If you need any help, please feel free to contact us

Jiangsu Youming Group Co., Ltd. was established in 2015 and is located in the Taidong Industrial Park, Shiyuan Town, Dongtai City. It is a enterprise specializing in the research and development and production of cable trays. It is a innovative high-tech enterprise in Jiangsu Province. With a registered capital of 50 million RMB, it covers an area of 60 acres and has a production workshop of over 26,000 square meters, with an annual production capacity of more than 30,000 tons of cable trays.

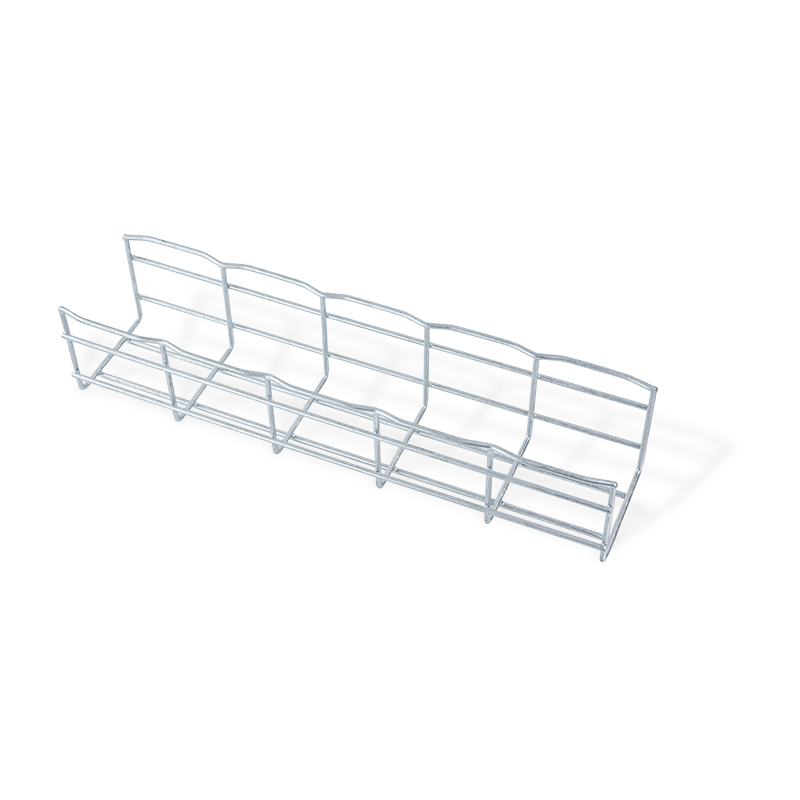

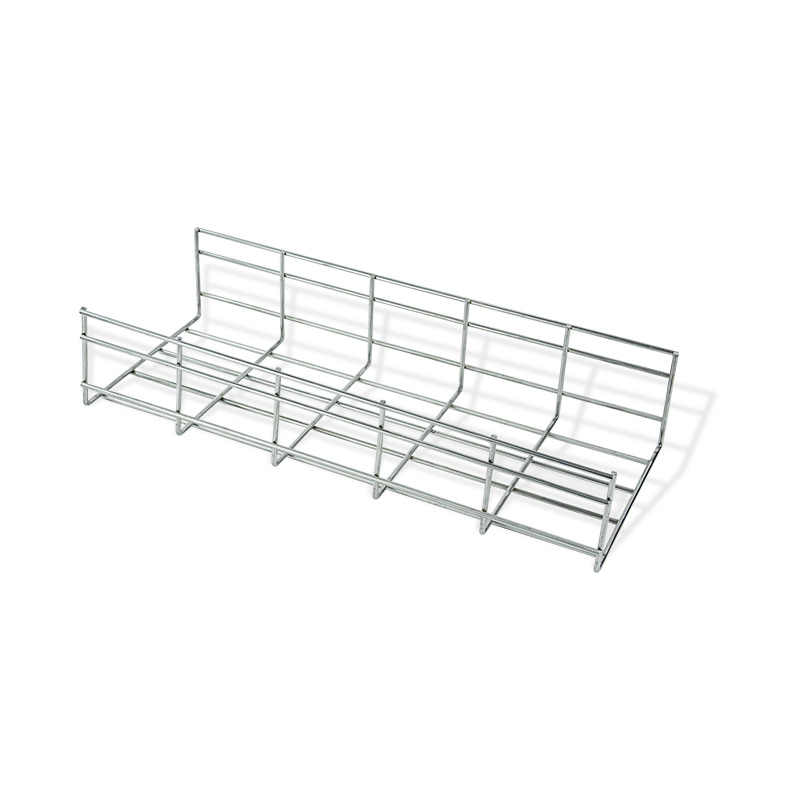

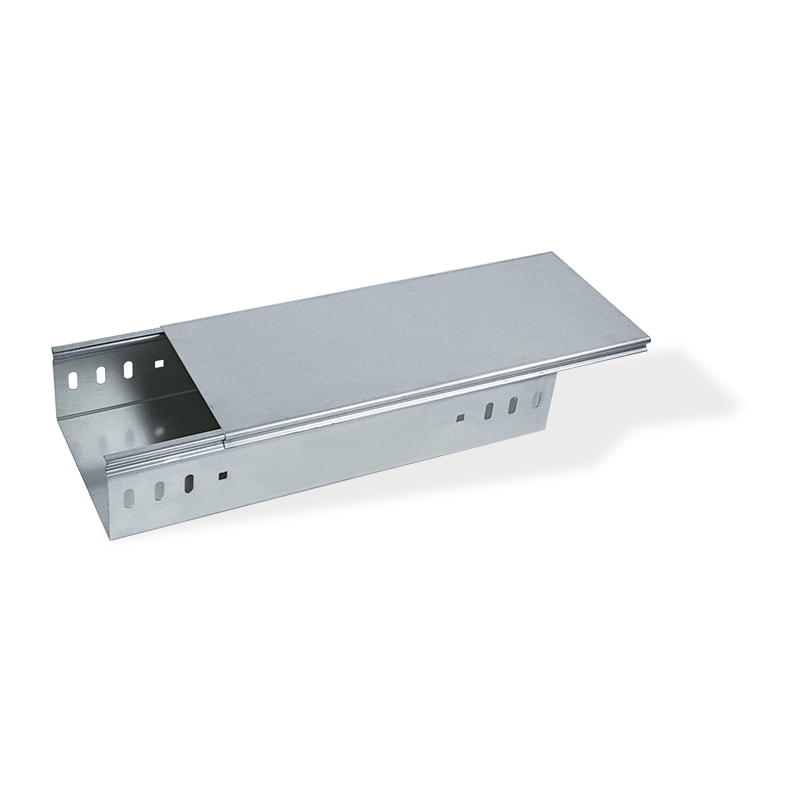

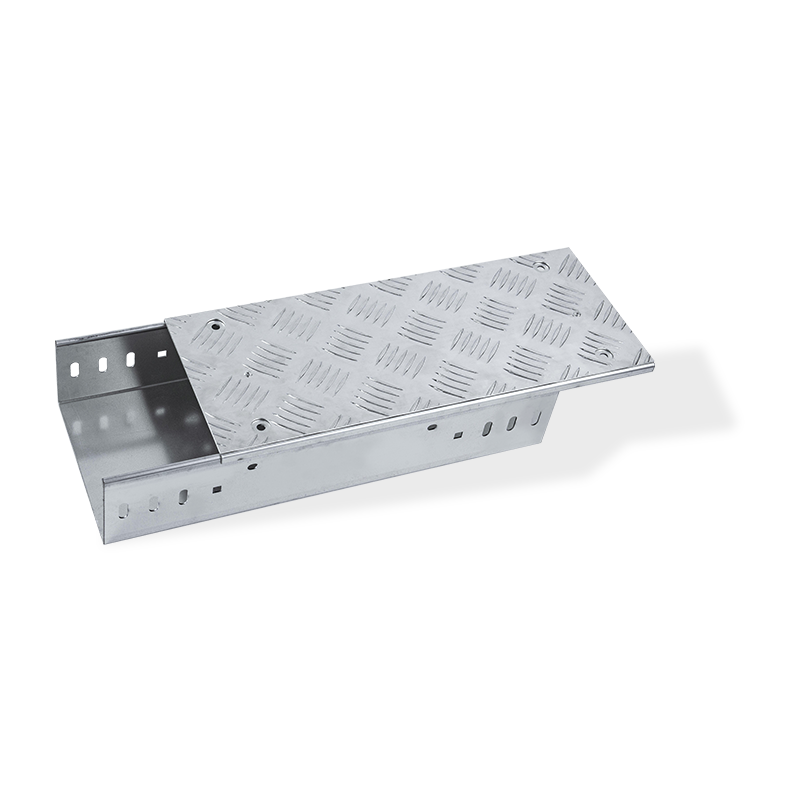

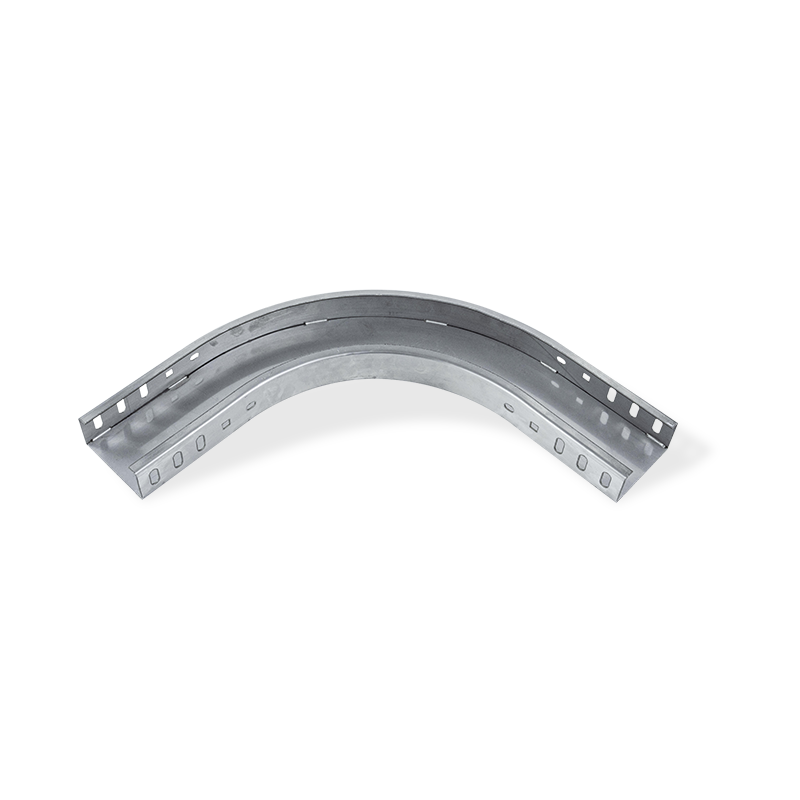

In the increasingly refined cable tray market, the company has steadily advanced to the forefront of the industry, equipped with fully automatic production lines. Its main include longitudinal and transverse shearing lines, automatic forming lines, automatic welding lines, automatic riveting lines, laser cutting and CNC turret punching lines, and automatic spraying lines. The products are mainly divided into several series such as stainless steel, aluminum alloy, hot-dip galvanized, and powder-coated/fireproof, and various specifications and models such as trough type, ladder type, perforated type, and mesh type. The products are widely used in infrastructure, transportation, communication, power (including wind, photovoltaic and thermal power, machinery, metallurgy, shipping, chemical, pharmaceutical, food and other fields. The company has its own testing center, and every test from raw material procurement to product delivery undergoes quality inspection, ensuring that the product quality reaches the high level in the industry. After years of market expansion, it has established good cooperative relationships with many famous domestic enterprises, providing customers with comprehensive product selection services and winning high recognition and trust from customers.

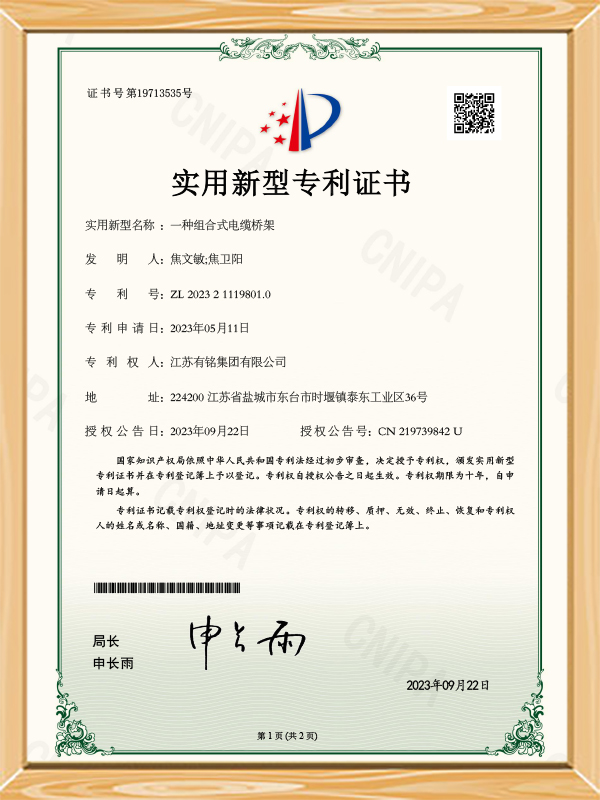

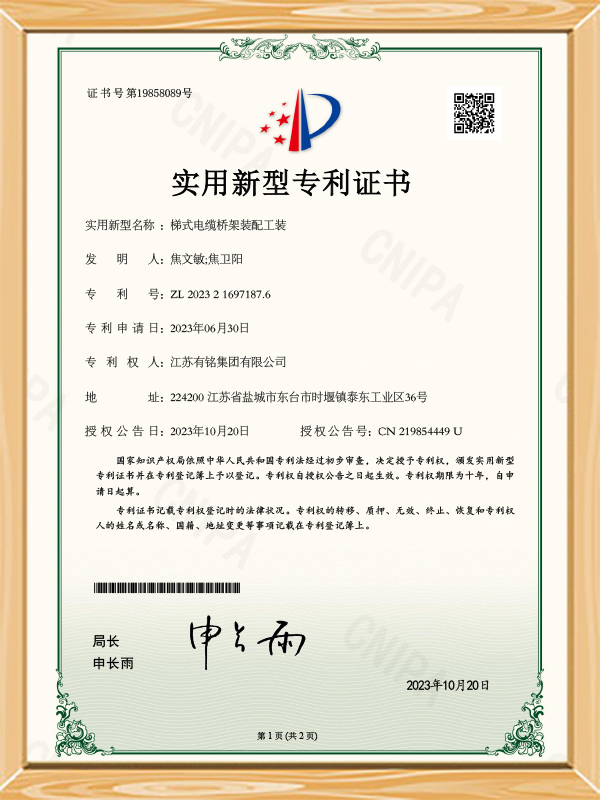

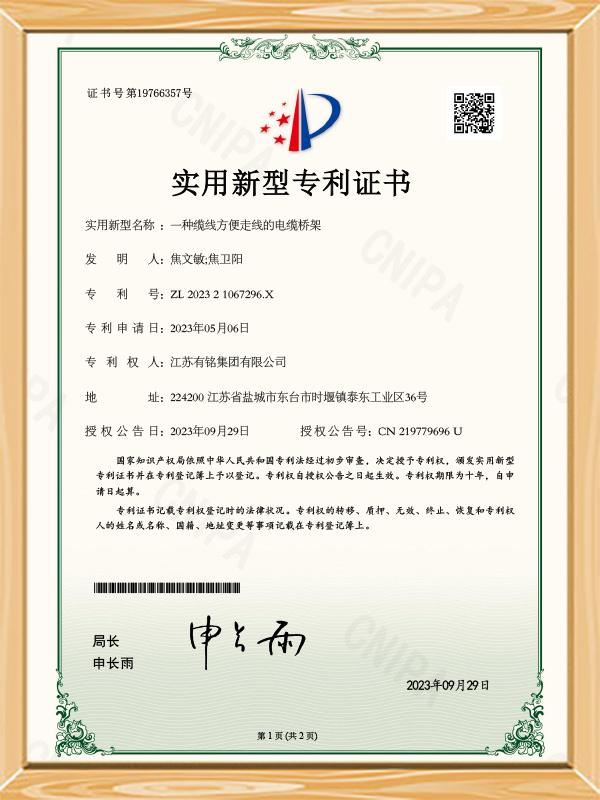

The company attaches great importance to production and technological research and development and innovation. With talent and technology as the guarantee, it has over 150 skilled employees, including more than 50 technical backbone members. It has a design and R&D team, advanced enterprise management, and an efficient sales team. The company has passed the ISO 9001:2015 quality management system standard certification, ISO 14001:2015 environmental system standard certification, ISO 45001:2018 occupational health and safety system standard certification, and EU CE certification It has obtained multiple independent intellectual property rights and patent technologies and is in a high position in technological innovation in the industry.

Introduction to Aluminum Alloy Cable Trays Aluminum alloy cable trays are essential components in modern electrical systems, offering superior durability, lightweight design, and resistance to corrosion. They are widely ...

Introduction: Why Choose Anti-slip Stainless Steel Cable Tray? In modern industrial and architectural fields, cable management is of paramount importance. It not only concerns the normal operation of systems but also di...

In the demanding world of marine and offshore engineering, the integrity of electrical and data cable management is non-negotiable. Selecting the right support system is critical for safety, reliability, and longevity. T...

Durability upgrade: Performance advantages of plastic spray cable tray series in corrosive environments

In highly corrosive environments such as industry, ocean, and chemical industry, traditional metal cable trays often have a shortened life due to rust, aging, and other problems, and the maintenance cost remains high. The cable tray using plastic spray-coating technology has significantly improved corrosion resistance and durability through the protection of high-performance polymer coatings, becoming an ideal solution for harsh environments.

Core technology of plastic spray cable trays

The manufacturing process of plastic spray cable trays mainly includes substrate surface treatment (such as sandblasting, phosphating) and electrostatic spraying or high-temperature cladding coating (such as epoxy resin, polyester, PVC, etc.). Its key performance indicators include coating thickness (usually ≥80μm), adhesion (verified by cross-grid test) and impact resistance (in accordance with ASTM D2794 standard). These technologies ensure the long-term stability of the bridge in complex environments.

Performance advantages in corrosive environments

Chemical corrosion resistance

Plastic spray cable trays can resist erosion by chemical media such as acids, alkalis, and salt spray. For example, coatings that pass the ISO 9227 salt spray test can ensure long-term use in coastal or chemical environments, while traditional galvanized bridges are prone to electrochemical corrosion in chloride ion environments, causing the protective layer to fail quickly.

Resistance to heat and humidity

The hydrophobic and insulating properties of the coating itself effectively block moisture penetration and prevent the metal substrate from rusting in a humid environment. In contrast, the corrosion rate of unprotected metal bridges is significantly accelerated under hot and humid conditions.

Anti-UV aging ability

Plastic spray bridges with anti-ultraviolet agents can maintain stability for more than 10 years in outdoor exposure environments, while traditional metal bridges need to be regularly repainted with protective paint, which has higher maintenance costs.

Mechanical strength and durability

Plastic spray technology not only provides anti-corrosion protection, but also synergizes with the metal substrate to enhance the overall mechanical properties. For example, modified polyethylene coatings can improve the impact resistance and wear resistance of bridges, while traditional metal bridges are prone to embrittlement or deformation after the coating peels off.

Typical application scenarios

Chemical industry: A sulfuric acid plant uses epoxy spray bridges, which show no signs of corrosion within 5 years, while the original galvanized bridges need to be replaced after only 2 years of use.

Coastal data center: Data centers in high salt fog areas use polyester spray bridges, which extend their life to 8 years and reduce the overall cost by 30%.

Sewage treatment plant: PVC spray bridges show excellent stability in environments with fluctuating pH values, greatly reducing maintenance frequency.

Selection and construction recommendations

Coating selection

Epoxy resin: Suitable for strong acid and strong alkali environments (such as petrochemical and pharmaceutical industries).

Polyester: High cost-effective, suitable for general industrial environments or moderate corrosion conditions.

PVC: Resistant to moisture and chemical corrosion, commonly used in sewage treatment or food processing.

Installation precautions

Avoid mechanical damage to the coating during construction. If cutting or drilling, the exposed parts need to be sprayed for protection.

Sealants or rubber gaskets should be used at the connection points to prevent crevice corrosion.

Check the integrity of the coating regularly and repair local damage in time to extend the service life.

English

English русский

русский Español

Español Português

Português Deutsch

Deutsch عربى

عربى italiano

italiano Türk

Türk हिंदी

हिंदी bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt