If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

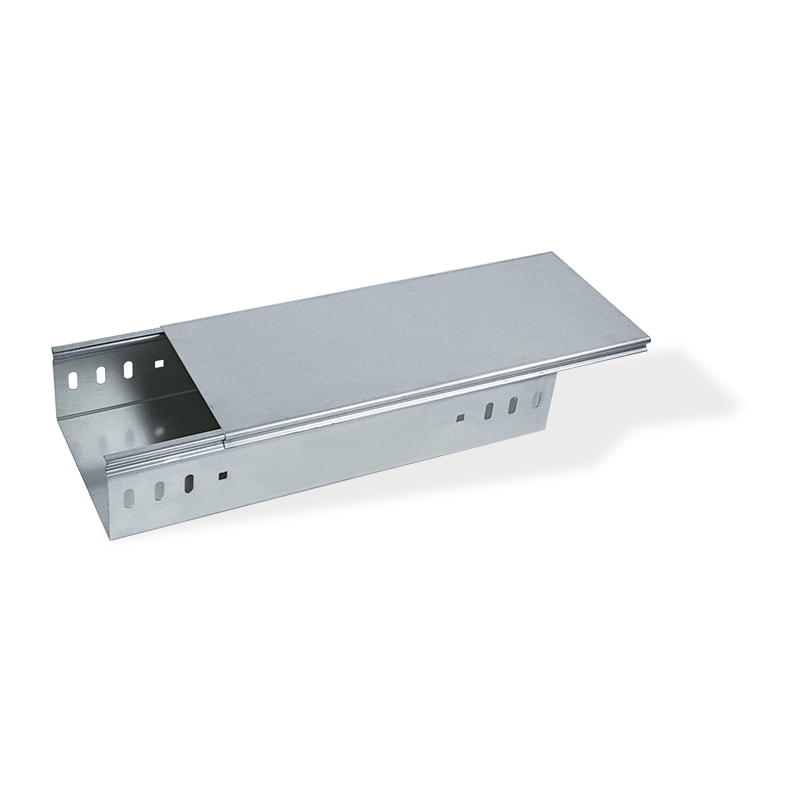

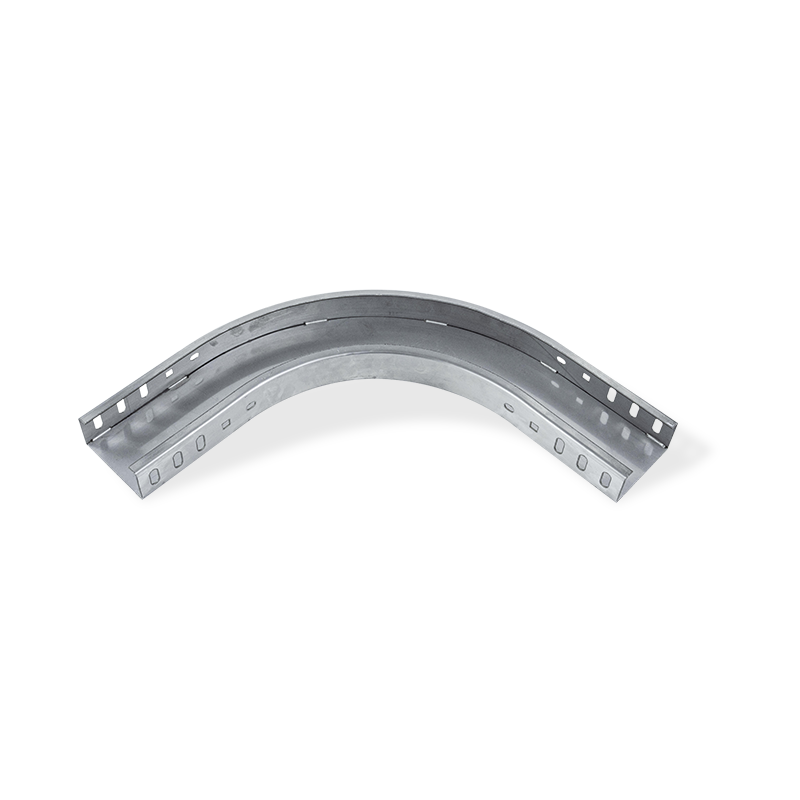

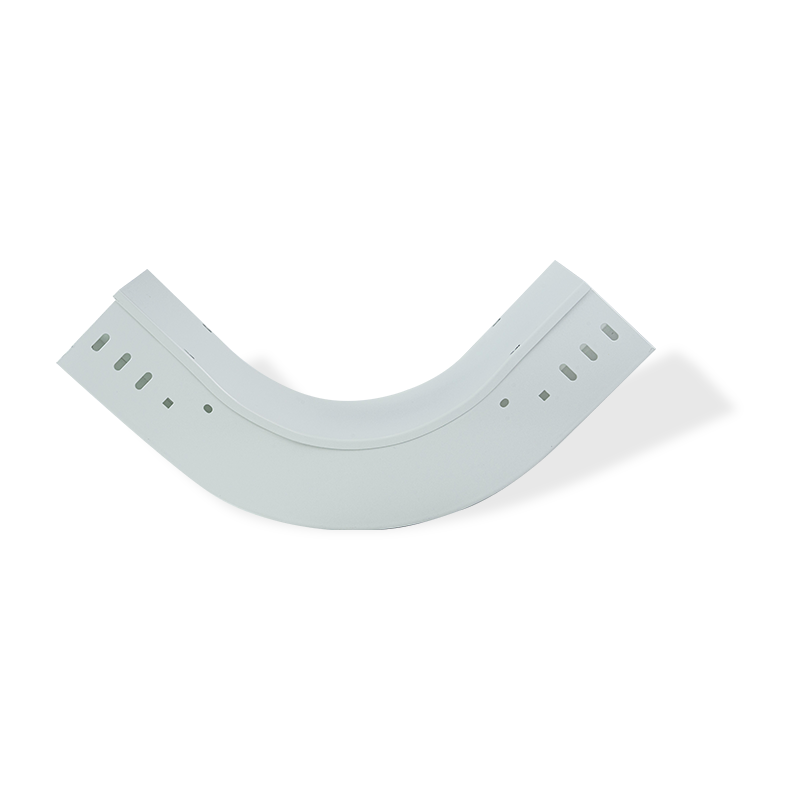

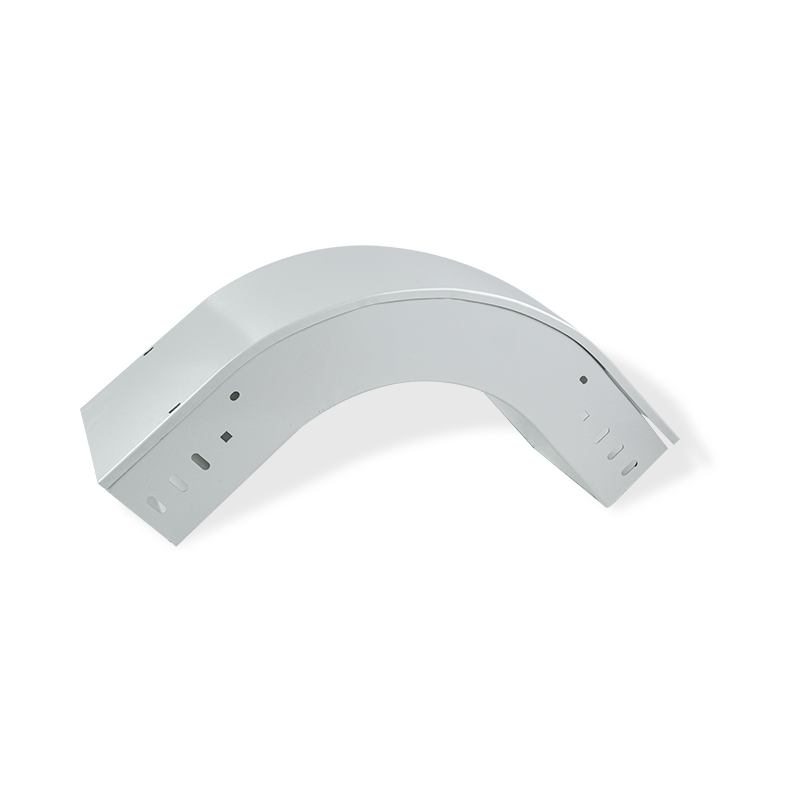

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

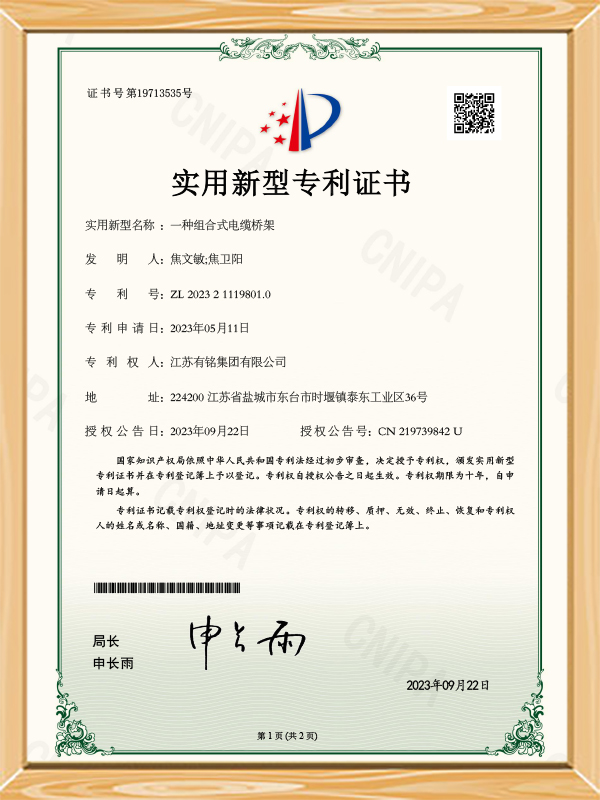

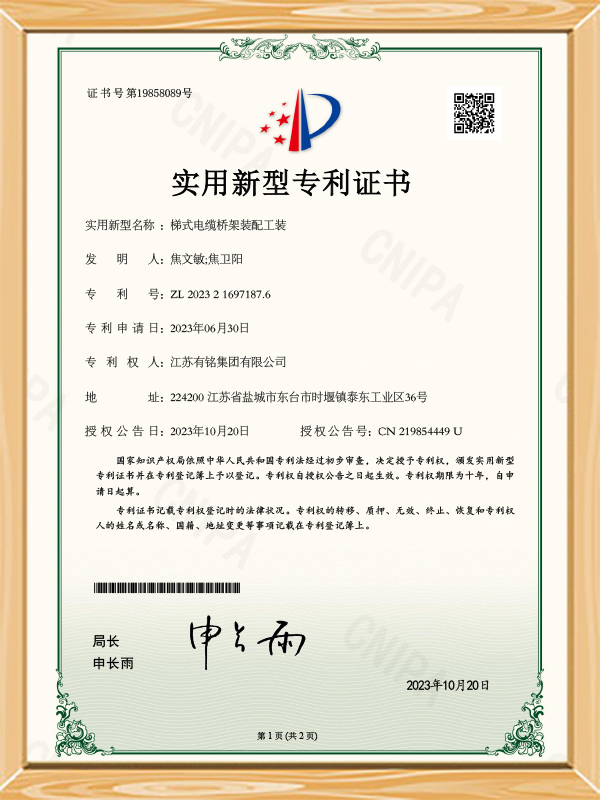

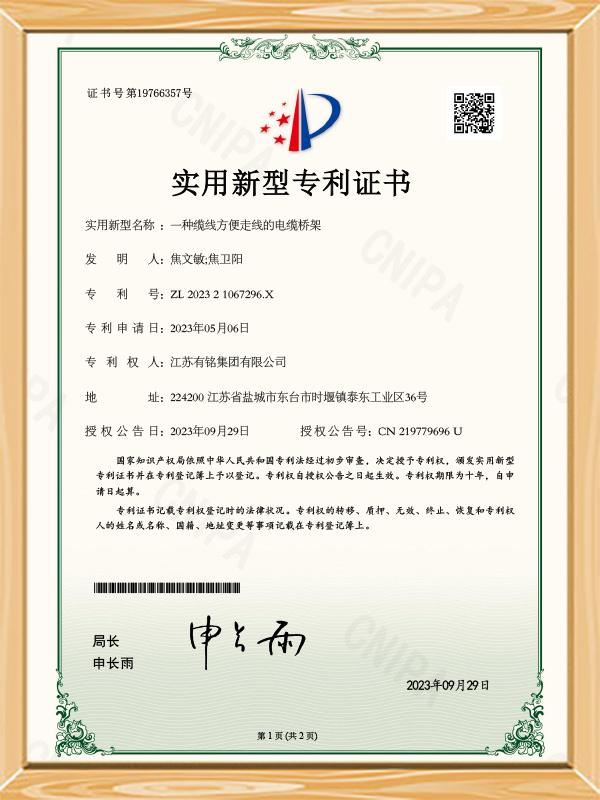

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

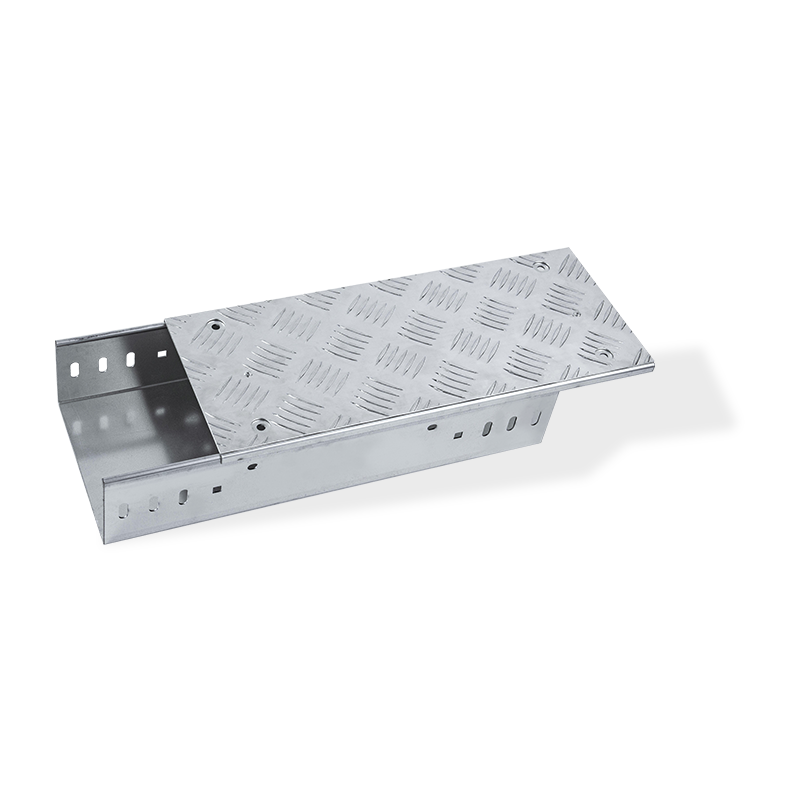

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

How to ensure the precise forming and firmness of the anti-slip structure of Through Type Anti Slip Cable Tray Series during the production process?

The first step of production is the processing of raw materials, and the horizontal slitting line and the vertical slitting line play an important role. The high-quality metal sheets selected by Youming Group must undergo a strict quality inspection process before entering the production line to ensure that their physical properties and chemical composition meet the standards. The two slitting lines are equipped with high-precision servo motors and advanced CNC systems, which can cut metal sheets to precise sizes according to preset parameters. During the cutting process, the system will monitor the flatness and thickness of the sheet in real time, and adjust it in time through the automatic deviation correction device to avoid subsequent problems caused by sheet errors. Accurate cutting not only ensures the rational use of materials and reduces waste, but also provides the prerequisite for the precise production of subsequent anti-slip structures, so that each sheet used for forming can become the basis of high-quality anti-slip structures.

Next, the automatic forming line is the core link to achieve the precise forming of the anti-slip structure. When designing the through type anti slip cable tray series, engineers adopted a unique anti-slip pattern and raised structure design after a large number of experiments and data simulations. This design can not only effectively increase the friction between the cable and the bridge surface, but also fully consider the convenience of cable laying and maintenance. The automatic forming line is equipped with multiple sets of precision molds. These molds are made of high-strength alloy steel. After fine grinding and polishing, the surface finish is extremely high, which can ensure the smooth edge of the anti-slip structure after forming and avoid scratching the cable sheath. According to the design model, the CNC system controls the mold to bend and extrude with micron-level precision, and gradually shapes the metal sheet into the required anti-slip structure shape. During the forming process, the system will monitor the pressure, temperature and other parameters of the mold in real time. Once there is a deviation, it will be automatically adjusted through the hydraulic adjustment device and temperature control system. For example, when the mold temperature is too high and may affect the quality of the sheet forming, the system will start the cooling device to control the temperature within an appropriate range to ensure that each anti-slip structure can meet the design standards. For key dimensions such as the height and spacing of the anti-slip protrusions, the automatic forming line can control the error within a very small range, ensuring the consistency and stability of the product, so that the anti-slip performance of each bridge is maintained at a high standard level.

The firmness of the anti-slip structure is also crucial in the production process. Automatic riveting lines and automatic welding lines play a key role here. The automatic riveting line adopts high-speed precision riveting technology. For some parts that need to enhance the connection strength, special rivets are used to tightly connect the anti-slip parts with the bridge body. These rivets have been specially treated to have high strength and corrosion resistance, and can adapt to different use environments. During the riveting process, the riveting equipment will accurately control the depth and force of the rivets according to the preset pressure and stroke parameters to ensure that the connection is firm and will not cause damage to the bridge body. This connection method is not only firm and reliable, but also can ensure that it will not loosen during long-term use even if it is subjected to vibration, external force, etc.

The automatic welding line uses advanced argon arc welding technology to seamlessly weld the anti-slip structure with the bridge body. The welding robot is equipped with a high-precision visual recognition system that can accurately identify the welding position and accurately control parameters such as welding speed and welding current according to the preset program. During the welding process, in order to ensure the stability of welding quality, the system will monitor the temperature and molten pool state of the welding area in real time, and automatically adjust the welding parameters to ensure that the weld is uniform and full, without defects such as pores and slag inclusions. At the same time, in order to further improve the firmness, after the welding is completed, the welding parts will be ground and polished to eliminate welding stress and enhance the strength of the connection parts. In addition, for some special parts, reinforcement welding technology will be used, such as increasing the size of the weld leg and performing multi-layer welding, to ensure that the anti-slip structure and the main body of the bridge form a solid whole that can withstand the weight of the cable and various external forces.

In addition to the forming and connection process, surface treatment also has an important influence on the performance of the anti-slip structure. The automatic spraying line uses environmentally friendly anti-corrosion paint to spray the surface of the cable bridge. This paint not only has excellent anti-corrosion properties, can effectively resist the erosion of the bridge by harsh environments such as moisture, acid and alkali, and extend the service life, but also can enhance the wear resistance of the anti-slip surface to ensure that the anti-slip effect is not reduced during long-term use. The automatic spraying line is equipped with an intelligent spraying robot, which uses electrostatic spraying technology. It can automatically adjust the angle of the spray gun, spraying distance and paint flow according to the shape and size of the bridge to ensure the thickness and uniformity of the paint spraying. During the spraying process, the system will detect the coating thickness in real time. Once it is found that it does not meet the standard, it will immediately spray again to ensure that every anti-slip structure can be well protected. At the same time, in order to better combine the coating with the bridge surface, the bridge will be pre-treated before spraying, such as sandblasting, chemical cleaning, etc., to remove impurities such as oil and rust on the surface and improve the adhesion of the coating.

Quality inspection is an indispensable part of the production process. Youming Group's automatic inspection line is equipped with a variety of advanced inspection equipment, such as high-precision 3D scanners, strength testers, etc. The 3D scanner can perform a full-scale scan of the size and shape of the anti-slip structure, compare it with the design model, and promptly discover problems such as dimensional deviation. For small dimensional errors, the system will automatically analyze the cause and feedback to the production link for adjustment. The strength tester is used to detect the connection strength between the anti-skid structure and the main body of the bridge. By simulating the stress conditions in actual use, the product is tested for stretching, bending and other tests to ensure that it can withstand the weight of the cable and external forces in actual use. In addition, there are salt spray test chambers, aging test chambers and other equipment to detect the corrosion resistance and aging resistance of the product. Through strict quality inspection, unqualified products are screened out in time. Each through-type anti-skid cable tray series product shipped from the factory must go through multiple inspection processes. Only products that fully meet the quality standards can flow to the market, ensuring the reliability and stability of the product and providing users with trustworthy high-quality products.

Jiangsu Youming Group Co., Ltd. relies on the advantages of fully automated production lines. From raw material processing to molding, connection, surface treatment and quality inspection, every link is strictly controlled to ensure the precise molding and firmness of the anti-skid structure of the through-type anti-skid cable tray series. This not only reflects the company's ultimate pursuit of product quality, but also provides reliable guarantees for cable laying in multiple industries such as electricity and transportation, and establishes a good brand image in market competition.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt