If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

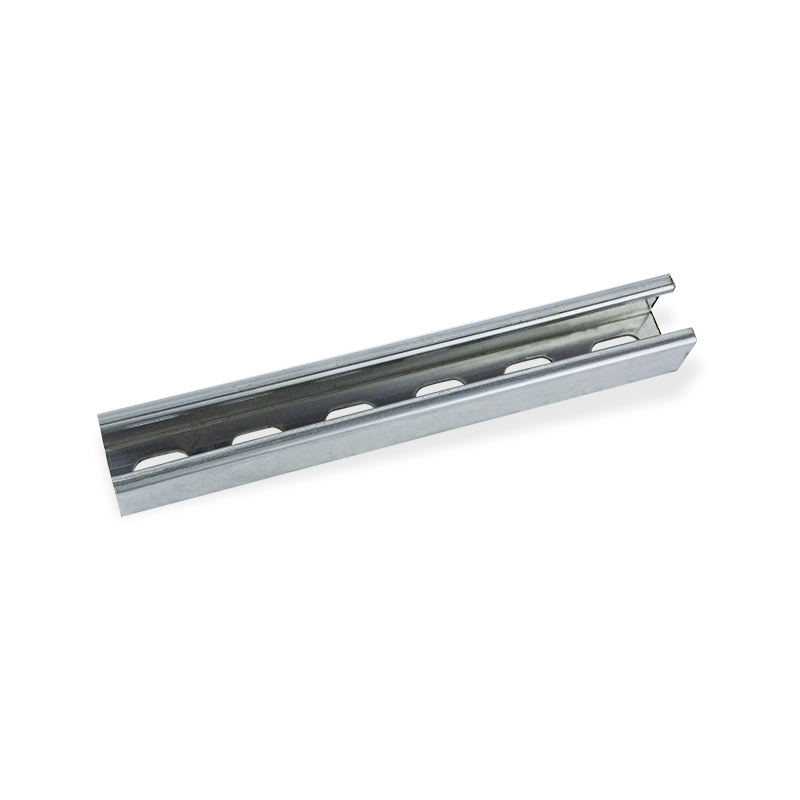

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

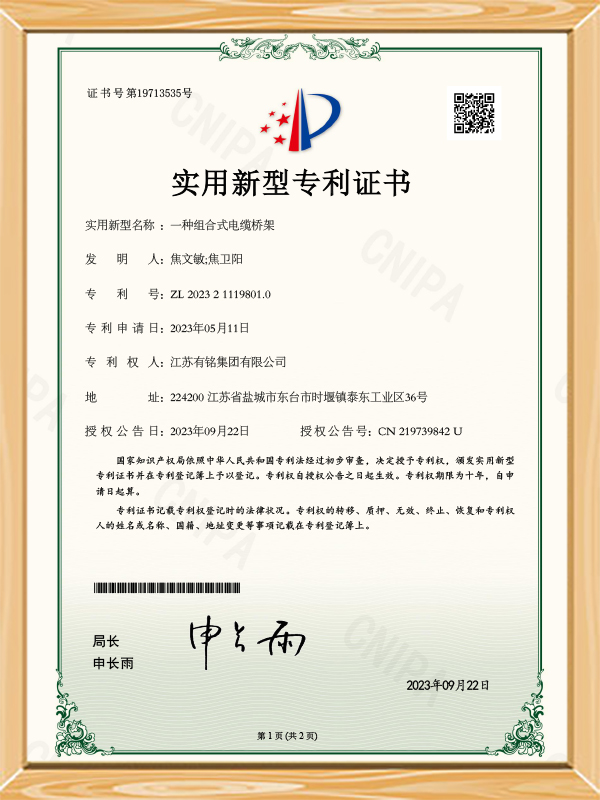

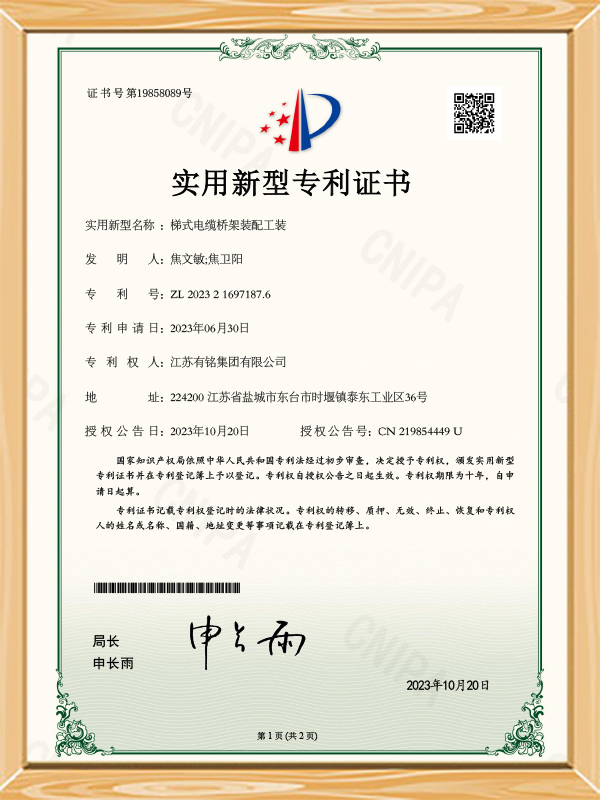

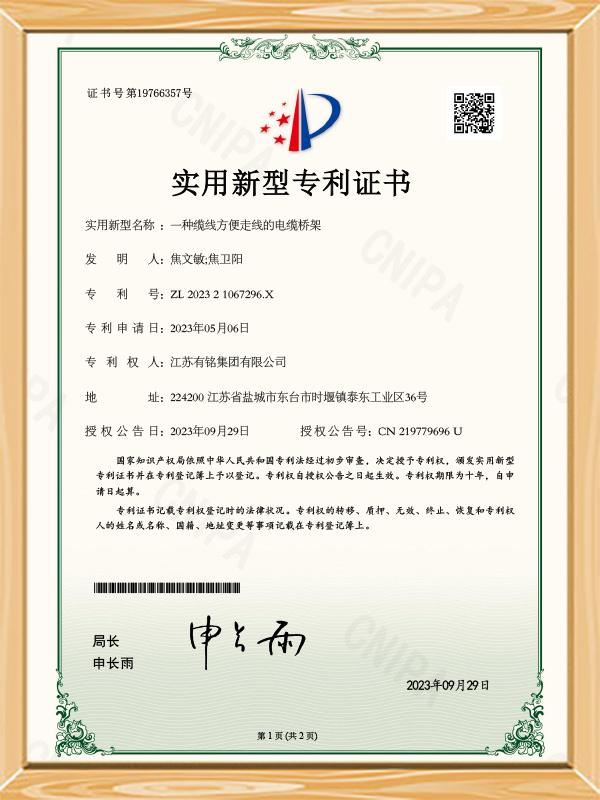

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

How does the structural design of the supporting strut channel cable tray consider the convenience of laying, fixing and maintaining cables? Are there any optimized design measures for cables of different types and specifications?

In terms of the convenience of cable laying, the strut channel cable tray adopts a fully enclosed structural design, which provides great convenience for cable laying. The fully enclosed trough forms a regular channel, just like laying an exclusive "highway" for the cable. Construction workers can place the cables in an orderly manner inside the bridge according to the planned route, without worrying about the cable being entangled or knotted during the laying process, which greatly improves the efficiency of cable laying. The trough cable tray has various length specifications. The bridge produced by Jiangsu Youming Group Co., Ltd. can be customized according to actual engineering needs. Whether it is short-distance local wiring or long-distance large-scale power system laying, it can be flexibly adapted. During on-site installation, its modular design advantages are fully demonstrated, and it can be quickly spliced without complex tools, significantly shortening the time cost of cable laying. For example, in the construction of power systems in some large commercial complexes, the use of trough-type cable trays can complete large-scale cable laying work in a short time and ensure that the project is advanced on time.

For the fixing of cables, the trough-type cable tray has a careful design. A variety of fixing devices are set inside the bridge, such as cable brackets, tie fixing points, etc. The spacing of the cable brackets has been scientifically calculated to ensure the stable support of the cables in the bridge without causing excessive pressure on the cables. Cables of different specifications can reasonably select appropriate bracket spacing according to their weight and diameter to ensure that the cables remain neat and orderly in the bridge. The tie fixing points provide an additional fixing method for the cables. Construction workers can use tie-ties to fix the cables on the bridge to prevent the cables from being displaced due to vibration and other factors during operation. In addition, the convenience of cable fixing was fully considered during the design. The installation and removal of the fixing devices are very convenient, and even if the cables need to be adjusted or replaced in the later stage, they can be easily operated.

In terms of cable maintenance convenience, the strut channel cable tray also performs well. Although it is a fully enclosed structure, the cover design of the bridge is easy to open and close. The trough cable tray cover adopts a special connection method, such as bolt connection or snap connection. The staff can use simple tools to quickly open the cover to inspect, repair or replace the internal cables. Moreover, the fully enclosed structure protects the cables inside the bridge from external dust, debris, etc., reducing the probability of cable failure caused by external environmental factors, thereby reducing the maintenance frequency. At the same time, since the cables inside the bridge are neatly laid and clearly marked, once a failure occurs, the maintenance personnel can quickly locate the problem, greatly improving the maintenance efficiency. In some hospitals, data centers and other places with extremely high requirements for the stability of the power system, the trough cable tray of Jiangsu Youming Group Co., Ltd. ensures the continuous and stable operation of the power system with its good maintenance convenience.

Jiangsu Youming Group Co., Ltd. has also done a lot of work on the optimization design measures for cables of different types and specifications. For small-sized cables, a fine partition structure is designed inside the bridge. These partitions can classify and lay small-sized cables to avoid interference between cables with different functions, and also facilitate the management and maintenance of small-sized cables. For large-sized cables, the load-bearing capacity and internal space of the bridge have been strengthened and expanded. It is made of high-strength steel and has undergone rigorous structural mechanics testing and load testing to ensure that it can reliably support the weight of large-sized cables for a long time. Special designs have also been made at the turning points of the bridge to increase the turning radius, so that large-sized cables can turn smoothly during the laying process and the insulation layer of the cable will not be damaged due to excessive bending. In addition, for some special types of strut channel cable tray, such as fire-resistant cables and shielded cables, trough-type cable bridges also have corresponding adaptation designs. For fire-resistant cables, the bridge uses special flame-retardant materials and manufacturing processes to match the characteristics of fire-resistant cables, and jointly ensure the safe operation of the power system in special circumstances such as fires; for shielded cables, the fully enclosed structure of the bridge can further enhance the shielding effect against electromagnetic interference and ensure the signal transmission quality of the shielded cable.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt