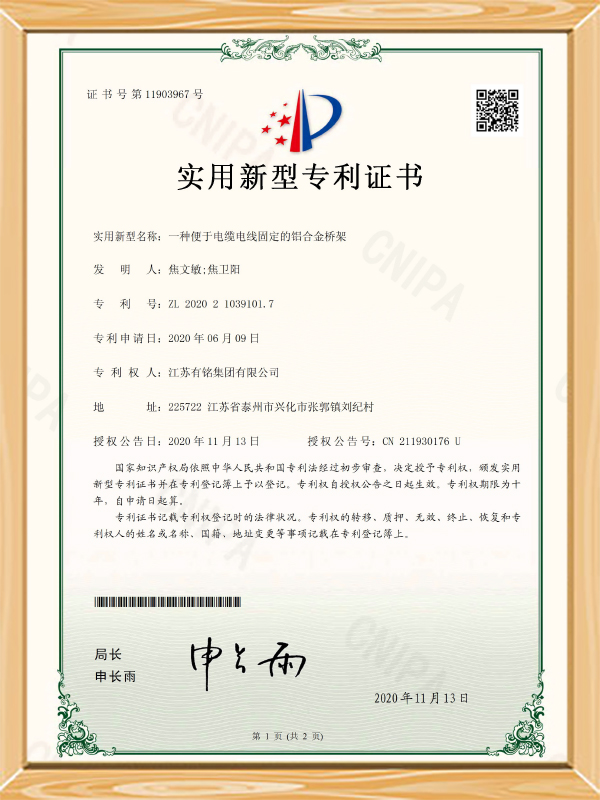

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

How to ensure that the marine/offshore cable ladder tray is firmly and reliably connected to the structure of the ship or offshore platform? What are the considerations for the selection of connection methods and connectors?

Methods to ensure a firm and reliable connection

Accurate design and planning: During the design stage, the layout and connection points of the cable ladder need to be accurately planned according to the structural characteristics of the ship or offshore platform, the cable distribution, and the expected load. For example, it is necessary to consider the swaying and vibration of the ship under different sea conditions and the external forces such as wind, waves, and currents that the offshore platform may face, and reasonably determine the support points and connection methods of the ladder to ensure that it can withstand the stress under various working conditions. When developing new high-strength cable trays, Jiangsu Youming Group Co., Ltd. will fully consider these factors, and optimize the product design to enable it to adapt to the complex environment of different industries, providing a solid foundation for the design of ship/offshore cable ladders.

Strict material selection: The materials used for connection must have high strength and corrosion resistance. The environment in which ships and offshore platforms are located has the characteristics of high salinity and humidity, which can easily lead to metal corrosion. Therefore, materials such as stainless steel and aluminum alloys that are resistant to seawater corrosion should be selected. For example, the products produced by Jiangsu Youming Group Co., Ltd. focus on energy conservation and environmental protection. When selecting materials, they will consider their performance in different environments. For ship/marine engineering cable ladders, they will select high-quality materials suitable for the marine environment to ensure the reliability of the connection from the source.

Standardized installation process: The installation process must be carried out strictly in accordance with the specifications. Ensure that the surface of the connection point is flat and clean, free of impurities such as oil and rust, so as to ensure that the connector and the surface of the structure can fit well. When installing the connector, use precise measuring tools and equipment to ensure that the connection position is accurate and tighten according to the specified torque or tension to avoid loose or tight connection or damage to the structure. The use of fully automatic production lines, including automatic riveting lines, automatic welding lines, etc., these advanced production processes can ensure the accuracy and quality of the product during the production process, provide high-quality marine/offshore cable ladder trays for installation, and also provide guarantees for standardized installation processes.

Regular inspection and maintenance: Regular inspection and maintenance of the connection of the cable ladder is an important measure to ensure its long-term reliable operation. The inspection content includes the tightness of the connectors, whether there are signs of corrosion, whether the ladder structure is deformed, etc. Once a problem is found, it should be repaired or replaced in time. Just like the strict production process control and quality management of the product from raw material procurement to final delivery, the connection of the ship/offshore cable ladder also needs to be tracked and maintained throughout the process to ensure that it is always in good operating condition.

Considerations for connection methods and connector selection

Considerations for connection methods

Welding connection: Welding connection can provide a high-strength connection, so that the cable ladder and the structure of the ship or offshore platform form a whole, with good seismic and fatigue resistance. However, the welding process requires professional technicians and equipment, and it is difficult to disassemble after welding, which is not conducive to later maintenance and modification. In some parts that require high structural integrity and are not easy to perform frequent maintenance, welding connection can be considered. For example, the automatic welding line can ensure the quality and accuracy of welding, and provide technical support for the application of welding connection methods in marine/offshore cable ladder trays.

Bolt connection: Bolt connection has the advantages of easy installation and disassembly, which is convenient for later maintenance and replacement. At the same time, by selecting the appropriate bolt specifications and materials, different connection strength requirements can be met. However, bolt connections need to be careful to prevent loosening, and anti-loosening measures are usually required, such as spring washers, lock nuts, etc. In ships or offshore platforms, bolt connections are a more appropriate choice for some parts that require frequent maintenance or may need to adjust the cable layout.

Riveted connection: Riveted connection can also provide reliable connection strength and has good sealing. Compared with welding, riveting has less thermal impact on the structure and does not change the properties of the material. However, riveting requires special riveting equipment, and it is also not easy to disassemble after riveting. In some areas with high requirements for sealing, such as ship cabins, riveted connections can be considered. Jiangsu Youming Group Co., Ltd. has an automatic riveting line that can complete the riveting process efficiently and accurately, providing quality assurance for the riveting connection of marine/offshore cable ladder trays.

Considerations for the selection of connectors

Strength and load-bearing capacity: The connector must be able to withstand the weight of the cable ladder and the cable, and also consider various external forces that may be generated during the operation of the ship or offshore platform, such as vibration and impact. Therefore, it is necessary to select connectors of appropriate strength grade according to the actual load conditions. For example, for cable ladders on large offshore platforms, since they carry a large number of cables and a large weight, high-strength bolts or rivets are required as connectors.

Corrosion resistance: As mentioned above, the marine environment is corrosive, so the corrosion resistance of connectors is crucial. Corrosion-resistant materials such as stainless steel and aluminum alloy are common choices. In addition, the connectors can also be surface treated, such as galvanizing and nickel plating, to further improve their corrosion resistance. The use of automatic spraying lines ensures the corrosion resistance and consistency of the appearance of the products. Similar processes can also be used for the surface treatment of connectors to extend their service life.

Adaptability: The size, shape and installation method of the connectors must be compatible with the structure of the cable ladder and the ship or offshore platform. For example, the size and spacing of the connection holes of the cable ladder must match the specifications of the bolts or rivets to ensure the tightness and stability of the connection. At the same time, the installation method of the connectors should be convenient for construction operations and can be installed and tightened in the limited space of the ship or offshore platform.

Conductivity and grounding requirements: In ships and marine engineering, cable ladders need to be well grounded to ensure electrical safety. Therefore, connectors should have good conductivity to achieve reliable connection between cable ladders and the grounding system of ships or offshore platforms. When selecting connectors, consider the conductivity of the material and whether it is easy to achieve grounding connection.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt