If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

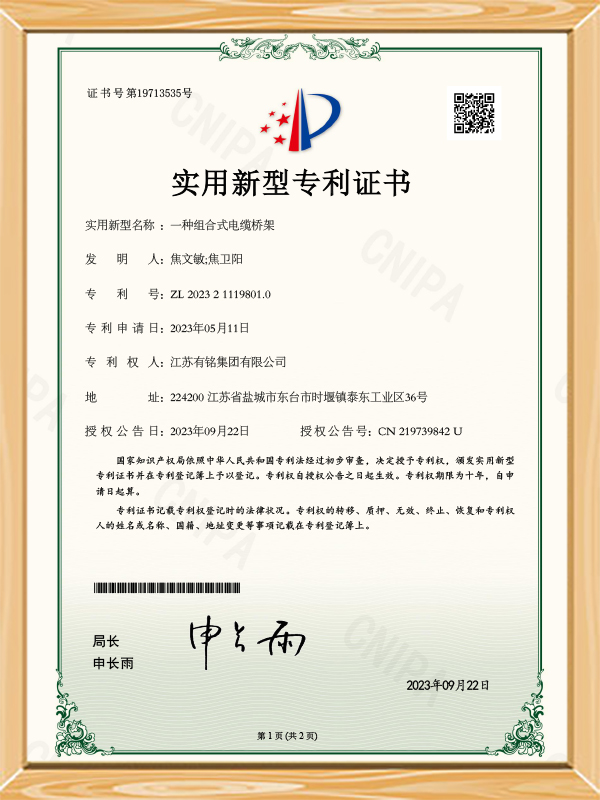

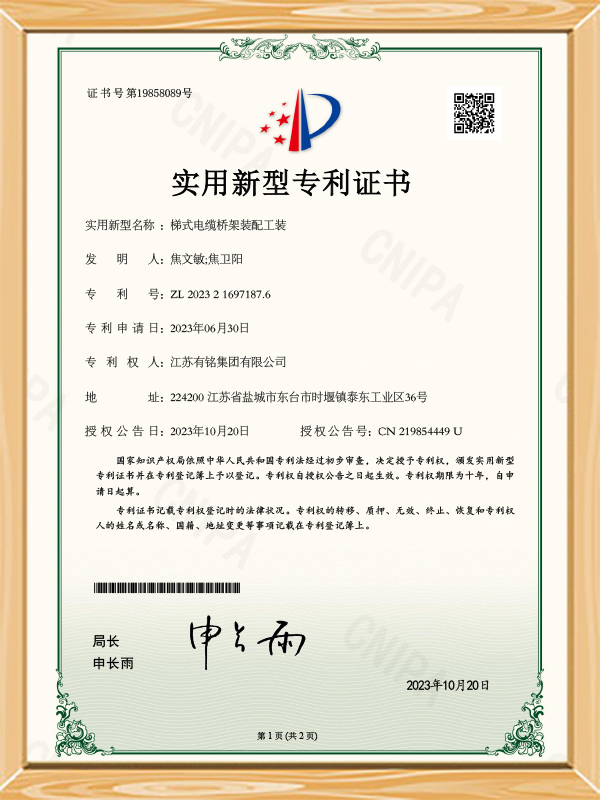

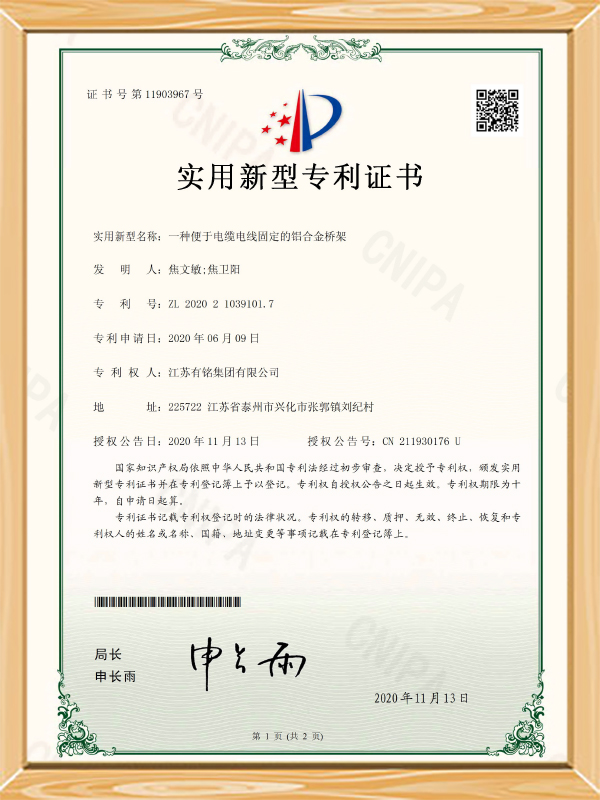

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

What Makes Ground Systems Steel Mounting Structures Essential for Solar Energy Success?

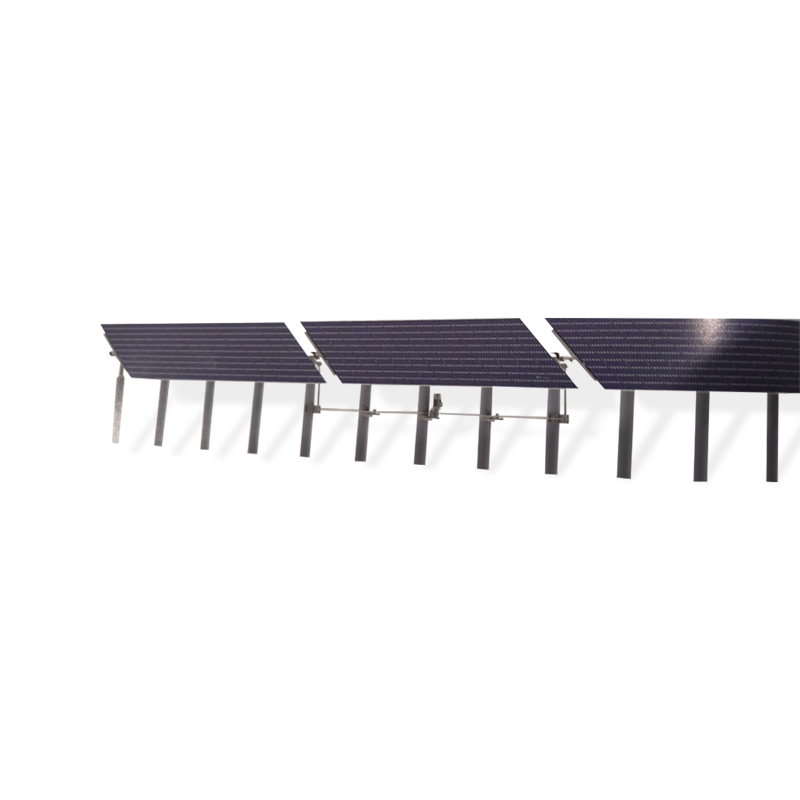

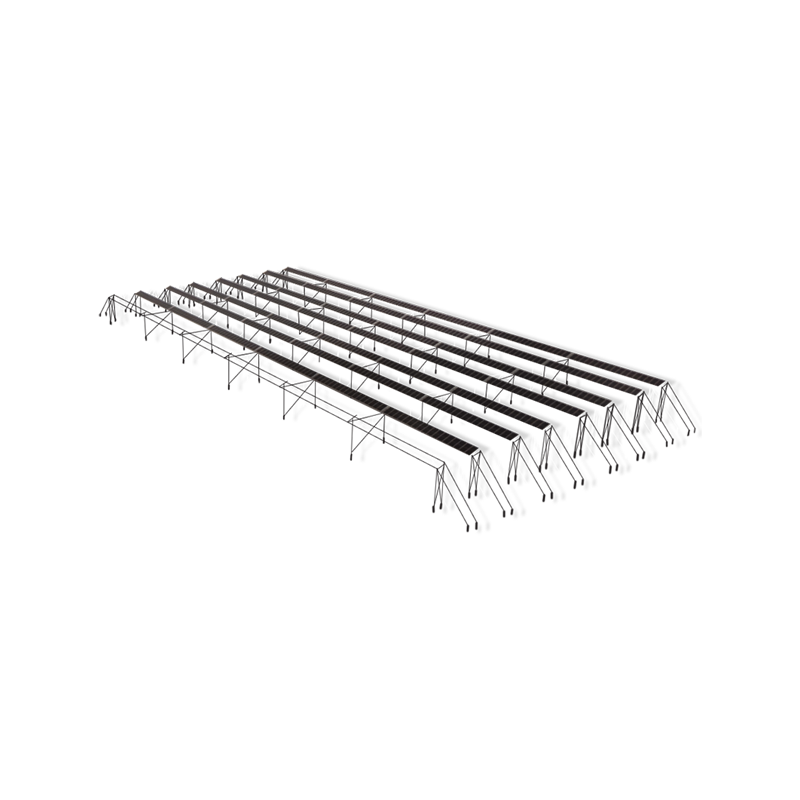

Against the backdrop of the rapid transformation of the global energy structure, solar energy, as a sustainable and clean form of energy, is gradually becoming the leading energy source in countries around the world. With the vigorous development of the photovoltaic industry, the technology and quality of photovoltaic support systems are increasingly becoming key factors in ensuring the efficiency and stability of solar power generation. Among the many support systems, Ground Systems Steel Mounting Structure is widely favored for its strong structural stability, wide adaptability and convenient installation.

The basic function of the ground mounting system is to provide firm and lasting support for photovoltaic modules. In a changing outdoor environment, steel structure supports must withstand long-term erosion from natural factors such as wind, snow, earthquakes, and corrosion. Therefore, the selection of materials and the design of the structure must meet extremely high standards. Compared with aluminum alloy supports, steel structures have higher strength and bearing capacity, especially in large photovoltaic power stations and complex terrain conditions, and can better demonstrate their dual advantages of stability and economy.

As China's leading supplier and OEM/ODM manufacturer of ground system steel structure supports, Jiangsu Youming Group Co., Ltd. has always been at the forefront of the industry. With its mature technology accumulation, advanced manufacturing equipment and strict quality control system, Youming Group not only provides high-performance bracket systems for domestic and foreign markets, but also has strong R&D capabilities in project customization. Its products are widely used in solar power stations of various sizes, from deserts to plateaus, from the seaside to inland areas, and can maintain excellent stability and durability.

In terms of manufacturing technology, Youming Group uses high-strength materials such as hot-dip galvanized steel and carbon steel, and cooperates with precision stamping, welding, heat treatment and other processes to effectively extend product life and reduce later maintenance costs. Its modular design concept also makes the installation process more efficient and fast, greatly shortening the project construction cycle. This not only helps to improve the project return rate, but also conforms to the current trend of rapid deployment of global energy projects.

From an environmental perspective, steel structure brackets also have advantages in life cycle management. Its material recovery rate is high, which is in line with the concept of green manufacturing. At the same time, it can be combined with environmental protection and anti-corrosion processes to reduce the impact on soil and groundwater. Driven by the goals of "carbon neutrality" and "green energy", such sustainable structural solutions are particularly important.

As the photovoltaic market matures, users' requirements for products are no longer limited to "easy to use". Safety, economy, aesthetics, flexibility and other comprehensive performances are becoming the standard for judging the value of a photovoltaic bracket system. And Youming Group has continued to make efforts in these aspects and continuously launched innovative solutions that meet different application scenarios. For example, its product performance has won high recognition in the market in terms of windproof design in high wind pressure areas, corrosion resistance in saline-alkali areas, and flexible layout capabilities in irregular terrain.

As an "invisible but indispensable" part of the solar energy system, the quality and design of the ground steel structure bracket are directly related to the safety and power generation efficiency of the entire power generation system. An excellent bracket system can not only stabilize the components and extend the service life, but also improve the absorption efficiency of solar energy and maximize energy utilization through reasonable inclination design and layout optimization.

So, back to the original question: What Makes Ground Systems Steel Mounting Structures Essential for Solar Energy Success? The answer is not only the solidity of the material and the rationality of the structure, but also the indispensable technical support and value core in the entire solar energy ecosystem. It is not only the "foundation" of the components, but also the "pillar" of the green future.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt