If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

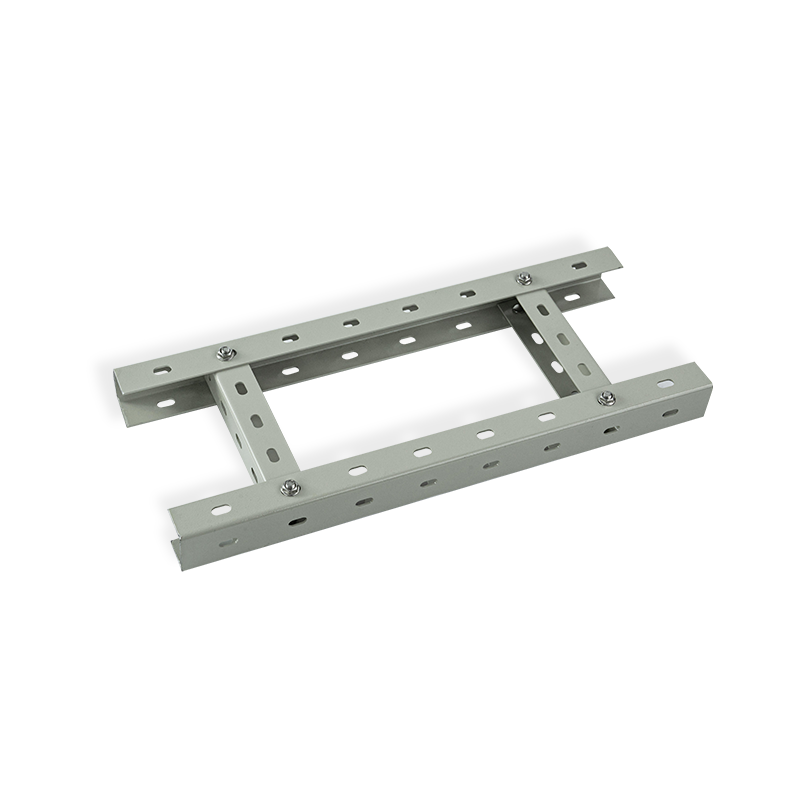

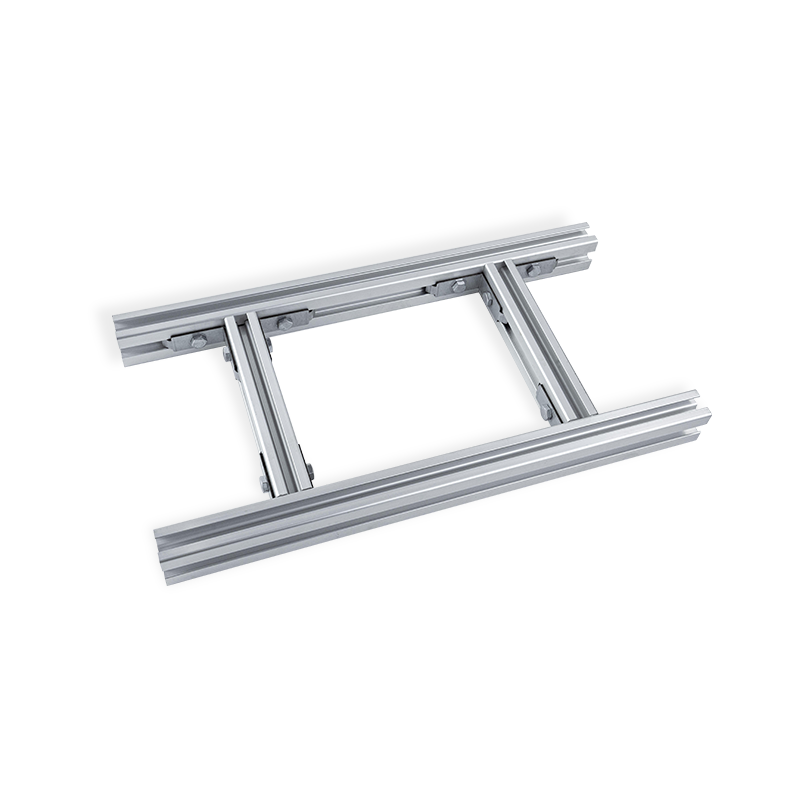

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

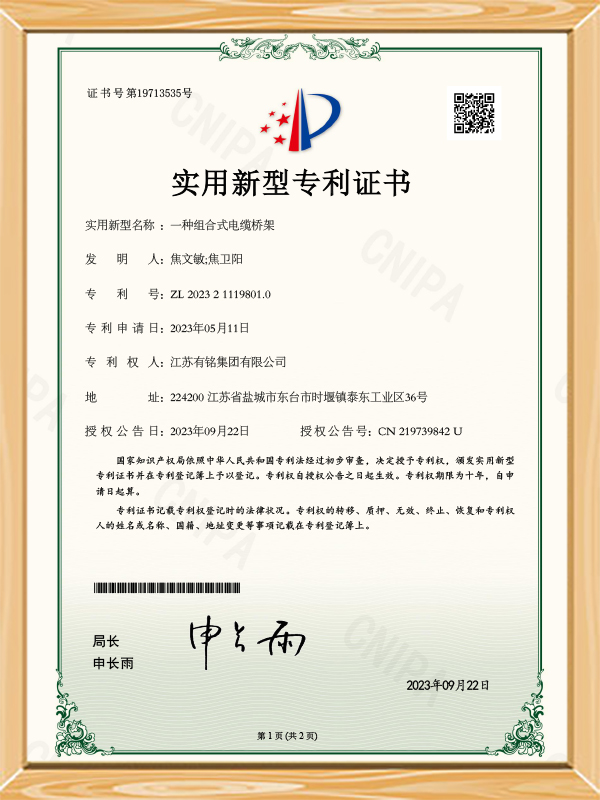

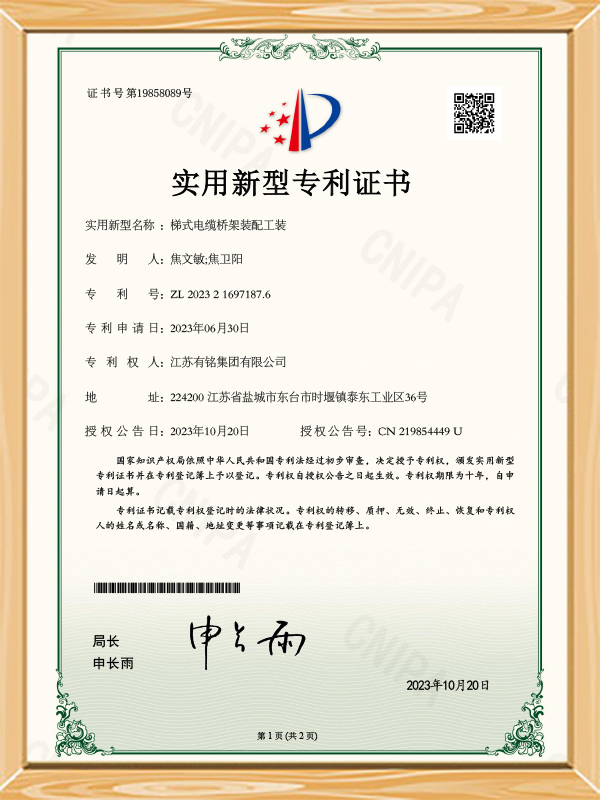

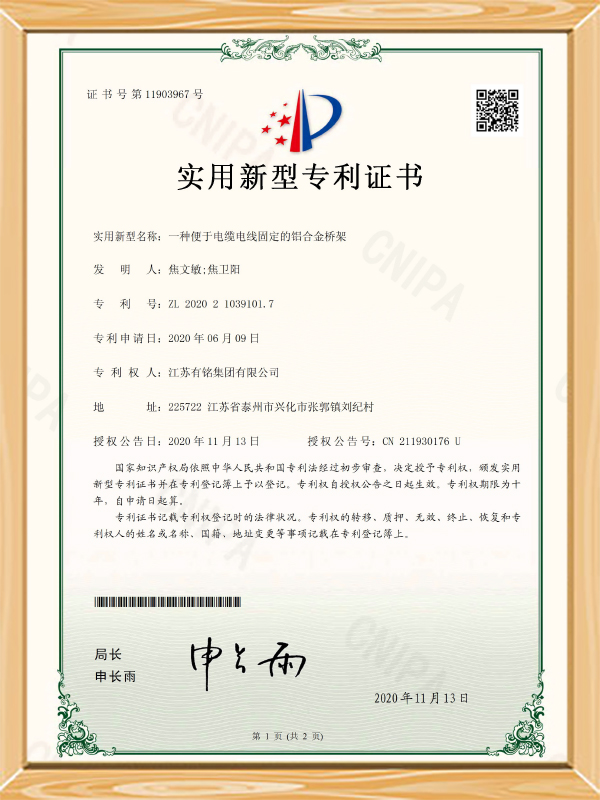

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

How to ensure the dimensional accuracy and stability of the cable ladder, what mold design and processing technology are adopted in the production process of the electrical wiring cable ladder series, and how to calibrate and adjust?

In order to ensure the dimensional accuracy and stability of the cable ladder, mold design, processing technology and calibration adjustment are crucial in the production process of the electrical wiring cable ladder series.

In terms of mold design, accurate three-dimensional modeling must be carried out first. Using advanced computer-aided design (CAD) software, a detailed three-dimensional model is constructed according to the specifications, shape and functional requirements of the electrical wiring cable ladder. This process needs to fully consider the stress conditions and installation environment of the cable ladder in actual use to ensure the rationality of the design. For example, targeted structures are designed for the special needs of different industries such as electricity and transportation for cable ladders. During the design, the structural parameters of the mold are optimized according to the standards and actual application scenarios of different industries to ensure that the produced cable ladder can meet the use requirements of various industries.

The selection of mold materials is also very critical. High-strength and high-wear-resistant mold steels such as Cr12MoV and SKD11 are usually selected. These materials have good hardness and toughness, can maintain the shape and dimensional accuracy of the mold during a long production process, and reduce the wear and deformation of the mold. When purchasing raw materials, strict quality inspection is carried out on the mold steel to ensure that the various performance indicators of the material meet the production requirements and ensure the quality of the mold from the source.

The processing technology of the mold directly affects the dimensional accuracy and stability of the electrical wiring cable ladder. CNC machining is one of the core processes. Through CNC machine tools, high-precision cutting, milling and drilling operations can be performed on the mold. During the processing, advanced processing tools and reasonable cutting parameters such as cutting speed and feed rate are used to improve processing accuracy and surface quality. For example, when processing the key parts of the mold, a smaller cutting depth and feed rate are used to ensure the accuracy of the size. The automatic molding line of Jiangsu Youming Group Co., Ltd. adopts CNC machining technology, which can accurately control the molding process of the mold, so that the dimensional error of each component of the electrical wiring cable ladder is controlled within a very small range.

Electrospark machining is also a commonly used process in mold processing. For some mold parts with complex shapes and high precision requirements, electrospark machining can play a unique advantage. It gradually removes the mold material through the high temperature generated by electric spark discharge, thereby processing the required shape. This processing method can achieve high-precision processing and can meet the complex structural requirements of the cable ladder mold. In the production process, according to the specific situation of the mold, the EDM process is reasonably selected to ensure the accuracy and quality of the mold.

In order to ensure the dimensional accuracy of the mold, precise grinding and polishing are required after the processing is completed. Grinding can eliminate the surface roughness and dimensional errors generated during the processing process, making the mold surface smoother; polishing can further improve the finish of the mold surface, reduce the friction of the product during the molding process, and improve the demolding performance of the product. Jiangsu Youming Group Co., Ltd. has professional grinding and polishing equipment that can perform fine processing on the mold to ensure that the surface quality of the mold meets production requirements.

In terms of mold calibration and adjustment, regular inspection and calibration are essential links. Use high-precision measuring instruments, such as three-coordinate measuring machines, to detect the key dimensions and shapes of the mold. Compare the measurement results with the design drawings. Once the dimensional error is found to exceed the specified range, it needs to be adjusted in time. Adjustment methods include trimming, grinding or replacing worn parts of the mold. Jiangsu Youming Group Co., Ltd.'s automatic inspection line is equipped with advanced measuring equipment, which can monitor the mold in real time, find problems in time and make adjustments to ensure that the accuracy of the mold is always in good condition.

In addition, the mold will be subjected to various forces during use, causing deformation and wear of the mold. In order to extend the service life of the mold, the mold needs to be maintained and serviced regularly. Lubricate the moving parts of the mold, check whether the fastening parts of the mold are loose, and replace the parts with severe wear in time. Formulate a strict mold maintenance system to ensure that the mold always maintains good performance during use, thereby ensuring the dimensional accuracy and stability of the cable ladder.

In the production process of the electrical wiring cable ladder series, through reasonable mold design, advanced processing technology and strict calibration and adjustment measures, the dimensional accuracy and stability of the cable ladder can be effectively guaranteed. Whether it is the refinement of mold design, the precision of processing technology, or the strictness of calibration and adjustment, it reflects the company's high attention to product quality.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt