If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

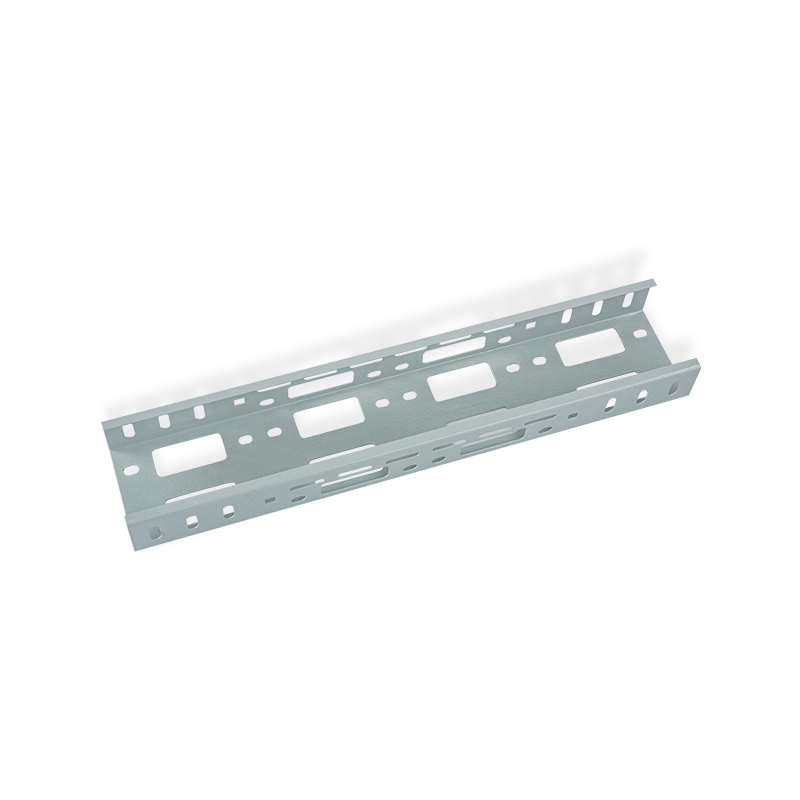

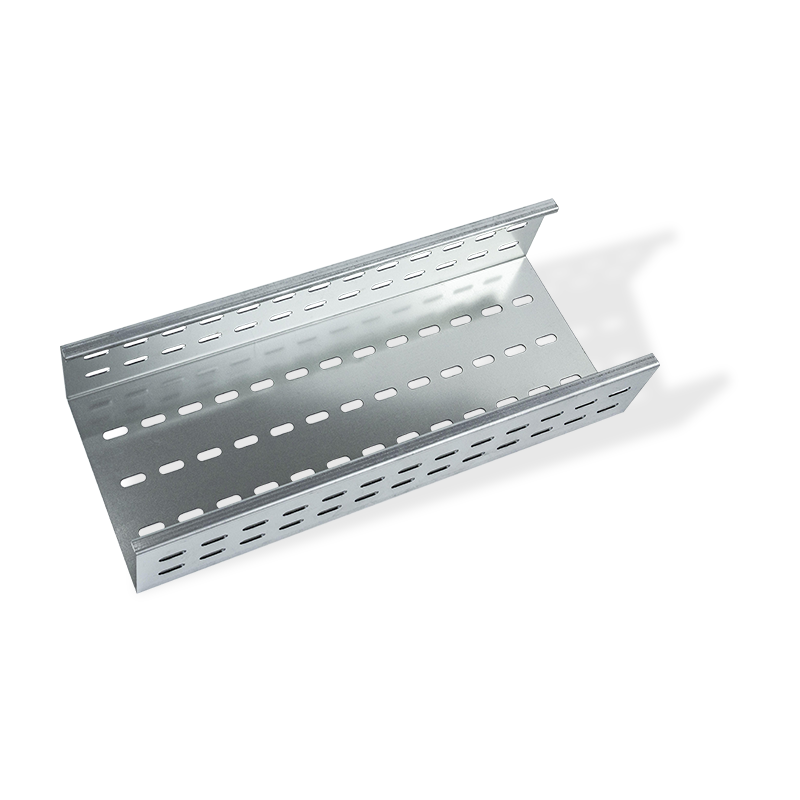

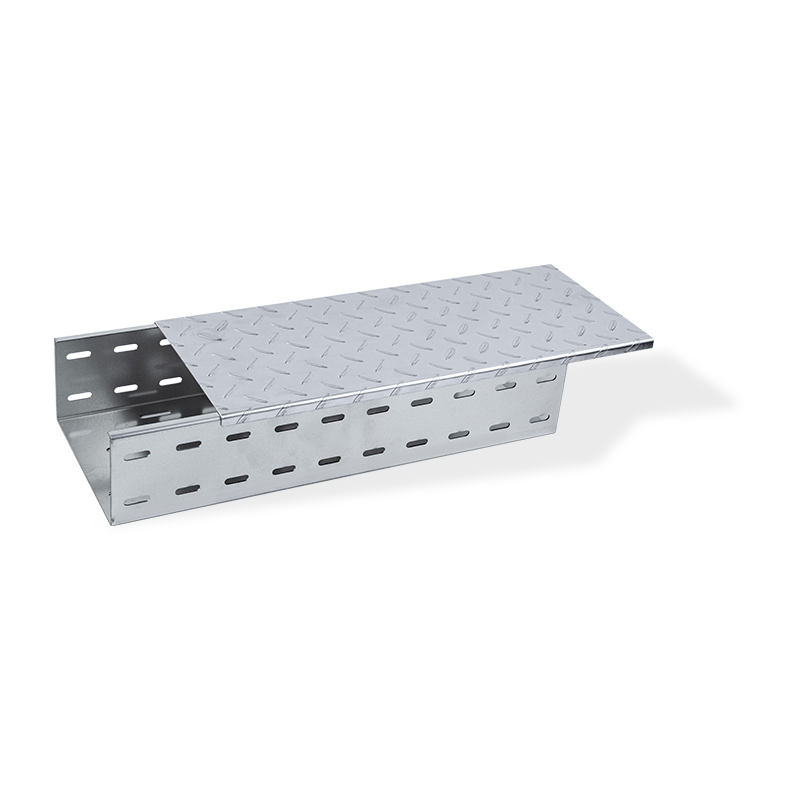

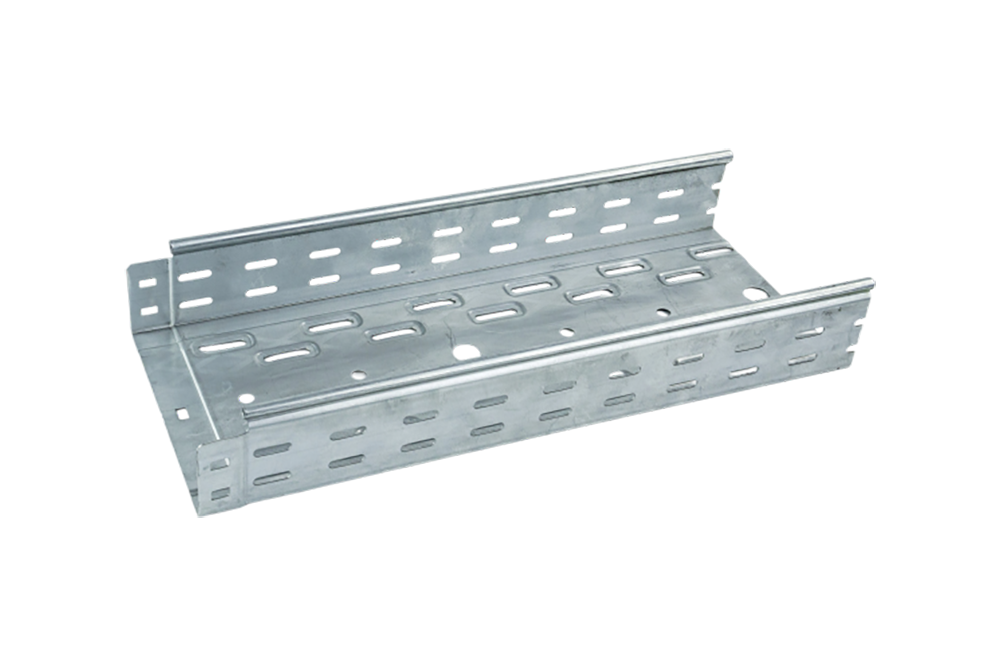

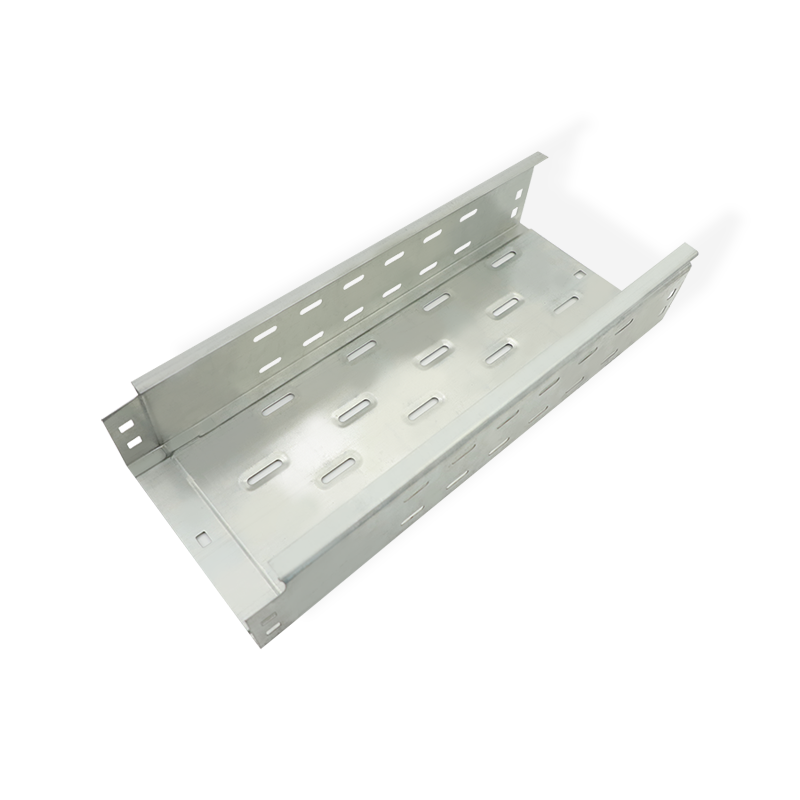

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

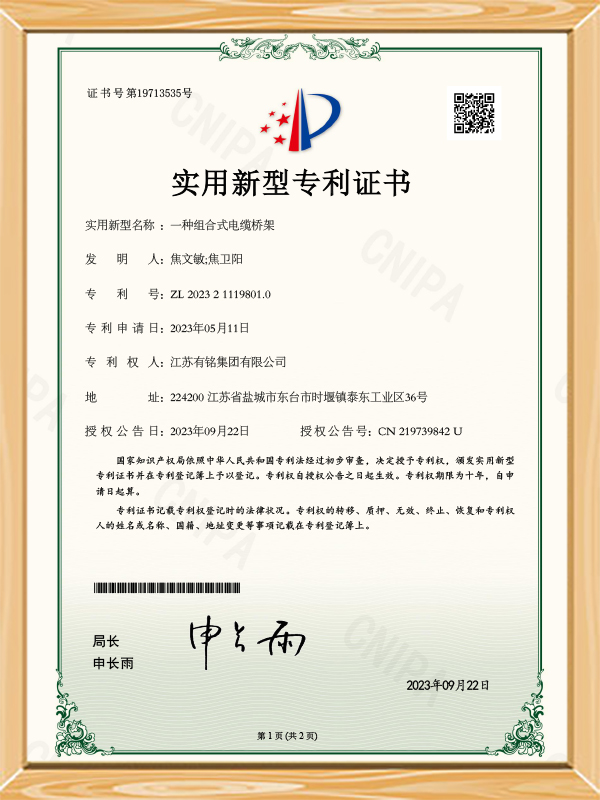

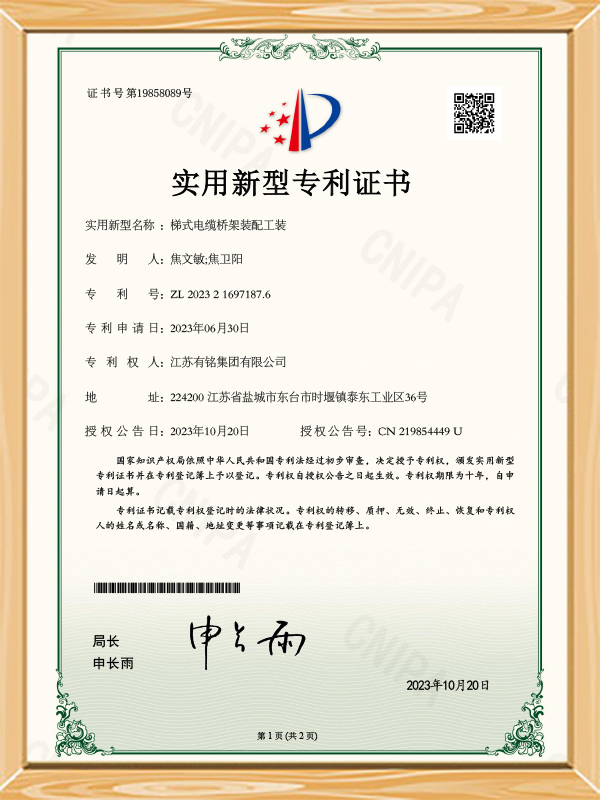

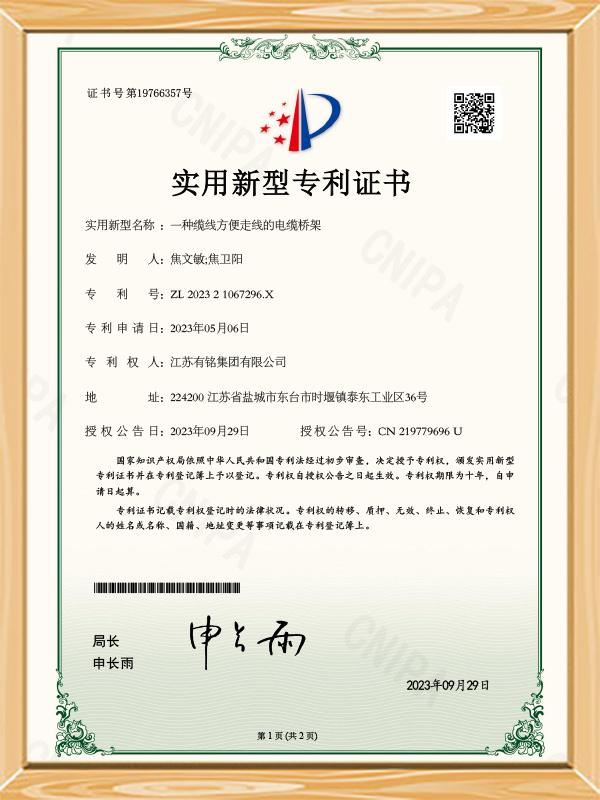

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

How does the punching process ensure the accuracy and uniformity of the hole position when producing the Punched Type Perforated Cable Tray Series?

1. Advanced production equipment lays a solid foundation

The automated production line owned by Jiangsu Youming Group Co., Ltd. is the core element to ensure the accuracy of the punching process. The laser cutting line plays a pivotal role in the punching process. It uses a high-energy laser beam to instantly melt or vaporize metal materials for processing. This non-contact operation mode fundamentally avoids the problem of material deformation caused by pressure in traditional mechanical punching. In actual production, the focusing accuracy of the laser beam can reach the micron level, and it can punch holes with extremely small diameters and smooth edges on millimeter-thick metal sheets, providing strong support for the accuracy of the hole position.

The automatic forming line uses precise mechanical positioning devices and high-precision servo motors to accurately position and pre-process the plates before the bridge plates are formed. When processing large bridge plates, the automatic forming line will first level and calibrate the plates to eliminate the slight deformation of the raw materials during transportation or storage, ensure that the subsequent punching operations are carried out on a stable basis, and further improve the accuracy of the hole position.

The horizontal slitting line and the vertical slitting line are like "cutting masters", which can accurately cut metal coils into plates of appropriate sizes according to production requirements. The size error of these cut plates is extremely small, providing standard and flat raw materials for the subsequent punching process. The automatic riveting line and the automatic welding line are responsible for firmly connecting the various components to ensure that the bridge structure will not be displaced or deformed due to external forces during the punching process. Taking the automatic welding line as an example, the pulse welding technology it uses can automatically adjust the welding parameters according to the thickness and material of the plate, so that the weld is uniform and firm, thereby ensuring the uniformity of the hole position. After the bridge punching is completed, the automatic spraying line will spray a protective coating on its surface to prevent the punched type perforated cable tray series from rusting and corroding during use. The automatic inspection line is like an "electronic eye". It uses high-precision sensors and image recognition technology to monitor the entire production process in real time. Once the production parameters deviate from the standard, an alarm will be immediately issued and adjustments will be made to ensure that every link meets the high standards set by Youming Group.

2. Precision mold design and manufacturing escort

High-precision molds are important tools for achieving precise hole positions and uniform spacing. For the need to punch out regularly arranged porous structures on the bridge, the designers will fully consider factors such as the ductility of the sheet, the stress distribution during punching, and the force conditions of the mold, and optimize the structure and parameters of the mold through multiple simulation analyses. Finite element analysis (FEA) technology is used to predict the deformation of the mold during high-speed stamping, and the mold design is adjusted in advance to ensure that the mold can remain stable in actual production and reduce the risk of hole position deviation caused by mold deformation.

Entering the mold manufacturing link, high-precision processing equipment plays a key role. Using advanced processes such as CNC EDM and slow wire cutting, the dimensional accuracy and surface quality of the mold are strictly controlled. After each set of molds is manufactured,

3. Intelligent production control system checks

The sensors and image recognition technology equipped in Youming Group's production control system are like sensitive "sensory organs" that monitor various parameters in the punching process in real time. During the bridge punching process, the position sensor can accurately detect the position of the punch head to ensure that each punching can accurately fall on the preset hole coordinates; the aperture sensor measures the aperture size in real time through laser scanning, and immediately feeds back to the control system once the aperture deviation is found to exceed the allowable range. Image recognition technology can take photos of the punched holes and compare them with the pre-set hole arrangement model to detect whether the hole spacing is uniform.

Once the data deviates from the preset standard, the system immediately issues an alarm and automatically adjusts the stamping equipment parameters, such as stamping pressure, speed and position, to correct the deviation in time. When the syst

em detects a slight deviation in the hole position in a certain area, it will automatically fine-tune the position of the punch head and appropriately adjust the stamping pressure to ensure that the subsequent holes are restored to the correct position. The system also has powerful data recording and analysis functions, which can deeply mine massive production data. By analyzing the punching data of different batches and different specifications of bridges, it is possible to accurately locate specific conditions that are prone to hole position deviation. Through data analysis, it was found that when producing a certain specification of bridge, when the ambient temperature changes beyond a certain range, the hole position accuracy will be affected. Youming Electric then adjusted the production parameters and process methods in a targeted manner, installed temperature control equipment in the production workshop, maintained a stable ambient temperature, and continuously improved the stability and reliability of the punching process.

Fourth, strict quality control system guarantee

Starting from the inspection of raw materials entering the factory, the quality inspector will strictly test each batch of metal sheets to check whether the material composition, thickness tolerance, surface quality, etc. of the sheet meet the quality standards. The chemical composition of the sheet is detected by a spectrometer to ensure that it has good mechanical properties and corrosion resistance; the thickness of the sheet is measured at multiple points using a thickness gauge to ensure uniform thickness.

During the production process, the quality inspector will regularly conduct detailed inspections and maintenance of the stamping equipment and molds. Before production every day, the hydraulic system and transmission parts of the stamping equipment are checked to ensure stable operation of the equipment; the mold is cleaned and lubricated every week, and the mold surface is checked for wear or cracks, and repaired or replaced in time. Each batch of bridges will be sampled and tested, and the hole position, hole diameter and hole spacing will be accurately measured using professional measuring tools such as vernier calipers and micrometers. During the inspection process, holes in different positions are measured according to strict sampling standards to ensure that the inspection results are representative. Once unqualified products are found, they will be reworked or scrapped immediately to resolutely prevent defective products from flowing into the next process. Organize employees to learn the key points and quality standards of the punching process, conduct practical operation competitions, and reward employees with outstanding performance, providing solid guarantees for the quality of the punching process from the personnel level.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt